- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Enqi

-

Color:

-

black , white , green or optional

-

Teeth Type:

-

StraightHelical

-

Lead Time:

-

7-10 working day

-

Business type:

-

OEM Manufacure

-

Drawing Format:

-

jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc

-

Hardness:

-

HRC 53-58

-

OEM/ODM:

-

acceptable

-

Application:

-

Industrial

-

MOQ:

-

1 Piece

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

dke-d3d

-

Brand Name:

-

Enqi

-

Color:

-

black , white , green or optional

-

Teeth Type:

-

StraightHelical

-

Lead Time:

-

7-10 working day

-

Business type:

-

OEM Manufacure

-

Drawing Format:

-

jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc

-

Hardness:

-

HRC 53-58

-

OEM/ODM:

-

acceptable

-

Application:

-

Industrial

-

MOQ:

-

1 Piece

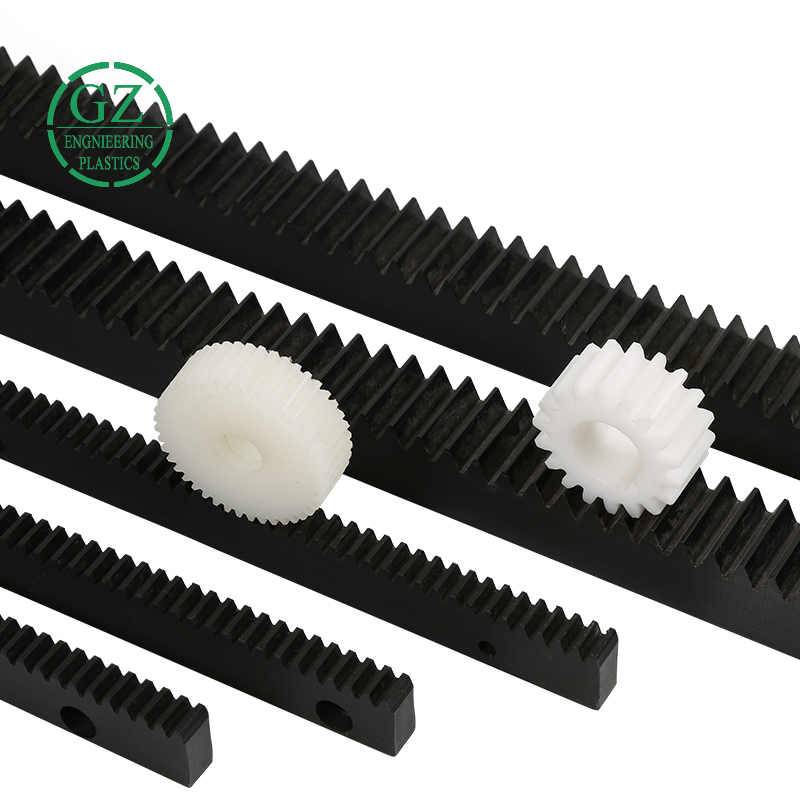

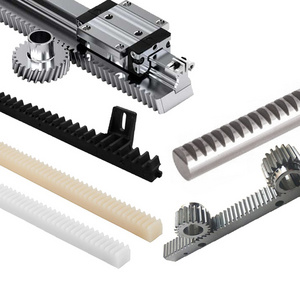

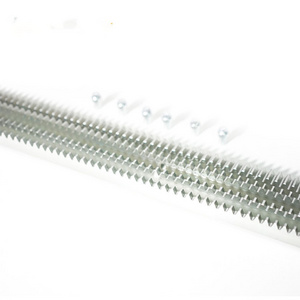

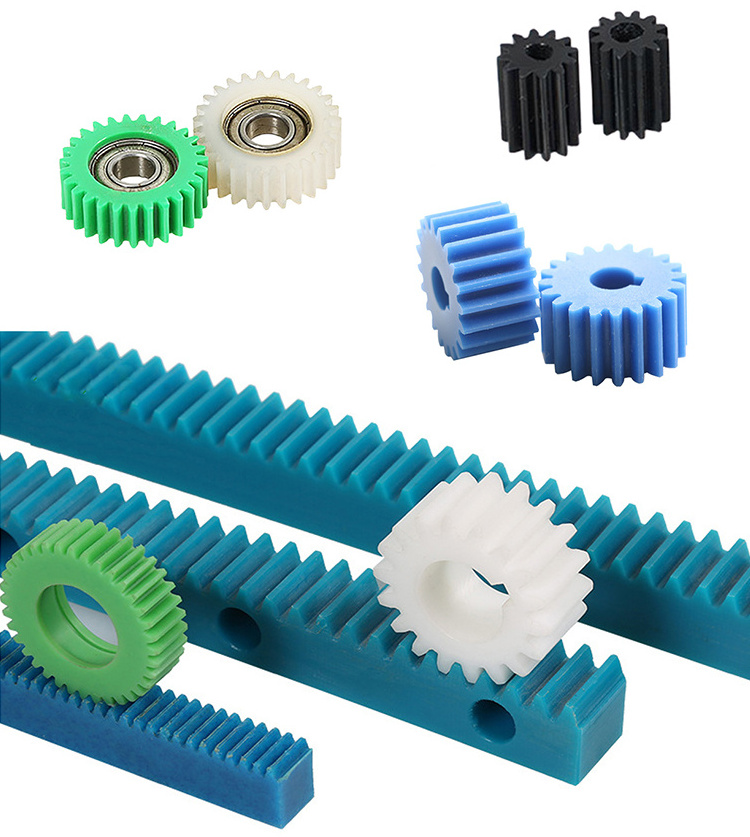

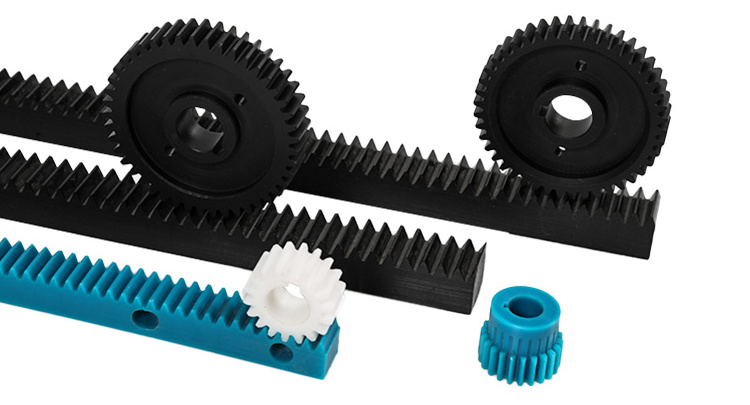

custom spur cnc plastic nylon pom flexible gear rack and pinion for linear motion

Guangdong Enginnering Plastics Industries (Group) co., Ltd established in January 2009 , is a professional production of "engineering plastics accessories" high-tech enterprises. Company main products : UHMW-PE , MC Nylon , PA6 , POM, HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic, PEEK, PPS , PTFE , PVDF , PAI, PEI , PSU , PI, PBI Antistatic product series .

Company also provide wide range of accessories processing conditions , such as mass customization production ability ,exquisitemanufacturing technology and advanced production equipment , professional technical advice and after-sales service.

Companies strictly enforce the ISO9001(2008) International quality certification system , the product quality conforms to the EU Rohs standard .

|

Rack Material

|

UHMW-PE, Nylon, POM, HDPE or according customer's requirement

|

|

|

|

|||

|

Rack Color

|

Green,blue or customized

|

|

|

|

|||

|

Rack Techniques

|

High precision 3-axis CNC and cnc milling machine

|

|

|

|

|||

|

Rack Feature

|

1. Wear resistant;

|

|

|

|

|||

|

|

2. Impcat resistant;

|

|

|

|

|||

|

|

3. Easily machined.

|

