- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

Stoker Grate Charcoal Coal Fired 5 ton Boiler for Feed Mill

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated steam capacity:

-

1-10 ton/h

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

Quick Details

-

Steam Production:

-

Max. 10t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XinLi

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

Stoker Grate Charcoal Coal Fired 5 ton Boiler for Feed Mill

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated steam capacity:

-

1-10 ton/h

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

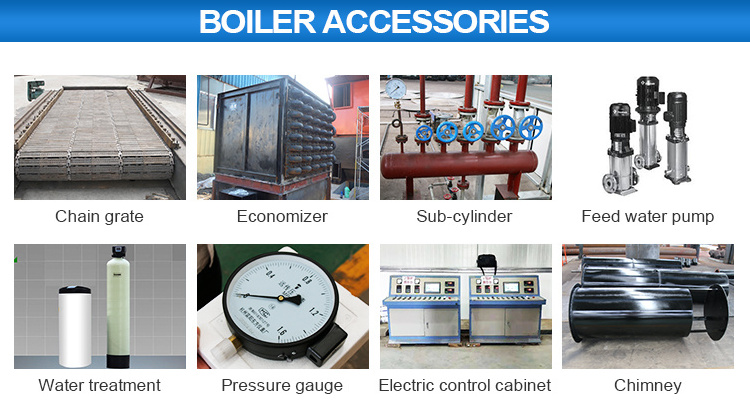

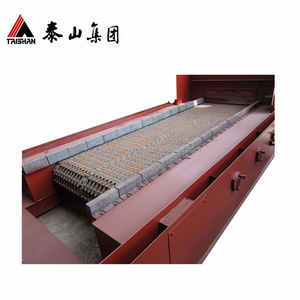

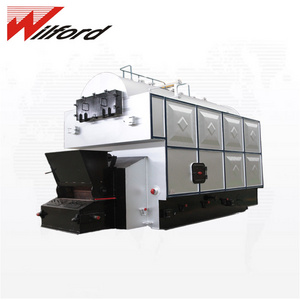

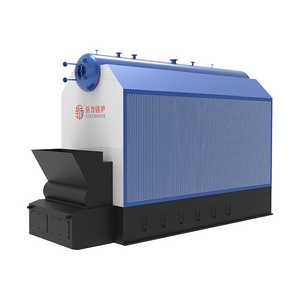

Stoker Grate Charcoal Coal Fired 5 ton Boiler for Feed Mill

Model:Chain Grate Stoker Type Boiler

Structure:Three Pass Single Drum

Fuel:Coal, Biomass, Wood, Chip, Husk, Sawdust, Jute, Shell, Waste Solid Fuel etc.

Capacity: 1 - 10 ton/h (1ton,2ton,4ton,6ton,8ton,10ton)

Pressure:0.7/1.0/1.25/1.6/2.5Mpa (7Bar/10Bar/12.5Bar/16Bar25Bar)

Temperature:170/184/194/204/225 C

Application:Food and Beverage,Textile,Plywood,Rice Mill,Chemical,Paper Mill,Rubber Plant etc

