1.

Tube expanding, end flaring and flanging

are done in one process.

2. Expanding rods can be secured quickly. A protection mechanism prevents damage to the expanding rod.

3.

Highly automated

, which reduces labor intensity.

4. The machine can run for 24 hours each day with sound performance. Its low failure rate allows for mass production.

5. The design takes ergonomics into consideration. The machine is

easy to operate

, requiring only low maintenance. The noise level is low.

6. In the case of failure, the control panel screen will display causes and provide solutions, to enhance efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

tube expander

-

Color:

-

Customer's Requirement

-

Material:

-

Cast Iron

-

Expander Type:

-

Vertical

-

Tube Material:

-

Soft Copper tube

-

Max. length of effective expanding tube:

-

200-1200 mm

-

Guide Column No.:

-

2

-

Max. expand tube layout size:

-

90*960mm

-

Special wide type:

-

132*1260mm

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

smac

-

Weight (KG):

-

10

-

Usage:

-

tube expander

-

Color:

-

Customer's Requirement

-

Material:

-

Cast Iron

-

Expander Type:

-

Vertical

-

Tube Material:

-

Soft Copper tube

-

Max. length of effective expanding tube:

-

200-1200 mm

-

Guide Column No.:

-

2

-

Max. expand tube layout size:

-

90*960mm

-

Special wide type:

