- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

450

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK MACHINE

-

Dimension(L*W*H):

-

920*840*2600mm

-

Material:

-

SUS304

-

Packing speed:

-

40bags/min

-

Automaticity:

-

full automatic

-

Control:

-

PLC Control

-

Bag type:

-

triangle tea bag packing machine

-

Measuing scope:

-

1-7g

-

Bag size:

-

L40-80mm W60-80mm

-

Machine name:

-

Nylon triangle tea bag packing machine

-

Dimension:

-

920(L)*840(W)*2600(H)mm

-

Weight:

-

450kg

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Bags, Film, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

450

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK MACHINE

-

Dimension(L*W*H):

-

920*840*2600mm

-

Material:

-

SUS304

-

Packing speed:

-

40bags/min

-

Automaticity:

-

full automatic

-

Control:

-

PLC Control

-

Bag type:

-

triangle tea bag packing machine

-

Measuing scope:

-

1-7g

-

Bag size:

-

L40-80mm W60-80mm

-

Machine name:

-

Nylon triangle tea bag packing machine

-

Dimension:

-

920(L)*840(W)*2600(H)mm

-

Weight:

-

450kg

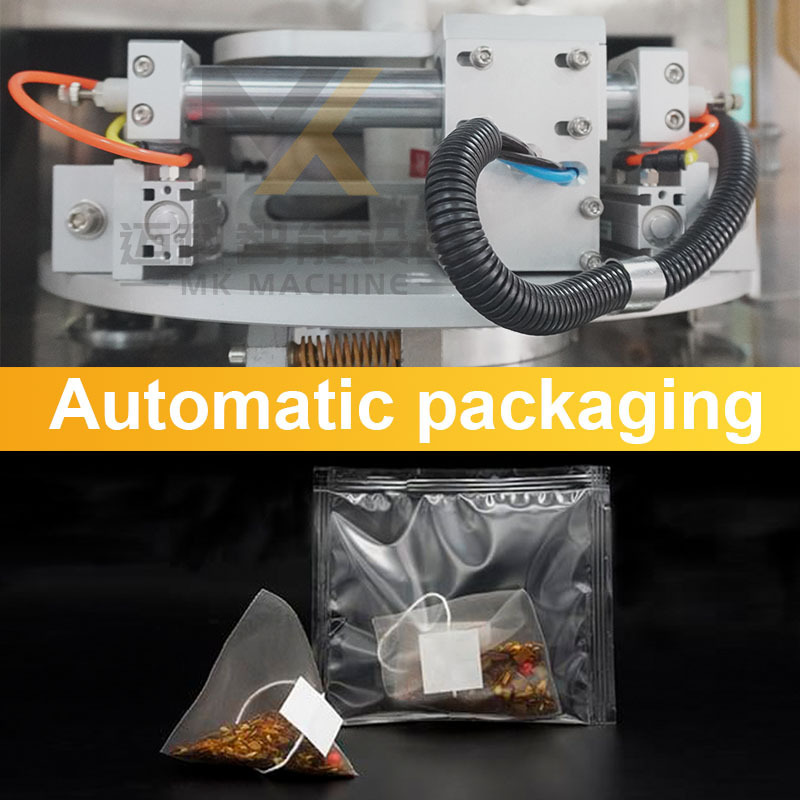

Automatic nylon triangle pyramids silk loose tea bag packing machine for inner and outer tea bag

1、The machine is suitable for green tea, black tea, scented tea, coffee, Chinese tea, health tea, herbal

tea, granule.

2、This unit can perform either a flat bag or triangle tea bag.

3、The machine can automatically finish the load, measuring, bag making, sealing, cutting, counting, finished product conveyor, and other functions.

4、Adopt the imported ultrasonic sealing, use the electronic scale metering to cutting-stock, perfect sealing,cutting-stock accuracy

5、Packing material: Nylon, Polyester net,non-woven fibers, corn fiber.

|

Measuring Scope

|

1-7g

|

|

Packing Speed

|

40bags/min

|

|

Inner bag size

|

L:40-80mm;W:60-80mm

|

|

Packing material

|

Nylon,Polyester net,non-woven fibries,corn fiber

|

|

Total Power

|

220V/50HZ/3.0kw

|

|

Dimension

|

920(L)*840(W)*2600(H)mm

|

|

Weight

|

450kg

|

A tea bag is a triangle, porous, sealed bag containing dried plant material, which is immersed in boiling water to make a hot drink. Tea bags are commonly made of filter paper or food-grade plastic, or occasionally of silk. Tea bag is commonly used to describe paper or foil packaging for loose leaves.

The machine can be used for patching tea,green tea, rose tea, black tea, red tea, ginger tea coffee, food etc granules.and coarse free-flowing powders.

Hopper

Discharging multiple barrels at the same time, electronic weighing method, accurate discharging.

Scales

Accurately weigh and unload materials according to the set weight.

Inner bag packaging film

Inner bag making and perfect sealing.

Cutting Device

After completing bag making and material filling, sealing and cutting.

Our Company

FAQ

1.How to find a solution suitable for my product?

Tell me about your product details:

1. What kind of product you have. 2. the size of your product.

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn't hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does packaging equipment cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at 'standard pricing' isn't usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process.

4.Which machines are available in-stock?

If your needs are fairly standard and straightforward, you may be able to snag an In-Stock Machine and get it delivered in just a few weeks! CALL US to ask about our current inventory.

5.What is your after sales services?

●

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

●

After the commissioning, we will package the equipment by standard export package for shipment.

●

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

●

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Hot Searches