Edge part of the speed can be adjusted, feeding belt can also be adjusted, according to their own proficiency to adjust,and the temperature can be controledIt can realize gluing while delivering tape, saving time, saving labor

and making more effective use of glue

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4500*900*1500

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

13m/min

-

Name:

-

GD-7200

-

Color:

-

Customized Making

-

Certification:

-

CE ISO

-

Edge thickness:

-

3-8 mm

-

Size:

-

customized

-

total power:

-

10.63kw

-

Air pressure:

-

0.9MPA

-

Machine weight:

-

2200KG

-

Machine size:

-

4500*900*1500mm

-

Mini work Panel Length:

-

>120 Mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

grandio

-

Voltage:

-

380/220v

-

Dimension(L*W*H):

-

4500*900*1500

-

Power (kW):

-

7.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

13m/min

-

Name:

-

GD-7200

-

Color:

-

Customized Making

-

Certification:

-

CE ISO

-

Edge thickness:

-

3-8 mm

-

Size:

-

customized

-

total power:

-

10.63kw

-

Air pressure:

-

0.9MPA

-

Machine weight:

-

2200KG

-

Machine size:

-

4500*900*1500mm

-

Mini work Panel Length:

-

>120 Mm

Product Description

Brief introduction

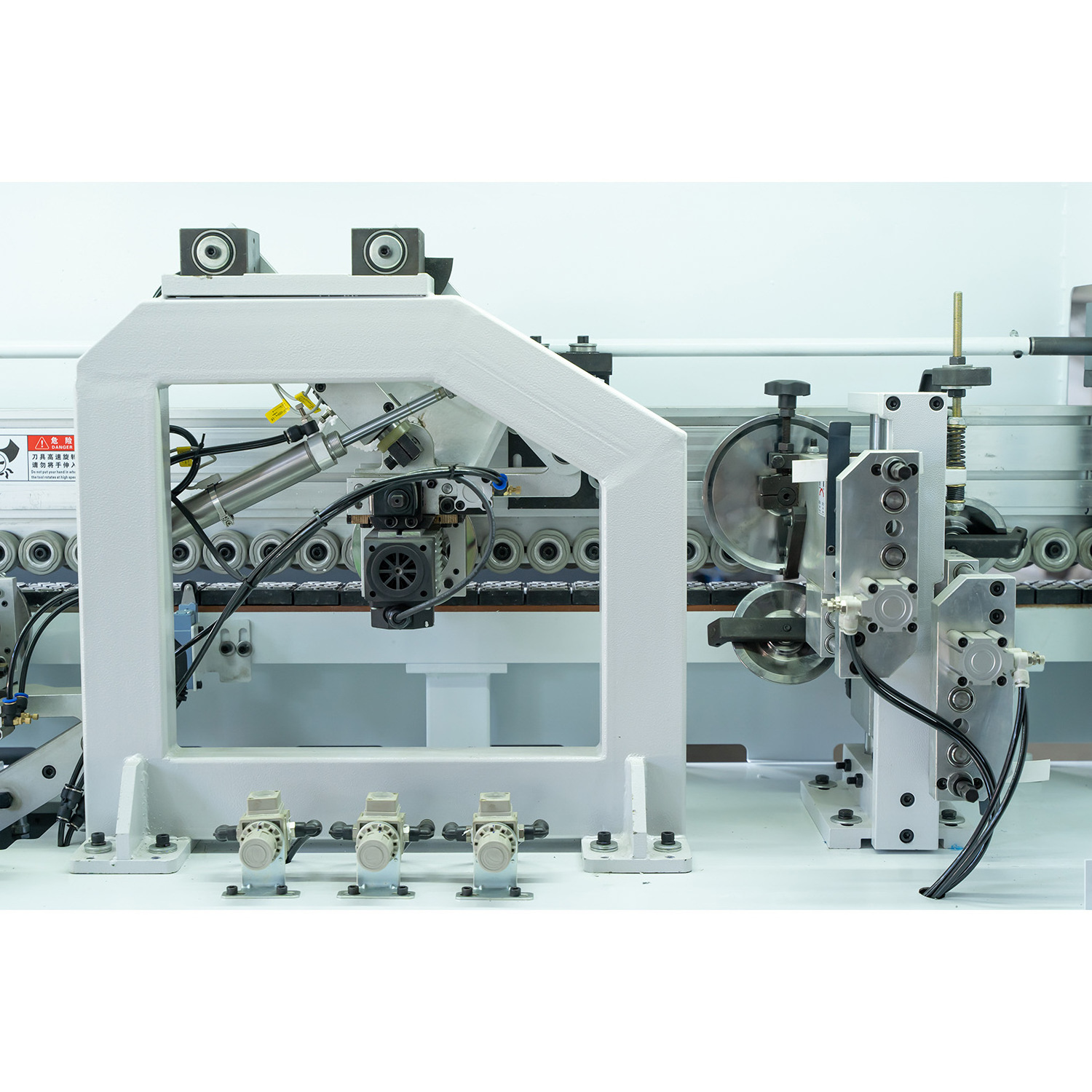

1.The edge banding machine adopts imported high-motor, it is high precision, lower noise,long life,processing stability.

2.Adopt imported frequency converter,action is sensitive and reliable and with good stability.

3.The function including 8 function:premilling, preheating pressing ,gluing,end cutting,rough trimming,fine trimming,corner , rounding, scraping,buffing.

1.The edge banding machine adopts imported high-motor, it is high precision, lower noise,long life,processing stability.

2.Adopt imported frequency converter,action is sensitive and reliable and with good stability.

3.The function including 8 function:premilling, preheating pressing ,gluing,end cutting,rough trimming,fine trimming,corner , rounding, scraping,buffing.

