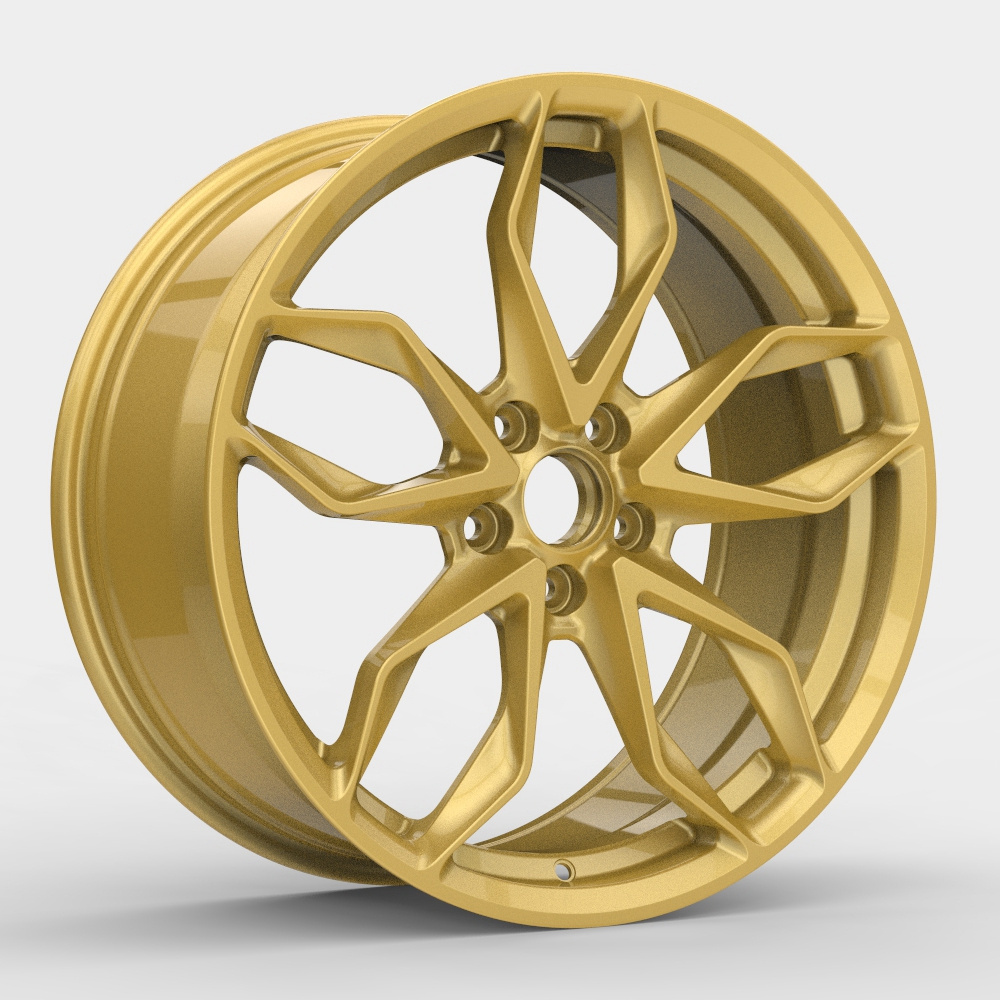

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

3 Years, 3 years 100,000km

-

Model Number:

-

ASW038

-

Color:

-

customizable

-

Meterial:

-

Aluminum 6061-T6

-

Package:

-

Carton Box

Quick Details

-

Finishing:

-

customizable

-

Width:

-

8.5/9.5 Inch

-

Place of Origin:

-

Zhejiang, China

-

Warranty:

-

3 Years, 3 years 100,000km

-

Model Number:

-

ASW038

-

Color:

-

customizable

-

Meterial:

-

Aluminum 6061-T6

-

Package:

-

Carton Box

Product Description

|

Difference of Forged and Casted Wheels

|

|

|

||

|

Item

|

Forged

|

Casted

|

||

|

Aluminum TYPE

|

6061-T6

|

A365-T6

|

||

|

MECHANICAL PROPERTIES

|

TENSILE STRENGTH>330MPA

YIELD STRENGTH>300MPA

ELONGATION RATE>12%

|

TENSILE STRENGTH>260MPAYIELD STRENGTH>180MPA

ELONGATION RATE>7% |

||

|

FEATURES

|

1. Forging aluminum alloy material because there is no solid-liquid-solid transition of the material, the inseparable corripontes such as segregation, loosening, and oxide inclusions are avoided.

2. after the forging process deforms the billet forging, the material structure becomes denser, so the mechanical properties of the material are higher.

3.The mechanical properties of all parts of the forging hub are the same

|

1.Due to casting molding reasons, castings have different mechanical properties at different locations due to different cooling conditions.

2.Spokes generally have an elongation of about 4%, while rims have an elongation of about 10%. therefore, the aluminum wheel produced by the casting process can only be used in the area of cars.

|

||

|

Meets the needs of flat tires

|

The mechanical strength of the aluminum alloy wheel produced by the forging process is more suitable for the flat tire re quirements of the vehicle

|

Unable to meet tire flatness requirements

|

||

Specification

|

Place of Origin

|

China

|

|

|

Zhejiang

|

|

Warranty

|

36 months

|

|

Aluminum

|

6061-T6

|

|

Finishing

|

customizable

|

Equipment and quality inspection

As is clearly seen from the graph, forged rims have very high material thickness. As a result, forged aluminum wheels achieve

a significantly higher strength at low wall thickness, which in turn is demonstrated in lower weight of the end products as compared to cast rims.

In addition to this, the surface condition is of higher quality than that of a "cast rim" as hardly any air of material inclusions occur.

Hot Searches