- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Design Style:

-

Industrial

-

Place of Origin:

-

Hanoi, Vietnam

-

Brand Name:

-

DHM

-

Model Number:

-

XPS

-

Type:

-

XPS Board

-

Size:

-

10-80mm Thick ,width 600mm ,length can be customized

-

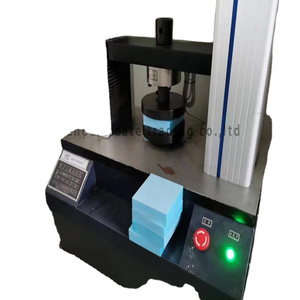

Compressive Strength:

-

350kpa

-

Water Absorption:

-

≤1%(v/v)

-

Function:

-

Thermal Preservation

-

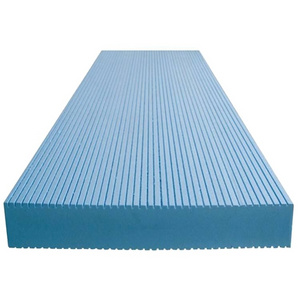

Color:

-

Blue, Blue Flame Retardant Foam Board

-

Material:

-

Polystyrene, XPS Wall Insulation

-

Density:

-

333Kg/m3 Exterior Wall Insulation Extruded Board

-

Thermal Conductivity:

-

≤0.03w/(m.k)

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Apartment

-

Design Style:

-

Industrial

-

Place of Origin:

-

Hanoi, Vietnam

-

Brand Name:

-

DHM

-

Model Number:

-

XPS

-

Type:

-

XPS Board

-

Size:

-

10-80mm Thick ,width 600mm ,length can be customized

-

Compressive Strength:

-

350kpa

-

Water Absorption:

-

≤1%(v/v)

-

Function:

-

Thermal Preservation

-

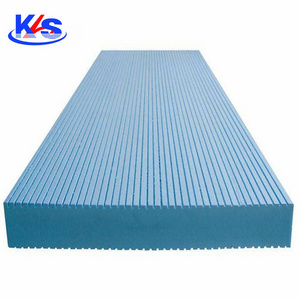

Color:

-

Blue, Blue Flame Retardant Foam Board

-

Material:

-

Polystyrene, XPS Wall Insulation

-

Density:

-

333Kg/m3 Exterior Wall Insulation Extruded Board

-

Thermal Conductivity:

-

≤0.03w/(m.k)

