- Product Details

- {{item.text}}

Quick Details

-

Drilling Speed:

-

1200 ~ 1800 holes/Hour

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aituo Automation

-

Model Number:

-

AM20111

-

Voltage:

-

AC220V 50Hz

-

Dimension(L*W*H):

-

240*240*396MM

-

Power (kW):

-

300W

-

Weight (KG):

-

9 KG

-

Product name:

-

Round Hole Drilling Machine

-

Keyword:

-

Drilling Turning Machine

-

Application:

-

Plastic Processing

-

Machine type:

-

Drilling Equipment

-

Brand:

-

Aituo Automation

-

Series:

-

Round Hole Drilling

-

Model:

-

AM20111

-

Advantage:

-

Simple Structure

-

Material:

-

Aluminum Steel Stainless Steel

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

type:

-

EDM Drilling Machine

-

Max. Drilling Dia. (mm):

-

3 mm

-

Range of Spindle Speed(r.p.m):

-

100 - 12000 r.p.m

-

Drilling Speed:

-

1200 ~ 1800 holes/Hour

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aituo Automation

-

Model Number:

-

AM20111

-

Voltage:

-

AC220V 50Hz

-

Dimension(L*W*H):

-

240*240*396MM

-

Power (kW):

-

300W

-

Weight (KG):

-

9 KG

-

Product name:

-

Round Hole Drilling Machine

-

Keyword:

-

Drilling Turning Machine

-

Application:

-

Plastic Processing

-

Machine type:

-

Drilling Equipment

-

Brand:

-

Aituo Automation

-

Series:

-

Round Hole Drilling

-

Model:

-

AM20111

-

Advantage:

-

Simple Structure

-

Material:

-

Aluminum Steel Stainless Steel

-

After-sales Service Provided:

-

Video Technical Support

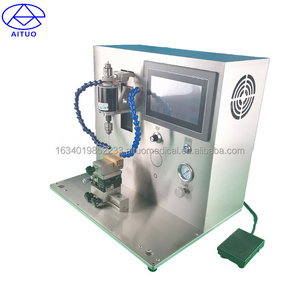

high quality medical catheter eye/hole drilling machine

Products Description

This device is mainly used for punching holes in medical plastic catheters. It uses manual loading and consists of two

workstations: a fine-tuning platform and a Z-axis assembly. The device is compact in structure, and the drill chuck uses a

three-way active drill chuck that can accommodate hollow drills from 0.3 to 4mm in diameter. It is equipped with a reset ejector structure that ejects waste from the drill when it is reset. The punching direction and position can be freely adjusted.

workstations: a fine-tuning platform and a Z-axis assembly. The device is compact in structure, and the drill chuck uses a

three-way active drill chuck that can accommodate hollow drills from 0.3 to 4mm in diameter. It is equipped with a reset ejector structure that ejects waste from the drill when it is reset. The punching direction and position can be freely adjusted.

Specifications

|

Product

|

AM20111 Round Hole Drilling Machine

|

|

Power supply

|

AC 220V, 50Hz

|

|

Ambient temperature

|

-20℃+50℃

|

|

Working pressure

|

0.5-0.8Mpa

|

|

Fixture size

|

L40*W10*H15mm

|

|

Tool size

|

L25*W10*H3.8mm

|

|

Cylinder pushing force

|

Max 1000N

|

|

Tube diameter

|

4Fr-10Fr

|

|

Applicable materials

|

PVC, PU, TPU, HDPE, LDPE, PP, PA, PEBAX, etc

|

|

9Weight

|

9kg

|

|

Size

|

240*240*396mm

|

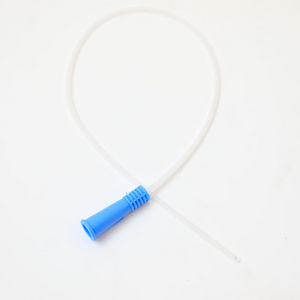

Cutting Tool

1.Application Material:

PVC, PU, TPU, HDPE, LDPE, PP, PA, PEBAX, etc

2.

Application Product:

Central venous catheter, dialysis catheter, catheter sheath,dilation catheter, PICC catheter, drainage catheter, tracheal intubation, urinary catheter, indwelling needle, etc.

