- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.67KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2200*1350*1150mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

blending tank manufacturer / mixing boiler / vessel

-

Material:

-

SUS304

-

Product name:

-

Pasteurized milk making machine mixing machine

-

Capacity:

-

500L-10000L

-

Sterilizing system:

-

UHT tubular sterilizer

-

Control:

-

Automatic control

-

Cleaning:

-

CIP system

-

Feature:

-

Vertical Tank

-

Processing:

-

Mixing+Pasteurizing+freezing+Homogenizing

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Voltage:

-

380V 3PH 50Hz

-

Power:

-

3.67KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2200*1350*1150mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

blending tank manufacturer / mixing boiler / vessel

-

Material:

-

SUS304

-

Product name:

-

Pasteurized milk making machine mixing machine

-

Capacity:

-

500L-10000L

-

Sterilizing system:

-

UHT tubular sterilizer

-

Control:

-

Automatic control

-

Cleaning:

-

CIP system

-

Feature:

-

Vertical Tank

-

Processing:

-

Mixing+Pasteurizing+freezing+Homogenizing

GRANDEE MACHINE

is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Products Description

Acid-alkali tank

Tank material: SUS304, Effective volume:5000L. Support form: vertical type, 4 legs, normal pressure container. Taper sealing head up and down. Tank configuration:mouth of breath, hole, feeding hole, into the hot water, CIP cleaning mouth, etc. Tank configuration digital temperature meter, high and low liquid level gauge, temperature sensor interface, etc. Tank bottom have feed out hole. Polyester foam insulation, digital temperature controller and thermometer, holeφ400, liquid level gauge, in-wall 3mm, external 1.5MM, discharge on the upper feed side, discharge port 450MM above the ground, dimensions (mm) : φ1900*3200 Temperature sensor: PT100,4-20Am Electric conductivity: PT100,4-20Am Liquid level switch: SUS304 Diaphragm pump: SUS304,300L/H

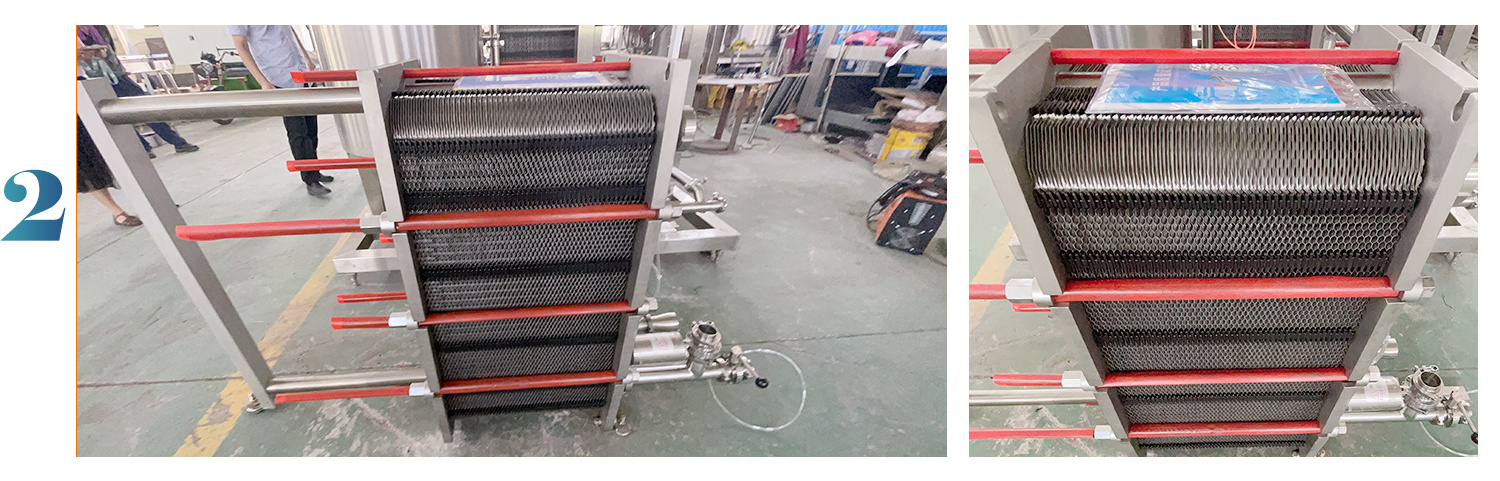

Plate heat excahnger

Plate heat exchanger is a kind of energy-saving equipment to realize the heat transfer between two or more kinds of fluids at different temperatures, which is to transfer the heat from the fluid with higher temperature to the fluid with lower temperature, so that the fluid temperature reaches the specified indicators of the process to meet the needs of the process conditions, and is also one of the main equipment to improve the energy utilization rate. It can be widely used in steel, power generation, non-ferrous metals, grease, chemical, petrochemical, shipbuilding, HVAC, refrigeration, pharmaceutical, dairy, beer, beverages, central heating and other fields.

