- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Language Speaking:

-

English, Spanish, etc.

-

Keyword:

-

Duct Air cooler Mould

-

Mould Material:

-

Steel

-

Steel Type:

-

P20

-

Mould base:

-

C50

-

Cavity:

-

Single

-

Runner:

-

Hot Runner

-

Mould life:

-

300,000shots

-

Design software:

-

UG, Pro/E, Auto CAD, Solidwork, etc.

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoxu

-

Model Number:

-

Customized

-

Language Speaking:

-

English, Spanish, etc.

-

Keyword:

-

Duct Air cooler Mould

-

Mould Material:

-

Steel

-

Steel Type:

-

P20

-

Mould base:

-

C50

-

Cavity:

-

Single

-

Runner:

-

Hot Runner

-

Mould life:

-

300,000shots

-

Design software:

-

UG, Pro/E, Auto CAD, Solidwork, etc.

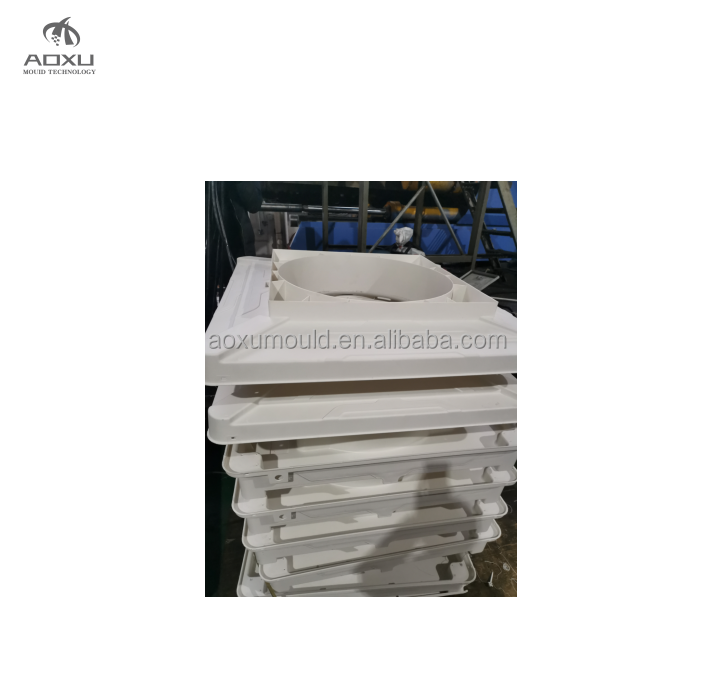

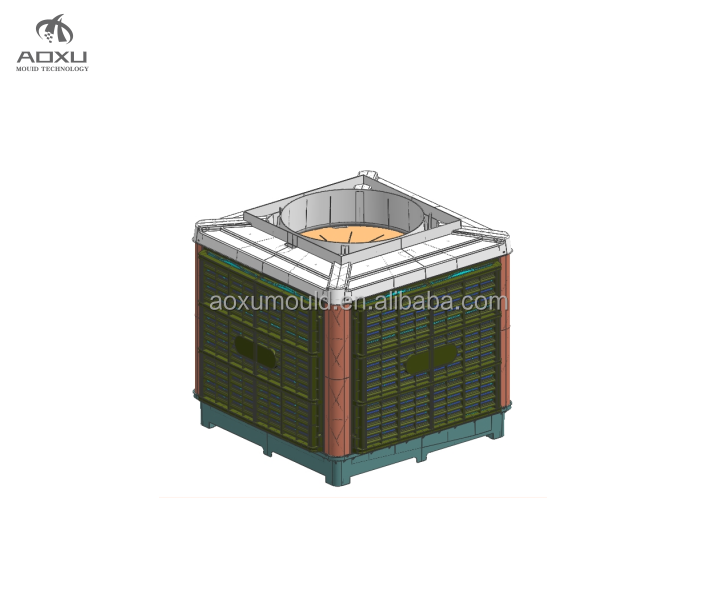

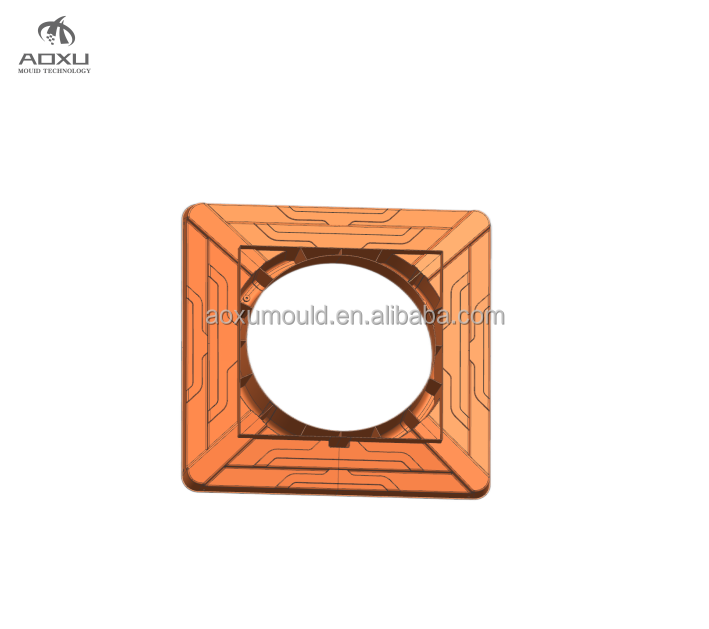

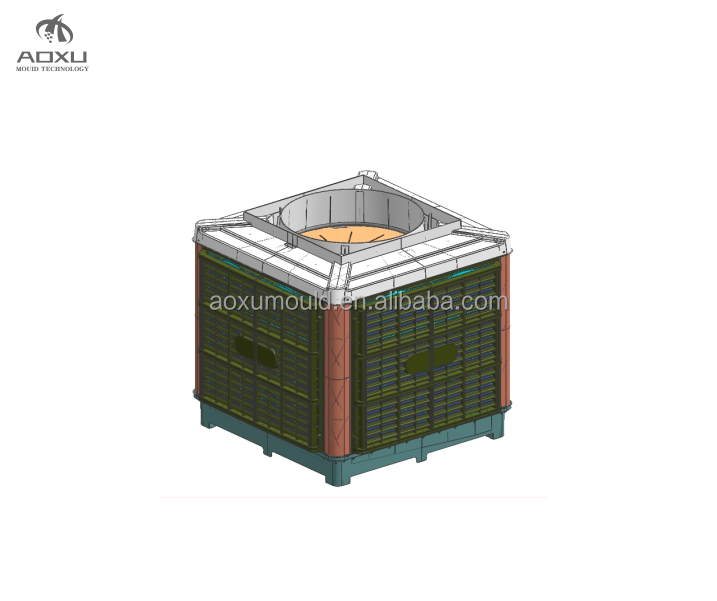

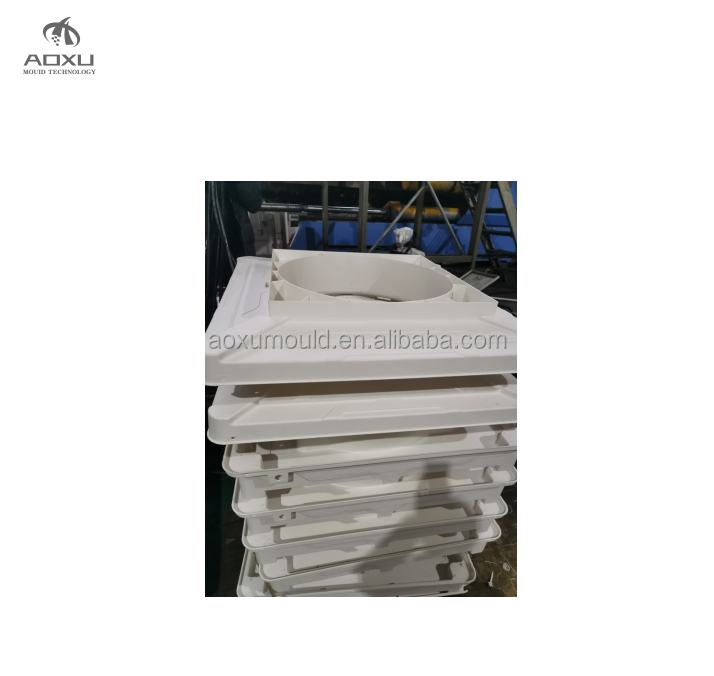

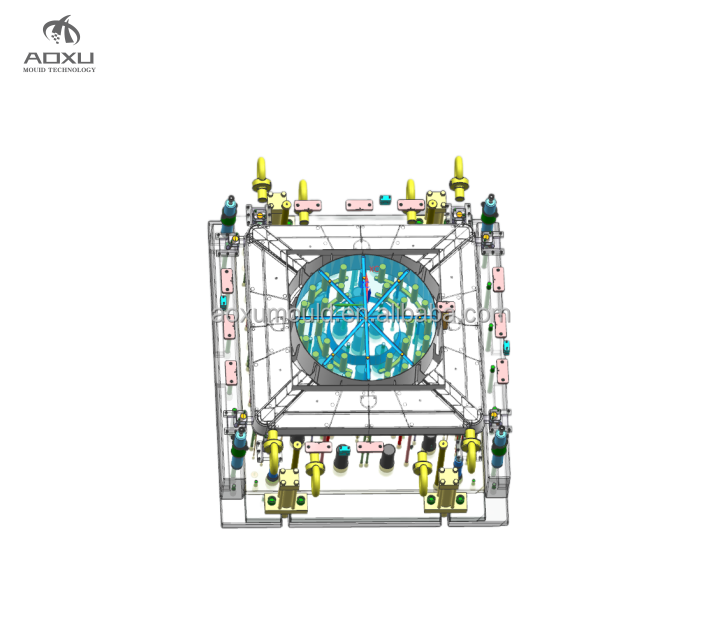

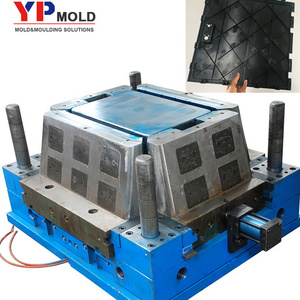

Plastic Injection Top Discharge Duct Air cooler Mould

We produce quality Duct Air cooler Moulds!

Our advantages of the mould have long shelf life, stable quality, high precision, and reasonable design.

Welcome to us have a visit(Leila Mob/WhatsApp/Wechat:+86 13606826958)!

Mould material: S50C, S60C, P20, 718H, 2738, H13, 2344, etc.

Information to quote: 2D,3D,samples or pictures of multiple points of view with dimensions.

Leadtime for mould: 30--60days, on basis of the difficulty level.

Service life : 500-1000 thousand times.

Cavity number of mold: 1 cavity, Multiple cavity or one Duct Air cooler Mould with different products.

Surface treatment: Mirror polish, Matte or textured surface.

Main process: Milling, grinding, CNC, EDM, wire-electrode cutting, carved, electrospark, lathe, etc.

Software: SolidWorks, UG,CAD(IGS,X-T,STP),PDF

Mold design time: Within 3 days(generally)

Mould testing: All of the moulds can be well tested before the shipments. Videos for testing the moulds are available according to clients’ requirements.

Good packages: In strong wooden case to avoid any damages during the long transportation.