4.Machine frame: Welding frame adopts national standard 50 * 90 * 5mm rectangular pipe square tube and bottom 40 * 80 * 5 channel steel welded frame structure, pre-milled table of heavy-duty gantry milling machine to ensure the flatness of the equipment and the whole machine plastic appearance Beautiful and not rusty.

5.The beams are all 18mm thick high-quality high-strength ship plates. Sheet metal shells are 1.8-6mm thick cold plates.

6.There are feed plates and discharge plates on the front and back of the equipment to ensure the smooth operation of the board.

It is more convenient to not touch the material.

|

Model

|

GD-7200

|

|

Panel Feed Speed(m/min)

|

25m/min

|

|

Edge Thickness

|

0.4-3mm

|

|

Edge Width

|

15-55mm

|

|

Edge banding height

|

12-60mm

|

|

Panel thickness

|

8-30mm

|

|

Mini work Panel Width

|

> 80mm

|

|

Mini work Panel Length

|

>120 Mm

|

|

Heating power of plastic box

|

1.5kw

|

|

Plate preheating power

|

0.3KW

|

|

End cutting motor power

|

0.55kw * 2 1200r / min200HZ

|

|

Transmission motor power

|

2.2KW

|

|

Polishing motor power

|

0.2kw*2 1400r / min 300Hz

|

|

Fine trimming motor power

|

0.75kw*2 1800r / min 300Hz

|

|

Total power

|

10kw

|

|

Air pressure

|

0.9MPA

|

|

Machine weight

|

1500KG

|

|

Machine size

|

7200*1000*1800mm

|

Detailed Images

PLC Control system touch screen

Intelligent operation panel, simple operation, with fault detection.

Corner Rounding

Can shaped the panel then looks more beautiful. The function is a necessary step for cabinet door

Scraping

Used to scrape the extra glue, to make the edges more smoother. It is equipped with dust collector pips. Upper and lower radius scraper for the processing of 2 mm plastic edge material.

Rough Fine trimming

The roughing tool is a 15 ° flat tool with 40-50 thread allowance for finishing. The automatic tracking by film and high-frequency high-speed motor are used to realize fast cutting.

There are two counter rotating shape cutters and control by independent air cylinders, allow milling front edge and back edge without tear out. Ensure right angled and chip free work piece edges.

It is composed of front endtrimming and back end trimming. It is controlled byTaiwan Yadeke solenoid valve,1t has a unique function of endtrimming and plate collisionprotection. It iscut off by a special saw blade to enhancethe stability of end trimming.

The cleaning can clean the extra glues again. And 4 cloth wheels to polish the dust of the edging, to make it more clean and more beauty. Upper and lower buffing unit ensures a perfect finish on the edge radius and removes any color irregularities.

Sample

Certificate

Our Services

1.1 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

Packing&Shipping

Company Introduction

Shandong Grandio CNC

Equipment Co., Ltd is an innovative enterprise engaged in research and development, production, sales and good after- sales service. The company's main products include Panel furniture CNC cutting machine, Woodworking CNC Machining Center, CNC router, Multi-head cylinder CNC engraving machine, Styrofoam CNC router, 3D scanner, Vacuum membrane press machine, Vacuum forming machine, Laser engraving and cutting machine, etc. Products applied to the panel furniture, European furniture,solid wood furniture, advertising, stone, building decoration, handicrafts, mold making, staircases column, PCB printing,automotive industry, packaging industry, shipbuilding, wood manufacturing, watches and clocks, accessories, seals and other industries.

After nearly 10 years of development, the company has a perfect technical team, clear labor division, ensuring the high quality products sent to the whole country, to the world.

We offer our customers best solutions, including product design,installation, training, aftersales service, etc. With the market development demand as the orientation, we stick to innovate and improve technology continuously, to the peak of CNC industry is our relentless drive.

After nearly 10 years of development, the company has a perfect technical team, clear labor division, ensuring the high quality products sent to the whole country, to the world.

We offer our customers best solutions, including product design,installation, training, aftersales service, etc. With the market development demand as the orientation, we stick to innovate and improve technology continuously, to the peak of CNC industry is our relentless drive.

FAQ

1. who are we?

We are based in Shandong, China, start from 2016,sell to Africa(10.00%),Domestic Market(10.00%),Western Europe(8.00%),South Asia(8.00%),Mid East(8.00%),Southern Europe(8.00%),South America(8.00%),Southeast Asia(8.00%),Northern Europe(8.00%),Eastern Asia(5.00%),Oceania(5.00%),North America(5.00%),Eastern Europe(5.00%),Central America(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

woodworking cnc machine,CNC router,Vacuum membrane press machine,3D scanner,laser cutting and engraving machine

4. why should you buy from us not from other suppliers?

jinan Grandio CNC Equipment Co., Ltd is an innovative enterprise engaged in research and development, production, sales and good after- sales service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean, Hindi,Italian

We are based in Shandong, China, start from 2016,sell to Africa(10.00%),Domestic Market(10.00%),Western Europe(8.00%),South Asia(8.00%),Mid East(8.00%),Southern Europe(8.00%),South America(8.00%),Southeast Asia(8.00%),Northern Europe(8.00%),Eastern Asia(5.00%),Oceania(5.00%),North America(5.00%),Eastern Europe(5.00%),Central America(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

woodworking cnc machine,CNC router,Vacuum membrane press machine,3D scanner,laser cutting and engraving machine

4. why should you buy from us not from other suppliers?

jinan Grandio CNC Equipment Co., Ltd is an innovative enterprise engaged in research and development, production, sales and good after- sales service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean, Hindi,Italian

Hot Searches