The detachable plate heat exchanger is composed of metal heat exchange plate, front and rear baffle plate, sealant pad, guide rod, frame and so on. The adjacent plates and the sealant pad between them constitute a closed flow channel, and the hot and cold fluids flow through different flow channels and transfer heat through the plates under the guidance of the sealing pad to achieve the effect of heat exchange.

Area : 14㎡ Stainless steel 316L material plate, inlet and outlet φ51, A3 bracket, outer stainless steel, steam inlet and outlet φ51

The detachable plate heat exchanger is composed of metal heat exchange plate, front and rear baffle plate, sealant pad, guide rod, frame and so on. The adjacent plates and the sealant pad between them constitute a closed flow channel, and the hot and cold fluids flow through different flow channels and transfer heat through the plates under the guidance of the sealing pad to achieve the effect of heat exchange.

Area : 14㎡ Stainless steel 316L material plate, inlet and outlet φ51, A3 bracket, outer stainless steel, steam inlet and outlet φ51

Mixing tank

Tank material:SUS304,Effective volume:4000L. Support form: vertical type, 4 legs, normal pressure container. Taper sealing head up and down. Tank configuration:mouth of breath, hole, feeding hole, into the hot water, CIP cleaning mouth, etc.Top vertical mechanical mixing structure, stirring speed 56rpm, motor power 2.2kw. Paddle mixer. Tank configuration digital temperature meter,high and low liquid level gauge. Tank bottom have feed out hole.

Weighing module: SUS304, Temperature sensor:PT100,4-20Am Plate heat exchanger: Production capacity: 15 tons/hour. Material: SUS304, the frame is stainless steel, the heat exchange area is 16㎡.

Material pump: 10T/H SUS304, carbide mechanical seal, inlet and outlet φ51, H=24M;

Weighing module: SUS304, Temperature sensor:PT100,4-20Am Plate heat exchanger: Production capacity: 15 tons/hour. Material: SUS304, the frame is stainless steel, the heat exchange area is 16㎡.

Material pump: 10T/H SUS304, carbide mechanical seal, inlet and outlet φ51, H=24M;

CIP

Split semi-automatic control, acid tank 3000L , alkali tank 3000L ,hot water tank 3000L , plate heating, steam ratio adjustment and early control. Configuration: CIP process pump 20T/H, 36-meter head, PE concentrated acid and concentrated alkali barrels, American pneumatic diaphragm pump, acid and alkali addition part, stainless steel straight pipe, valves, pipe fittings, bracket pipe accessories, electrical control box, power cord, Signal lines, wiring pipes, and temperatures are automatically controlled.

Material SUS304, stainless steel shell, stainless steel filter, filtration area 0.3㎡, filtration precision: 120 mesh, including

conversion butterfly valve.

UHT

Model: INTOP-6, flow rate: 6T/H; material SUS304, feeding 55℃, sterilization 135℃/15S, homogenization 65-70℃, discharging 65℃, PID automatic control, Siemens, PLC, Schneider Electric. The hot water pump adopts the Nanfang Pump Industry brand; the steam flow regulating valve, steam pressure reducing valve, sanitary ball valve, medium ball valve, butterfly valve, and pneumatic butterfly valve are all made of top domestic brands; stainless steel frame, stainless steel pipe valve, distribution box, thermometer, Pressure gauge, etc., total power: 7.5KW Dimensions (mm): 6500*2500*2700

Homogenizer

Flow: 4T/H, rated pressure: 25Mpa, working pressure: 32Mpa, frequency conversion control, built-in control 1cabinet. Two-stage pressurization,dimensions L*W*H 2.3*1.4*1.6, power 37KW

Vacuum degasser

The function of the vacuum degasser is to remove air (oxygen) from the feed liquid, inhibit browning, oxidation of pigments, vitamins, fragrance components and other substances, and prevent quality degradation; remove suspended particulate gas attached to the feed liquid and inhibit particulates Float and maintain a good appearance; prevent foaming from affecting sterilization during canning and high-temperature sterilization; reduce corrosion to the inner wall of the container.

Remove air (oxygen) from the feed liquid, inhibit browning, oxidation of pigments, vitamins, fragrance components and other substances, and prevent quality degradation; remove suspended particulate gas attached to the feed liquid, inhibit the floating ofparticles, and maintain a good appearance; prevent Foaming during canning and high-temperature sterilization affects sterilization; reducing corrosion of the inner wall of the container.

Remove air (oxygen) from the feed liquid, inhibit browning, oxidation of pigments, vitamins, fragrance components and other substances, and prevent quality degradation; remove suspended particulate gas attached to the feed liquid, inhibit the floating ofparticles, and maintain a good appearance; prevent Foaming during canning and high-temperature sterilization affects sterilization; reducing corrosion of the inner wall of the container.

Sterile storage tank

Tank material: SUS304, effective volume: 4000L. Support form: vertical, 4 legs, normal pressure container: insulation tank, insulation layer thickness is not less than 50 mm, covered with stainless steel, thickness is not less than 2mm. Upper and lower tapered heads. Tank configuration: breathing port, manhole, feed port, CIP cleaning port, etc.

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

Turnkey Solution

Hot Searches