-

132*1260mm

Recommend Products

Products Description

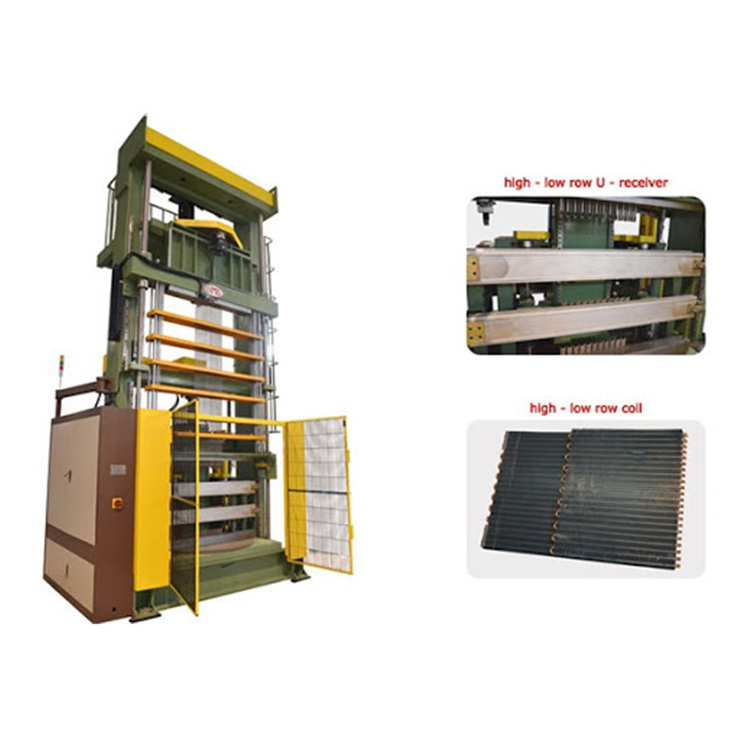

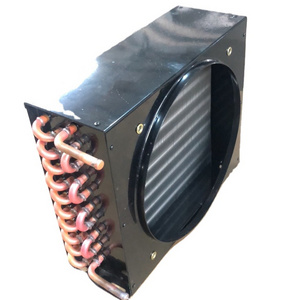

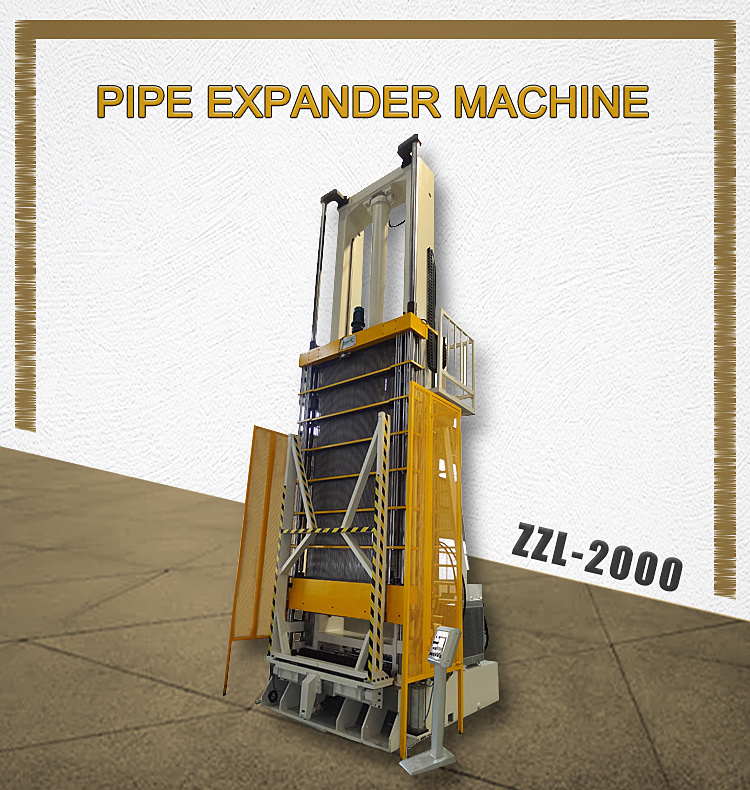

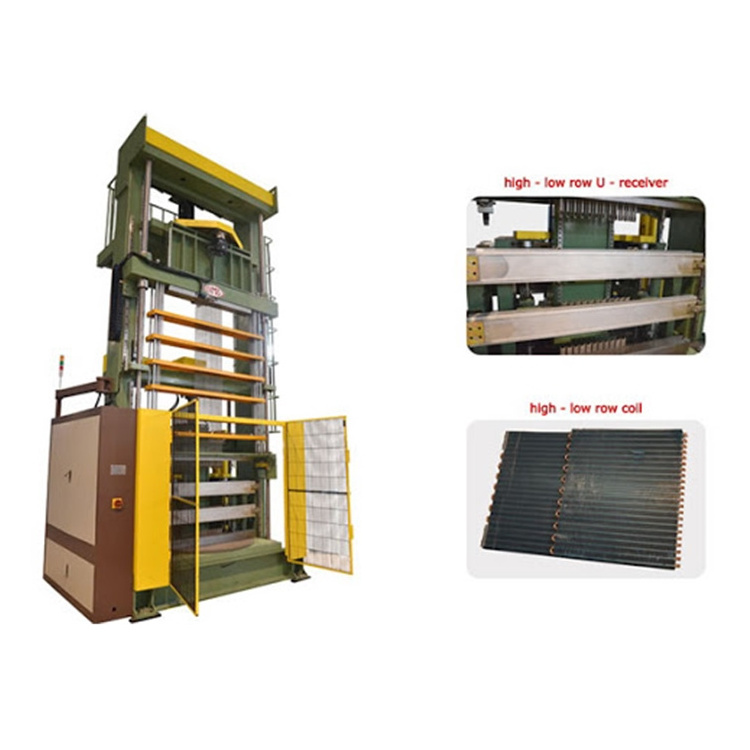

Vertical tube expander

vertical tube expander is designed for the production of heat exchangers coils. By expanding, the copper tubes are closely fitted with the aluminum fins, so as to realize higher heat exchange efficiency. The machine is easy to operate, of high precision, and reliable. It has the following major characteristics:

Action cycle

Expander machine is composed of the basement, column device, guided expansion device, hydraulic station system, electrical system, pneumatic system components. Action cycle is as follows:

put the workpiece in place by manual → close the door and lock work piece → automatic expanding the tube, flaring, flanging, expansion tube reset → open the door → take out the work piece.

Parts:

The base device is mainly composed of the base body, the hydraulic station part

The column device is mainly composed of the column body, the main cylinder, the main cylinder transmission part, the workpiece locking door part, the length adjustment part of the expansion pipe, and the escalator.

The Guided expansion device is mainly composed of the power seat part, the expansion rod guide plate part, the expansion mouth part, the return material part, the expansion rod assembly, the guide column part etc.

Specifcation

|

S.N

|

Item

|

Technical parameter

|

Remark

|

|

1

|

Expander Type

|

Vertical

|

Top built hydraulic cylinder expander

|

|

2

|

Tube Material

|

Soft Copper tube

|

or soft Aluminum

|

|

3

|

Max. length of effective expanding tube mm mm

|

200-1200

|

|

|

4

|

Guide Column No.

|

Two

|

4 for optional

|

|

5

|

Max. expand tube layout size mm mm

|

90×960

|

170×960

|

|

|

Standard size

|

132×960

|

215×960

|

|

6

|

Max. expand tube layout size mm mm

|

90×1060

|

170×1060

|

|

|

Wide type

|

132×1060

|

215×1060

|

|

7

|

Max. expand tube layout size mm

|

90×1260

|

170×1260

|

|

|

Special wide type

|

132×1260

|

215×1260

|

Hot Searches