About us

Aituo

Company is a leading manufacturer of catheter processing machines. We specialize in the design, development, and production for catheter processing machines. Our company was founded in 2011 with a commitment to providing our customers with the highest quality products and services. We are a team of experienced engineers and technicians who are passionate about our work. We are committed to providing our customers with innovative solutions that meet their specific needs.

Our Products

We offer a wide range of catheter processing machines including:

Catheter hot tip forming machine

Catheter hot tip melting machine

Catheter hole drilling machine

Catheter hole punching machine

Catheter hot shape forming machine

Catheter flaring machine

Catheter extrusion machine

Our Services

We offer a variety of services to our customers, including:

*Custom design and development

*Technical support

*Training

We are committed to working with our customers to ensure that they receive the machines and services they need to meet their specific needs.

Our Commitment to Quality

We are committed to providing our customers with the highest quality products and services. We have a rigorous quality control program in place to ensure that our products meet our high standards. We are also committed to environmental sustainability. We use environmentally friendly materials and processes in the manufacture of our machines.

Our Mission

Our mission is to be the leading provider of catheter secondary processed machines. We are committed to providing our customers with innovative solutions that meet their specific needs.

We offer a wide range of catheter processing machines including:

Catheter hot tip forming machine

Catheter hot tip melting machine

Catheter hole drilling machine

Catheter hole punching machine

Catheter hot shape forming machine

Catheter flaring machine

Catheter extrusion machine

Our Services

We offer a variety of services to our customers, including:

*Custom design and development

*Technical support

*Training

We are committed to working with our customers to ensure that they receive the machines and services they need to meet their specific needs.

Our Commitment to Quality

We are committed to providing our customers with the highest quality products and services. We have a rigorous quality control program in place to ensure that our products meet our high standards. We are also committed to environmental sustainability. We use environmentally friendly materials and processes in the manufacture of our machines.

Our Mission

Our mission is to be the leading provider of catheter secondary processed machines. We are committed to providing our customers with innovative solutions that meet their specific needs.

Packaging & Shipping

All machines will be packed with plywood, covered with steel tie on the surface in order to avoid damaging during delivery.

Before the shipment, we will provide you some pictures of the goods and the package.

Shipping

The machines will be shipped out by Express delivery, by Air, by Sea. Or if you have your own shipment forwarder, you also can ask them to arrange the shipment.

(1) By DHL, FedEx, UPS,etc (Door to Door Service)around 5-7days to arrive.

(2) By Air, to your airport (Door to Airport Service), around 3-5 days to arrive.

(3) By Sea, to the seaport (Door to Seaport service), around 30 days to arrive.

Exhibition

Customer Photos

FAQ

1. Why choose Shenzhen Aituo?

We are a real machine manufacturer. We have been specializing in automation equipment for more than ten years with a strong team of engineers. We can provide you with the most professional pre-sales technical guidance and after-sales service.

2. How long is the machine warranty?

The machine has a one-year warranty, except for consumables. And we provide lifetime technical support.

3. Is the machine easy to operate? Is it convenient for maintenance?

The machine is simple to operate and easy to use. And we will also provide the machine manual after you bought it. And the machine is semi-automatic and easy to maintain.

4. After receiving the machine, do we still need to assemble or debug the machine?

No, we sell the complete machine. You don't need to assemble the machine. Before shipment, our engineer will debug everything well. You can use it immediately after you receive the machine.

5. Can your company provide free on-site training?

Yes, after you place the order, you can ask your engineers come to learn how to operate the machine in our factory.

6. Can the machine be customized?

Yes, our machines can be customized according to your requirements

7. What is the lead time?

After receiving your payment, the machine will be finished within 15-30 days

2. How long is the machine warranty?

The machine has a one-year warranty, except for consumables. And we provide lifetime technical support.

3. Is the machine easy to operate? Is it convenient for maintenance?

The machine is simple to operate and easy to use. And we will also provide the machine manual after you bought it. And the machine is semi-automatic and easy to maintain.

4. After receiving the machine, do we still need to assemble or debug the machine?

No, we sell the complete machine. You don't need to assemble the machine. Before shipment, our engineer will debug everything well. You can use it immediately after you receive the machine.

5. Can your company provide free on-site training?

Yes, after you place the order, you can ask your engineers come to learn how to operate the machine in our factory.

6. Can the machine be customized?

Yes, our machines can be customized according to your requirements

7. What is the lead time?

After receiving your payment, the machine will be finished within 15-30 days

Hot Searches