- Product Details

- {{item.text}}

Quick Details

-

Power:

-

13kw

-

Dimension(L*W*H):

-

12700*1580*1500mm

-

Weight:

-

2500 KG

-

Machinery Function:

-

Baguette, Rye bread, Pita Bread, Focaccia, Ciabatta, White bread, Multigrain bread, Bagel, Brioche, Whole wheat bread, Bread roll, Bun, Challah

-

Output product name:

-

Diverse Bread

-

Product name:

-

bread production line

-

Usage:

-

bread manufacturing machines

-

Suitable for:

-

diverse bread

-

Capacity:

-

1000-12000pcs/h

-

Final product:

-

Bread (length up to 50cm)

-

Advantage:

-

20 years experience

-

Material:

-

stainless steel

-

Application:

-

bread processing machine

-

Packing:

-

wooden case

-

Keywords:

-

bread production line

Quick Details

-

Brand Name:

-

WeiYi

-

Place of Origin:

-

China

-

Voltage:

-

380v

-

Power:

-

13kw

-

Dimension(L*W*H):

-

12700*1580*1500mm

-

Weight:

-

2500 KG

-

Machinery Function:

-

Baguette, Rye bread, Pita Bread, Focaccia, Ciabatta, White bread, Multigrain bread, Bagel, Brioche, Whole wheat bread, Bread roll, Bun, Challah

-

Output product name:

-

Diverse Bread

-

Product name:

-

bread production line

-

Usage:

-

bread manufacturing machines

-

Suitable for:

-

diverse bread

-

Capacity:

-

1000-12000pcs/h

-

Final product:

-

Bread (length up to 50cm)

-

Advantage:

-

20 years experience

-

Material:

-

stainless steel

-

Application:

-

bread processing machine

-

Packing:

-

wooden case

-

Keywords:

-

bread production line

Products Description

bread production line bakery machinery for bread making automatic bread slicer machine for bakery

Easy to Use

The whole machine is equipped with touch screen, photoelectric control, computer storage data, simple operation and high degree of automation.

Stable Performance

Using international brand electrical components, the performance is stable and reliable.

Flexible Configuration

Modular design of the unit, various collocation methods, and diversified production. Models developed according to customer needs.

The Finished Product Tastes Good

The surface of the dough is smooth and does not damage the dough, and the baked product has a fine and uniform organization and good taste.

Flexible Control

The thickness, forming and cutting size of the noodles can be adjusted, and the operation is convenient.

Advantage

High output, small footprint and less labor.

Welcome to Inquiry, Best Solution for You.

Final Products

Welcome to Inquiry, Best Solution for You.

