- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380 v

-

Dimension(L*W*H):

-

1800

-

Weight:

-

1000 KG

-

Product name:

-

Drum Separating Machine, Copper Ore Magnetic Separator Magnetite

-

Roller Diameter:

-

600 mm

-

Roller Length:

-

1800 mm

-

magnetic field intensity:

-

1500oe

-

Capacity:

-

15-25 t/h

-

power:

-

2.2 kw

-

Application:

-

processing fine

-

Keywords:

-

magnetic separator manufacturer, magnetic separator for powder

-

Installation:

-

Under Guidance

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Production Capacity:

-

15-25 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BAICHY

-

Voltage:

-

380 v

-

Dimension(L*W*H):

-

1800

-

Weight:

-

1000 KG

-

Product name:

-

Drum Separating Machine, Copper Ore Magnetic Separator Magnetite

-

Roller Diameter:

-

600 mm

-

Roller Length:

-

1800 mm

-

magnetic field intensity:

-

1500oe

-

Capacity:

-

15-25 t/h

-

power:

-

2.2 kw

-

Application:

-

processing fine

-

Keywords:

-

magnetic separator manufacturer, magnetic separator for powder

-

Installation:

-

Under Guidance

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Mineral Iron Ore Magnetic Separator Price, Tin Ore Magnetic Drum Separating Machines, Copper Ore Magnetic Separator Magnetite

magnetic separator for manganese ore

magnetic separator for manganese ore are devices that are primarily used for eliminating tramp iron from ores and for removing contaminating materials that can damage equipment. There are mainly two kinds of magnetic separators produced by our factory. They are wet magnetic separator, magnetic drum separator and magnetic separator machine. In concentration processes, the magnetic separator for manganese ore machine is commonly used for sorting various types of metals. Similarly, in case of weak magnetic minerals such as hematite, limonite and garnet, they can be separated from the non-magnetic substances by the use of high- intensity separators

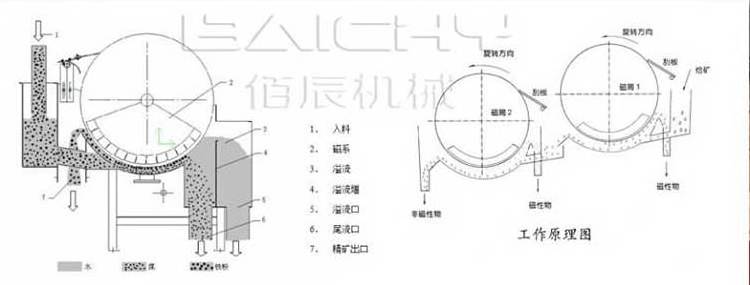

Working Principle of magnetic separator for manganese ore

The pulp flows into cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or magnet chain which is influenced by the magnetic force inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

magnetic separator for manganese ore is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite, pyrrhotite, calcined ore and ilmenite and can also be used for removing iron from the materials such as coal, non-metal ore and building material.

Process Chart of magnetic separator for manganese ore

Short magnetic circuit; little magnetic flux leakage; high magnetic intensity; Low energy consumption; fine beneficiating results; simple structure and easy maintenance. Magnetic Separator is used to separate magnetite, hematite, limonite, pyrrhotite, ilmenite smaller than 3 mm in wet way. It is also used to separate iron in coal, nonmetallic ore, construction industry, etc. We can provide magnetic separators of forward flow, semi counter flow and counter flow types according to customers' request.

| Model | Magnetic field intensity (oe) | Capacity (t/h) | Power (kw) | Weight (kg) |

|---|---|---|---|---|

| CTB600×900 | 1450 | 8.0-15 | 1.1 | 910 |

| CTB600×1800 | 1500 | 15-25 | 2.2 | 1340 |

| CTB750×1800 | 1550 | 30-45 | 3 | 2050 |

| CTB900×1800 | 1650 | 35-60 | 4 | 3000 |

| CTB1050×2400 | 1650 | 60-95 | 5.5 | 5020 |

| CTB1200×3000 | 1650 | 80-150 | 7.5 | 7800 |

| CTB1500×3000 | 1650 | 120-200 | 11 | 9600 |

|

Jaw Crusher

|

Impact Crusher | Cone Crusher |

|

Grinding Mill

|

Baill Mill | Mobile Crusher Plant |

20 national service mileage:

Service mileage for local customers to provide equipment installation, commissioning and after-sales service

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.