- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2400*1900*700MM

-

Application:

-

wooden shop

-

Weight (KG):

-

190 KG

-

Power (kW):

-

1000

-

Max.Cutting Height at 90°(mm):

-

1250mm

-

Max.Cutting Height at 45°(mm):

-

23mm

-

Max. Length of Workpiece (mm):

-

2400mm

-

Marketing Type:

-

New Product 2022

-

NAME:

-

HAOBAI

Quick Details

-

Place of Origin:

-

guangdong

-

Brand Name:

-

HAOBAI

-

Usage:

-

WOODEN

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2400*1900*700MM

-

Application:

-

wooden shop

-

Weight (KG):

-

190 KG

-

Power (kW):

-

1000

-

Max.Cutting Height at 90°(mm):

-

1250mm

-

Max.Cutting Height at 45°(mm):

-

23mm

-

Max. Length of Workpiece (mm):

-

2400mm

-

Marketing Type:

-

New Product 2022

-

NAME:

-

HAOBAI

Installation Instructions

1. Expand the panel saw and align it up and down, first connect the lower angle iron

and the frame with screws.

and the frame with screws.

2. Put the machine head on the frame, align the optical axis with the slider of the

machine head, put it in the middle and then pass through the lower angle iron optical

axis support seat for 6 cm

machine head, put it in the middle and then pass through the lower angle iron optical

axis support seat for 6 cm

3. Connect the upper angle iron and the frame with screws, pull the optical axis up

and pass it into the support seat, and tighten the optical axis seat screws with the

hexagon socket.

and pass it into the support seat, and tighten the optical axis seat screws with the

hexagon socket.

4. Align the notch on the top of the pressure rod with the slider nut on the cylinder,

cover one end first and then the other end, and fix it with the flattening screw. Put the

fixed pulley on the middle screw hole of the angle iron and align it properly, and fix it

with self-tapping screws.

cover one end first and then the other end, and fix it with the flattening screw. Put the

fixed pulley on the middle screw hole of the angle iron and align it properly, and fix it

with self-tapping screws.

5. Put the machine upright against the pillar or the corner of the counterweight iron

wire, and hook it on the machine head hasp from the back through the fixed pulley.

Attach the saw blade and pointer.

wire, and hook it on the machine head hasp from the back through the fixed pulley.

Attach the saw blade and pointer.

6. Connect the compressed air pipe to the electronic valve. The two adjustable exhaust

valves of the electronic valve can adjust the speed of the pressure rod pressing plate

and the speed of releasing the pressure rod.

valves of the electronic valve can adjust the speed of the pressure rod pressing plate

and the speed of releasing the pressure rod.

7. Hang up the vacuum cleaner, put the vacuum cleaner tube on the vacuum hood of

the machine head, put the tube and wire together with tape, the tube is elastic, pull the

machine head up and down to make it slide freely, and it can work.

the machine head, put the tube and wire together with tape, the tube is elastic, pull the

machine head up and down to make it slide freely, and it can work.

Products Description

Precautions for the use of panel saws

1. The machine must be grounded before starting. Carefully check whether the saw

blade pad, compression nut and screws in various parts are firm. If any looseness is

found, it should be tightened in time. When installing the saw blade, pay attention to

the cutting direction, which is irreversible.

2. First cut a small board and measure it with a ruler. If it is not accurate, fine-tune it

to avoid processing errors.

3. When cleaning the machine, inserting lubricating oil, disassembling and replacing

saw blades and removing sawdust, the power must be cut off first.

4. When cutting horizontally, the flat plate should be pushed smoothly in the cutting

direction, and no one should stand. The material of Party B will fly out and hurt

people.

5. When a fault occurs, immediately cut off the power supply, stop the operation,

repair and adjust the machine, and do not operate with a fault.

1. The machine must be grounded before starting. Carefully check whether the saw

blade pad, compression nut and screws in various parts are firm. If any looseness is

found, it should be tightened in time. When installing the saw blade, pay attention to

the cutting direction, which is irreversible.

2. First cut a small board and measure it with a ruler. If it is not accurate, fine-tune it

to avoid processing errors.

3. When cleaning the machine, inserting lubricating oil, disassembling and replacing

saw blades and removing sawdust, the power must be cut off first.

4. When cutting horizontally, the flat plate should be pushed smoothly in the cutting

direction, and no one should stand. The material of Party B will fly out and hurt

people.