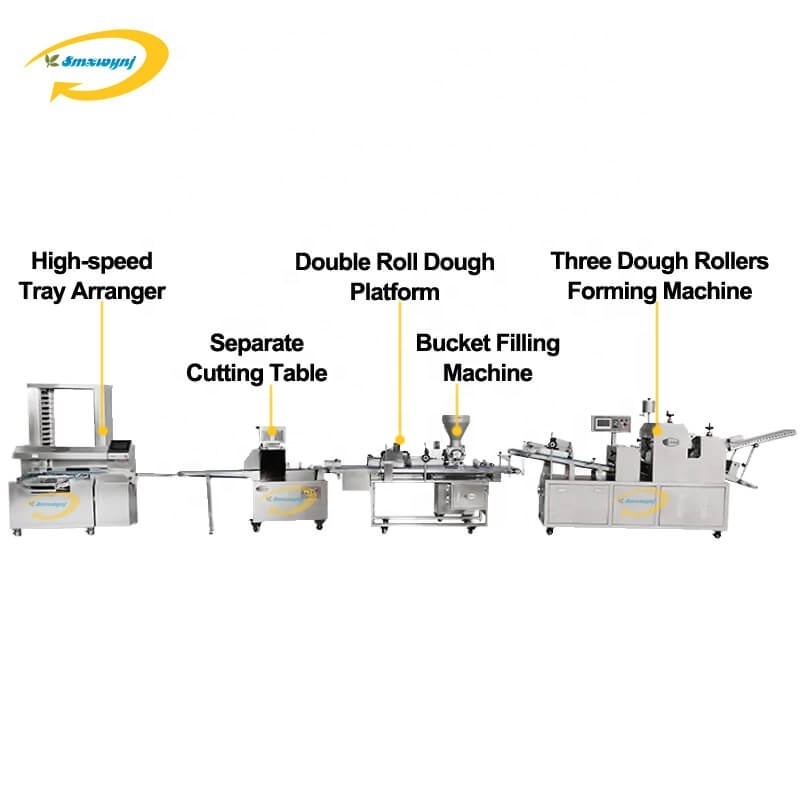

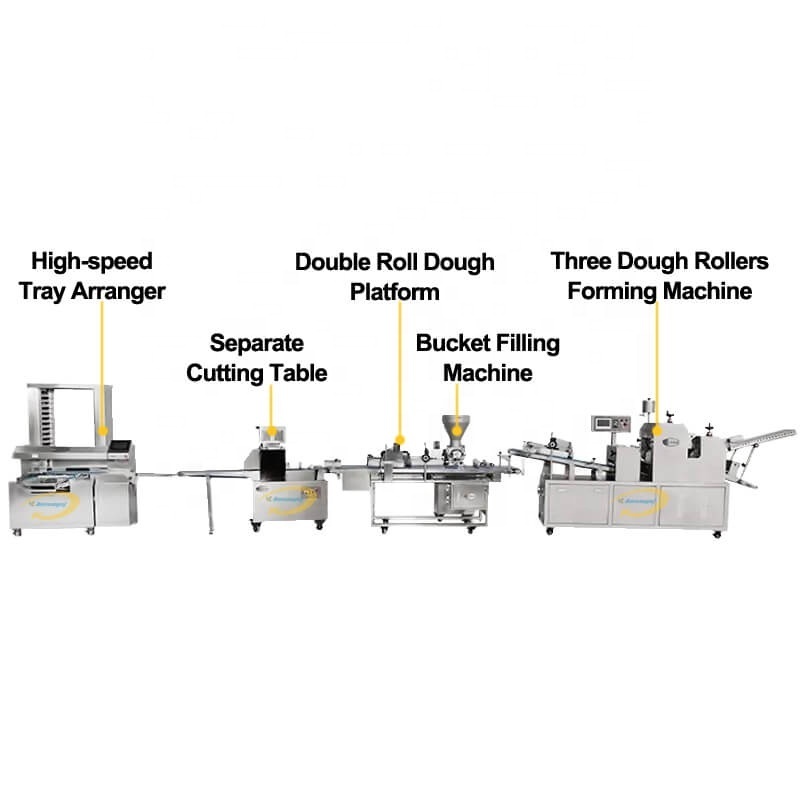

Details Images

Three Dough Rollers Forming Machine

The first choice is to put the reconciled dough into the three-stage rolling machine for rolling and stretching, so that the dough is more shiny and the quality is more stable;

Each rolling roller has a thickness adjustment device to set the thickness of the dough to increase or decrease the weight of the product;

The speed of the dough is controlled by the electric eye between the multi-roller, the pair of rollers and the thinning device, so that the dough will not be broken or blocked due to the fast conveying speed of the main machine; after the last pressing wheel of the main machine, the dough will fall on the main machine. on the conveyor belt.

Bucket Filling Machine

SLJX series automatic filling machine is suitable for filling meat, vegetables, bean paste, five kernel filling, sugar noodle filling, chocolate, potato and other fillings.

Double Roll Rough Platform

The double-rolled/multi-rolled platform can roll multiple lines at the same time, which is suitable for mass production and processing.

Separate Cutting Table

After filling, roll the dough into a column through the rolling wheel and auxiliary rolling wheel; open the separate cutting table, set the cutting length to determine the length and weight of the product; suitable for French bread, silk roll bread, brushed bread, toast , Caterpillar, Qiaokou Crisp, knife-cut steamed bread and other products segmented and divided.

High-speed Tray Arranger

It is suitable for automatic arranging of various moon cakes, breads, pastries, midpoints, steamed buns, steamed buns and other products. Parameters can be set according to customer needs. The products are arranged in an orderly manner.

Related Products

Packing & Delivery

Contact Us

【 If you want to get the latest prices, please click on "

Send

" below to leave us a message. 】

↓ ↓ ↓

Hot Searches