Product Description

|

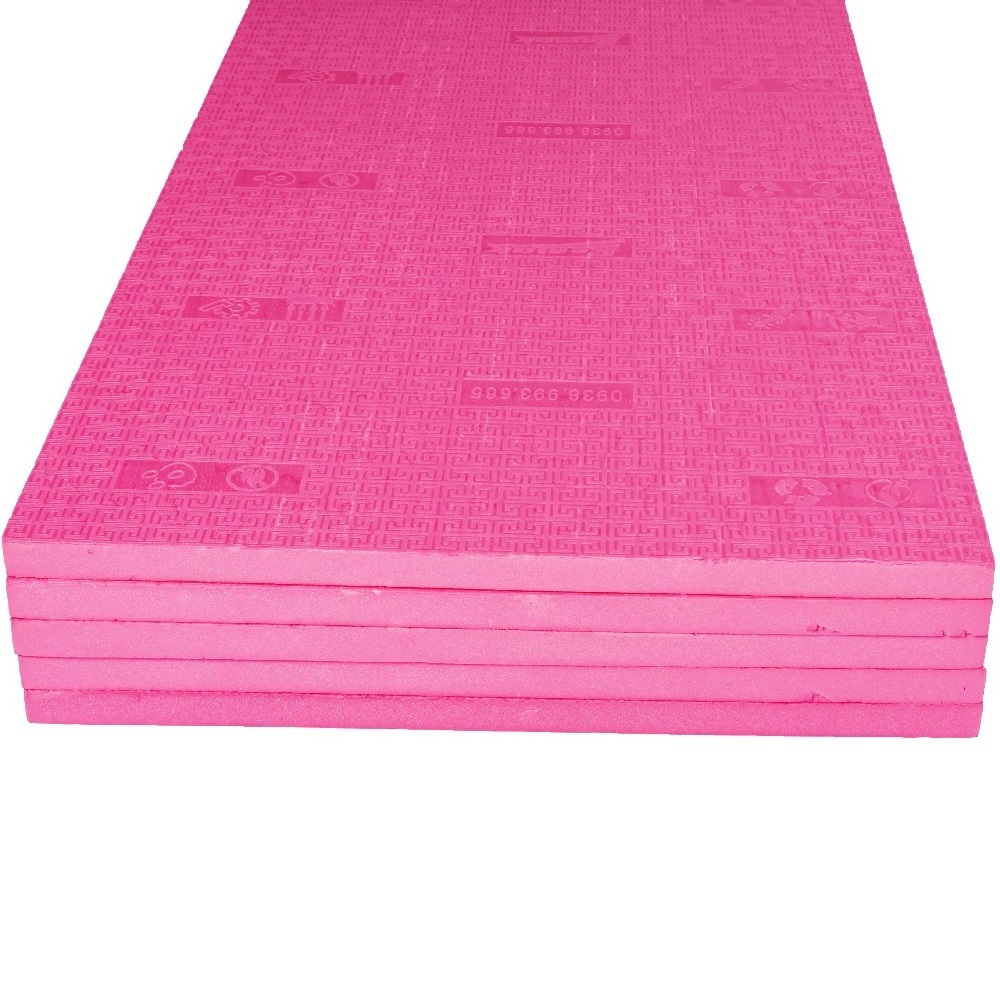

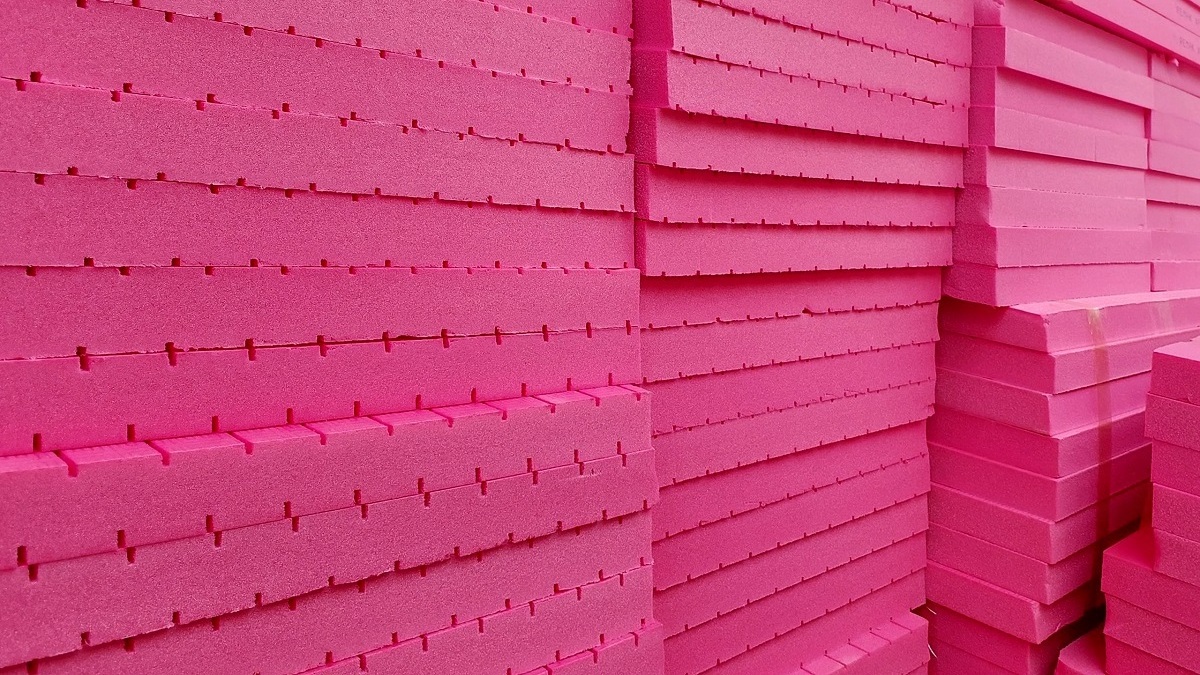

XPS Insulation Foam Board

|

|

|

|

Thickness

|

10-100mm

|

|

|

Density

|

25-35kg/m3

|

|

|

Witdth

|

600/1200/1220mm

|

|

|

Length

|

Customize ,less than 6m

|

|

|

Compressive strength

|

300-1200 kPa

at 10% deflection or yiels, (vertical)