5. When a fault occurs, immediately cut off the power supply, stop the operation,

repair and adjust the machine, and do not operate with a fault.

VIDEO

.

Product packaging

FAQ

1. who are we?

We are based in Guangdong, China, start from 2017,sell to Eastern Asia(10.00%),Mid East(10.00%),Northern Europe(10.00%),Central,America(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),South America(10.00%),North America(10.00%),Domestic ,Market(5.00%),Africa(5.00%),South Asia(5.00%),Western Europe(2.00%),Southern Europe(2.00%),Oceania(1.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

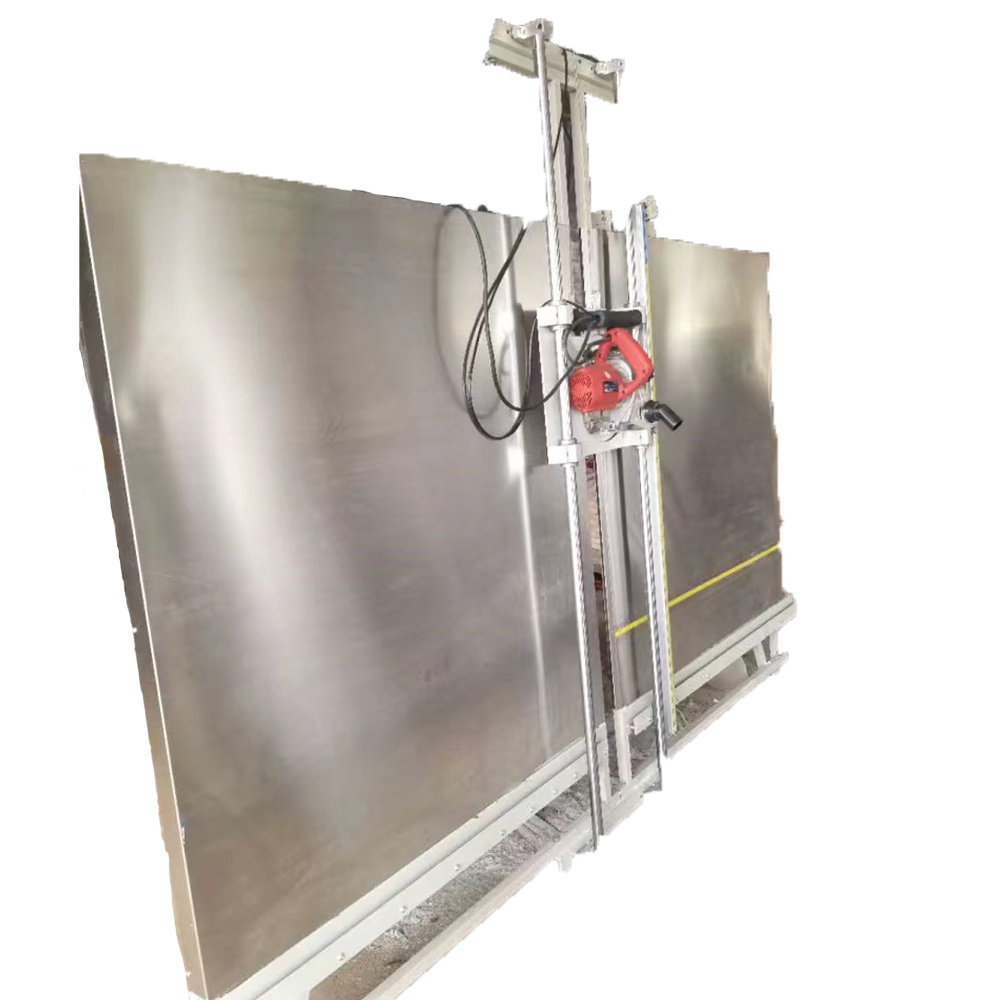

Vertical Panel Saw

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,MoneyGram,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

We are based in Guangdong, China, start from 2017,sell to Eastern Asia(10.00%),Mid East(10.00%),Northern Europe(10.00%),Central,America(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),South America(10.00%),North America(10.00%),Domestic ,Market(5.00%),Africa(5.00%),South Asia(5.00%),Western Europe(2.00%),Southern Europe(2.00%),Oceania(1.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

Vertical Panel Saw

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,MoneyGram,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Hot Searches