- Product Details

- {{item.text}}

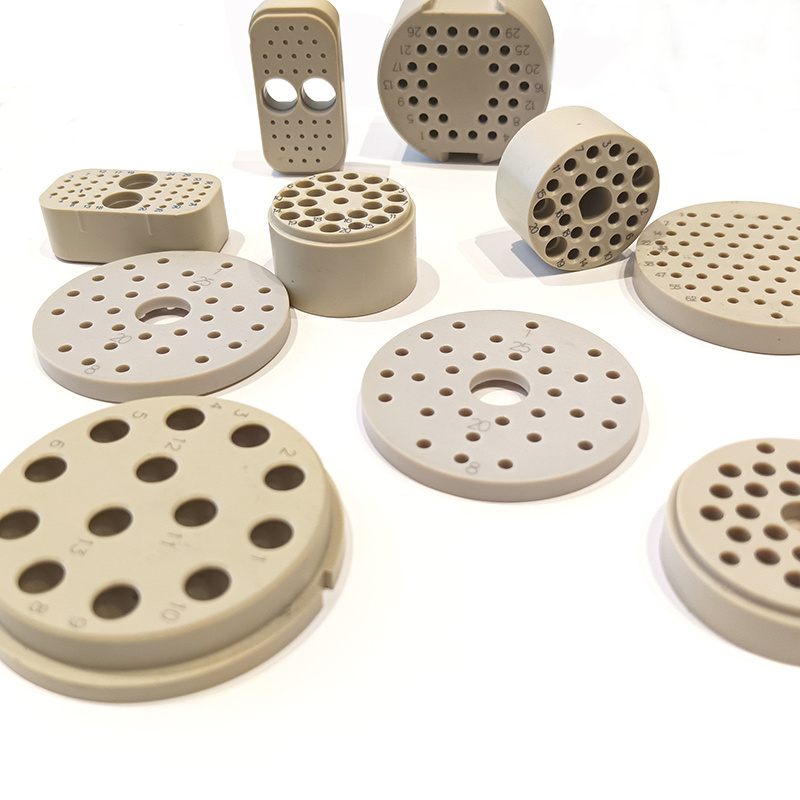

Quick Details

-

Model Number:

-

TECAPEEK CMF natural

-

Processing Type:

-

3/4/5 Axis CNC Machining

-

Material:

-

Plastic

-

Product name:

-

Custom Industrial Product

-

Color:

-

Customized Color

-

Logo:

-

Accept Customized Logo

Quick Details

-

Processing Service:

-

CNC machine processing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Ensinger

-

Model Number:

-

TECAPEEK CMF natural

-

Processing Type:

-

3/4/5 Axis CNC Machining

-

Material:

-

Plastic

-

Product name:

-

Custom Industrial Product

-

Color:

-

Customized Color

-

Logo:

-

Accept Customized Logo

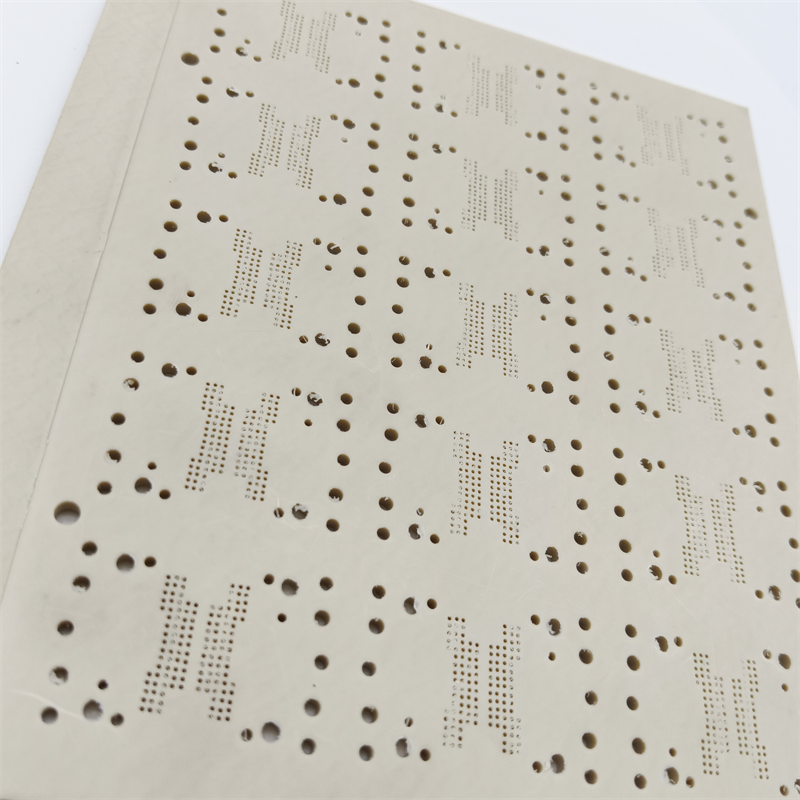

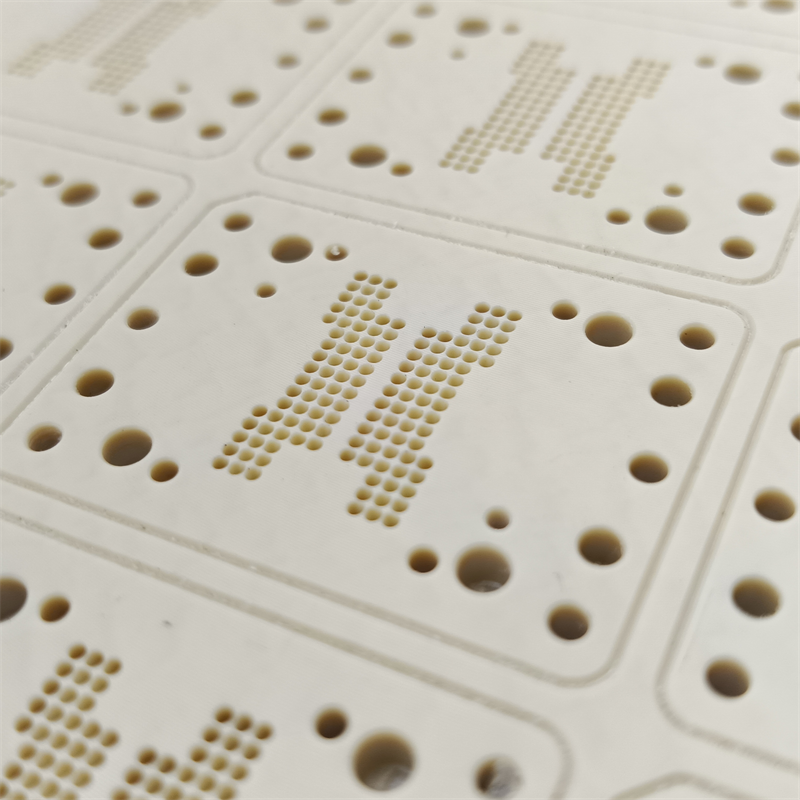

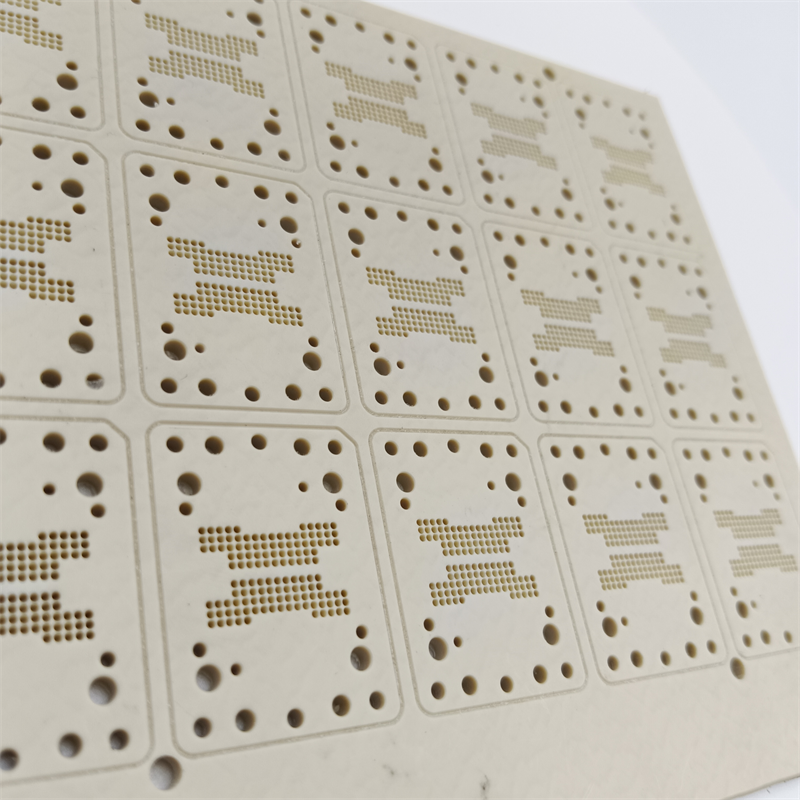

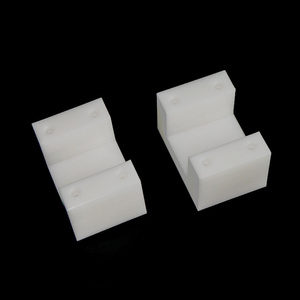

The color of pure Peek is generally pale yellow. Modified (carbon fiber, graphite) Peek is generally black. PEEK with ceramics is generally white. In addition, the PEEK with glass fiber is generally coffee.

PEEK product performance

| High temperature resistance |

Use 260 ° C for a long time and the instantaneous use temperature can reach 300 ° C |

| Anti -radiation | Use it to resist 1.1 × 10Gy γ -ray. |

| Flame retardant | Can reach UL standard 94V-0 level |

| Hydrolysis and steam resistance | It can be used for a long time in steam at 200 ~ 50 ° C |

| Non -toxicity | Can be used in food hygiene, medical device and other fields |

| Electrical insulation | At 10Hz, its dielectric constant in the room is only 3.2, and the dielectric loss is only 0.02 |

| Quotation |

According to your drawings (size, material, thickness, processing content, required process, etc.) |

| Plastic raw material |

PEEK/PEEK+GF30 or other materials(PI,PPSU,PAI,PBI,PEI,PPS, HDPE,PTFE,PVDF,PET..) |

| color | This color, black or ceramic white |

| Receive drawings | 3D (DXE.DWG), PDF, professional version/engineer |

|

Application field

|

Electronics industry, medical industry, home appliance industry, aerospace, shipbuilding industry, home supplies, cars

Industry, machinery industry, semiconductor industry, food processing, robotics industry, etc. |

Question 1. Can I only produce samples?

Answer 1. Yes

Question 2. What is the product accuracy of drawing processing?

Answer 2. Different

The equipment accuracy is different, generally between 0.05-0.1

Question 3. What processes do you have to process accessories?

Answer 3. Depending on different products, different processes, such as machine processing, extrusion, injection molding, etc.

Question 4. What is your processing equipment?

Answer 4. CNC processing center, CNC lathe, milling machine, carving machine, injection molding machine, extrusion machine, molding machine

Question 5. After the product is completed, can you help assemble?

Answer 5. No matter

Question 6. What certification or qualifications do you have?

Answer 6. Our company's certificates are: ISO, ROHS, product patent certificate, etc.

Question 7. Can injection molding products be treated on the surface? What are the surface treatment?

Answer 7. OK. Surface treatment: spray paint, silk print,

Electroplating, etc.