|

|

|

Tensile strength

|

≥300 kPa

|

|

|

Water absorption (Vol-%)

|

≤1.00%

|

|

|

Combustion performance

|

B1/B2

|

|

|

Temperature limits

|

-50℃~70℃

|

|

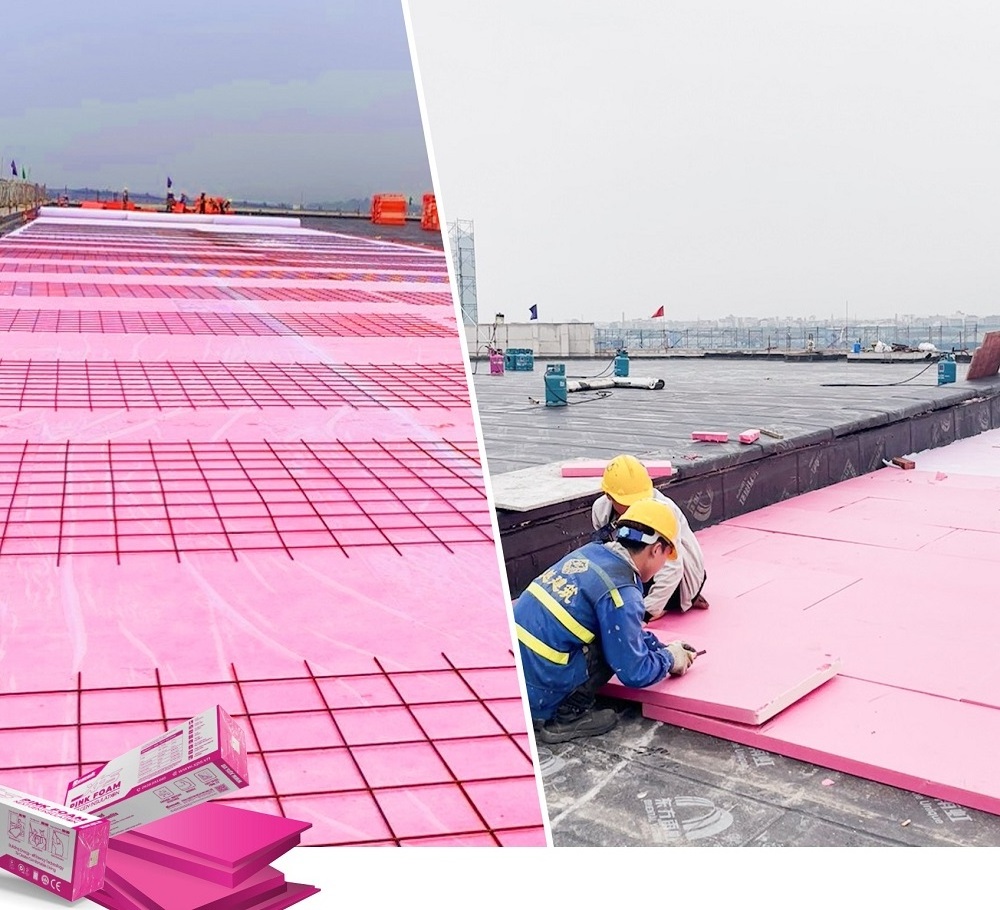

1.

Impermeable and waterproof, with stable performance

In the construction of cold storage, extruded plastic panels are essential. It not only plays a role in thermal insulation, but also due to the microporous structure on the surface of the extruded board, it can absorb and buffer a small amount of water vapor condensation, reducing the formation of water droplets. High requirements for extruded plastic panels for cold storage, with a thickness of over 10 centimeters. So in the construction of cold storage, two layers of extruded panels are usually used. One is to increase the thickness, and the other is to stagger and splice the two layers of extruded panels to increase insulation and avoid temperature loss.

2.

Easy construction and low cost

The closed cell honeycomb structure of extruded panels can ensure good insulation, waterproofing, and moisture-proof effects with only a very thin layer, and is limited by the indoor floor height. For home decoration, the thinner the foundation, the larger the indoor space.

3. Thermal insulation, energy saving & environmental protection

XPS extruded board is suitable for environments where high compression resistance is required for insulation layers. It has been widely used in wall insulation, concrete roofs, steel roof insulation, low-temperature storage floors, parking platforms, airport runways, highways and other fields

DHM's Insulation Foam Board

Applications

Hot Searches