|

|

|

|||

|

Rack Standard Size

|

customized according to drawing

|

|

|

|

|||

|

Rack Application

|

Link chain,machine tool,etc.

|

|

|

|

|||

|

Payment

|

50% T/T in advance, 50% T/T before delivery

|

|

|

|

|||

|

Place of origin

|

GuangZhou, China (Mainland)

|

|

|

|

|||

|

Delivery

|

According to the orders, usually 5-15 days

|

|

|

|

|||

Prduct Display

1.Thread H4 fine car grade tolerance 4H fine car grade production, vertical accuracy 0.005mm.

2.High strength steel hardness HRC28, phosphoric acid plating on the surface and after lubricationEach lock nut is provided with independent packaging to ensure quality.

durable

Fine raw

material

Carefully select the product

raw materials manufacturing

assured

quality

Good impact

resistance

Our Factory

The factory covers an area of 10,000 square meters Production equipment has the original American imported Haas CNC machining center, wire-electrode cutting, electrical discharge machine,Perforating machine, injection molding machine, CNC milling machine CNC

hobbing machine, CNC lathe, CNC milling machine CNC lathe, CNC milling machine, grinding machine and other machinery and equipment.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu

RoHS standard.

Professional Team

Guangdong Engineering Plastics Industries Co., Ltd! We have the professional engineer teams and sales teams, and we have

technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in Huangpu District,

Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support

technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in Huangpu District,

Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support

personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines.

We can customize all kinds of Engineering plastics products according to our

customers’drawings or samples.

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Client Witness

Our Exhibition & CCTV Interview

Application

Cooperation

FAQ

Q1. Can only samples be produced?

A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different

equipment has different accuracy, generally between 0.05-0.1

equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,

electroplating, etc.

electroplating, etc.

Hot Searches