1. Double transducer control, flexible bag length cutting, operator needn’t to adjust the unloading working, saving time and saving films.

2. human-machine operation, convenient and quick parameter setting.

3.Self diagnosis failure function, clear failure display.

4. High sensitivity optical electric color mark tracking ,digital input cut position which makes the sealing and cutting more accurate.

5. Separate PID control to temperature, suitable for various packing materials.

6. Stopping the machine in selected position, no sticking to the knife and no waste packing film.

7. Simple driving system, reliable working, convenient maintenance.

8. .All the controls are achieved by software, convenient for function adjusting and upgrading.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

380

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

taichuan

-

Dimension(L*W*H):

-

3770x720x1450 mm

-

Product name:

-

Horizontal Packaging Machine

-

Bag type:

-

Back Sealing

-

Usage:

-

Soft Pouch Packing

-

Keyword:

-

High Speed

-

Main Function:

-

Weighing Forming Filling Sealing

-

Packing speed:

-

40~230 Bags/min

-

Feature:

-

High Level High Speed

-

Advantage:

-

Stable Operation

-

Automaticity:

-

Fully Auto

Quick Details

-

Function:

-

FILLING, Sealing, SLITTING

-

Packaging Type:

-

Cartons, Bags, Film, Foil, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

380

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

taichuan

-

Dimension(L*W*H):

-

3770x720x1450 mm

-

Product name:

-

Horizontal Packaging Machine

-

Bag type:

-

Back Sealing

-

Usage:

-

Soft Pouch Packing

-

Keyword:

-

High Speed

-

Main Function:

-

Weighing Forming Filling Sealing

-

Packing speed:

-

40~230 Bags/min

-

Feature:

-

High Level High Speed

-

Advantage:

-

Stable Operation

-

Automaticity:

-

Fully Auto

Product Description

|

Type

|

TCZB-250

|

TCZB -350

|

TCZB -450

|

|

Film width

|

250MM

|

350MM

|

450MM

|

|

Bag Length

|

65-280MM

|

65-280MM

|

130-450MM

|

|

Bag width

|

30-110mm

|

50-160MM

|

60-200mm

|

|

products High

|

Max.40mm

|

Max.45mm

|

max 80mm

|

|

Packing speed

|

40-230bag/mins

|

40-230bag/min

|

30-180bag/min

|

|

Power

|

220V 50/60HZ 2.4KW

|

220V 50/60HZ 2.6KW

|

220v 50/60hz 2.6KW

|

|

Machine size

|

3770x670x1450

|

3770x720x1450

|

4020x820x1450mm

|

|

Machine Weight

|

550kg

|

600kg

|

800kg

|

Main performance and structure features

Bags&Materials

Details Images

Easy Control Touch Screen

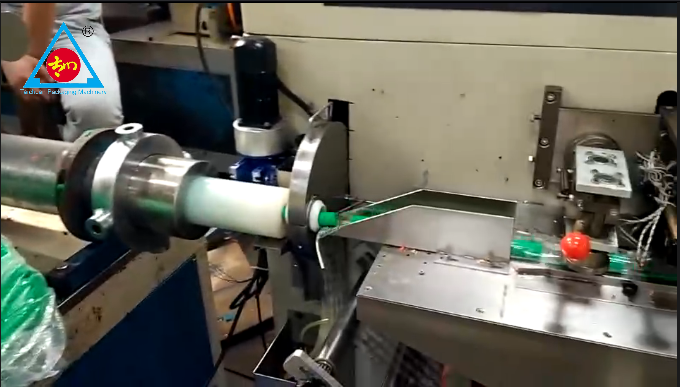

Feeding System

1.Origin: China

2.Full automatic to feeding and weighing and cutting to package.

Bag former

1.Origin: China

2.

Full 304SS Conveyor

3.Machine conveyor is made of 304 stainless steel ,Health and Safety Durable feed by manually or automatically

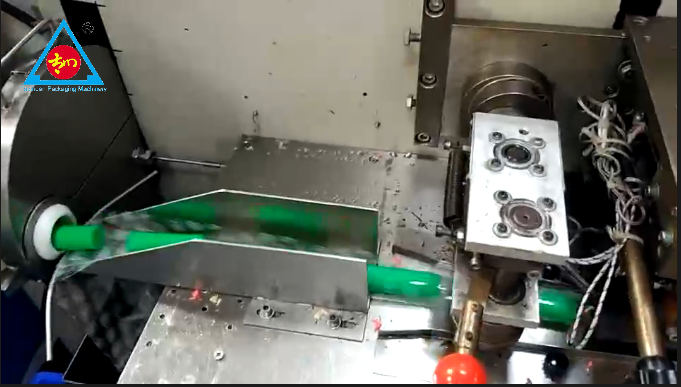

Hot Pressing Middle Seal Area

Origin: China

Independent PID temperature control ,heating the double turntable seal ,sealing the back of the packaged product, guaranteed sealing .

End Seal Cutting Area

Origin: China

Rotate the constant temperate heat sealing cutter to seal the front and rear ends of the packaged product and avoid curling or

llopholes in the sealing position.

llopholes in the sealing position.

Packing & Delivery

The wooden case is customized according to the dimension of the machine for the long time

shipping and transfering.

Shipping a whole set of the machine:

1. Preparing and checking the toolbox wearing part and the manual book.

2.Cleaning the dust and the scrap after testing the machine with the air pump.

3. Disassemble some certain part of the machine.

4. All the disassemble part, toolbox, main machine wrap by film

5.There will have screw fix themachine at the bottom of the wooden case

shipping and transfering.

Shipping a whole set of the machine:

1. Preparing and checking the toolbox wearing part and the manual book.

2.Cleaning the dust and the scrap after testing the machine with the air pump.

3. Disassemble some certain part of the machine.

4. All the disassemble part, toolbox, main machine wrap by film

5.There will have screw fix themachine at the bottom of the wooden case

6.If any special requirements, we will pack it as requested.

A small spare part: Wrapped by the film that delivered by the DHL,UPS,TNT,EMS etc.

A small spare part: Wrapped by the film that delivered by the DHL,UPS,TNT,EMS etc.

Payment And Shipping

1.T/Tand Western Union are accepted

2.30% deposit before production and 70% balance before shipment

3.All banking charges outside China are on buyers

Shipping

1.Upon receipt of payment , delivery date will be in 15-30 working days,

2.By Air, by Sea or by Express (DHL etc)

3 .Shipment cost will depend on the destination, shipment way and the weight of the goods

1.T/Tand Western Union are accepted

2.30% deposit before production and 70% balance before shipment

3.All banking charges outside China are on buyers

Shipping

1.Upon receipt of payment , delivery date will be in 15-30 working days,

2.By Air, by Sea or by Express (DHL etc)

3 .Shipment cost will depend on the destination, shipment way and the weight of the goods

Contact us

Hot Searches