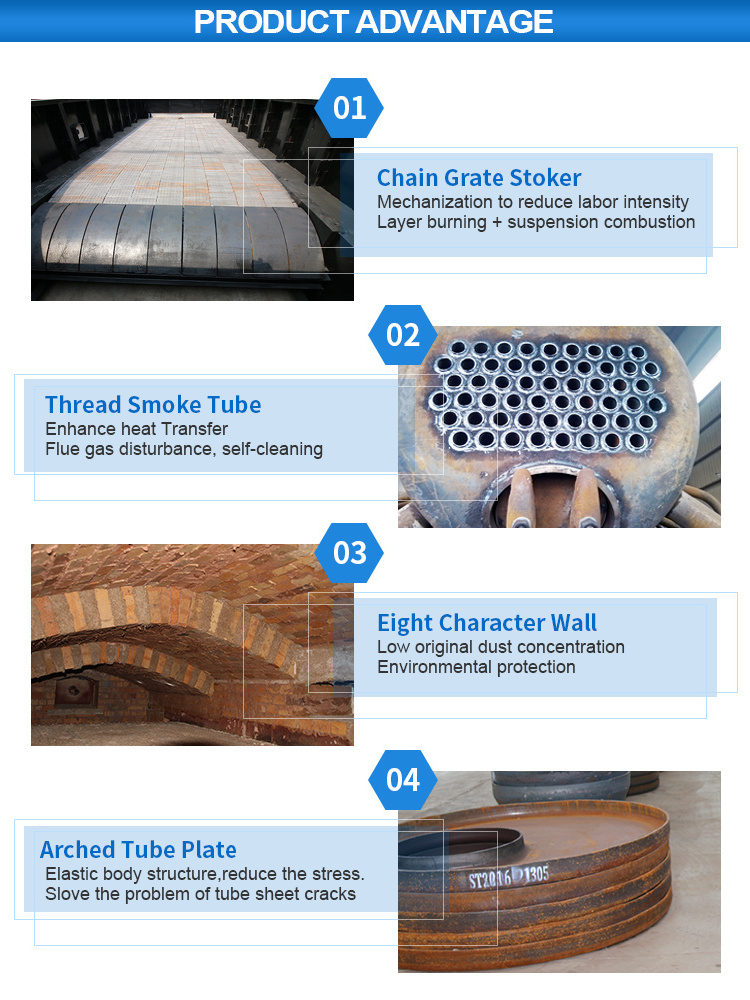

DZL seires coal/biomass fired steam boiler realizes almost zero pollution with the use of special dust collector solution (bag dust collector, double towers desulfurization, etc.). This series boiler is single drum horizontal type shell boiler, the combustion equipment is chain grate (small scale flaker is available), has the advantages of feed mechanically and strong adaptability of different fuels. The fuel could be II class bituminous coal, the diameter should be 6-25mm, and ash content should be less than 32.4%. Otherwise, DZL series boiler could also burn biomass fuel, including wood, straw, bagasse, rice husk, coconut shell, cotton seeds, peanut shell, etc.

|

Model Item |

DZL1 | DZL2 | DZL4 | DZL6 | DZL8 |

DZL10

(Assembly) |

DZL15

(Assembly) |

DZL20

(Assembly) |

|

|

Steam Capacity

(t/h) |

1 | 2 | 4 | 6 | 8 | 10 | 15 | 20 | |

|

Steam Pressure

(MPa) |

0.7/1.0/1.25 | 1.25/1.6 | |||||||

|

Steam Temperature

(℃) |

170/184/194 | 194/204 | |||||||

| Feed water Temperature(℃) | 20 | 20 | 20 | 20 | 20 | 70 | 70 | 70 | |

| Heating Area(m2) | Body | ~33 | ~50 | ~100 | ~170 | ~200 | ~250 | 316 | 502 |

|

Econom izer |

10.56/20.7 | 27.6 | 52.48/33.12 | 87.2 | 98 | 174 | 351 | 382 | |

|

Effective Grate

Area(m2) |

2.22 | 2.22 | 4.1 | 5.5 | 7.95 | 9.75 | 11.1 | 23.9 | |

| Fuel Type | II Bituminous Coal, Lower Heating Value Q≈21000KJ/Kg | ||||||||

| Fuel Consumption(kg/h) | ~151 | ~302 | ~600 | ~880 | ~1150 | ~1450 | ~2220 | ~1160 | |

| Exhaust Gas Temperature(℃) | 135-145 | ||||||||

| Thermal Efficiency(%) | 83-85 | ||||||||

| Weight of Biggest Part for Transportation(t) | 17 | 23 | 25 | 35 | 45 |

33(Up Part)

28(Down Part) |

42(Up Part)

35(Down Part) |

50(Up Part)

28(Down Part) |

|

|

Overall Dimension of Boiler Assembled

L*W*H(m) |

5.1×2.2×3 | 5.5×2.3×3.3 | 6.6×2.6×3.6 | 7.5×2.9×3.8 | 8.1×3.1×3.8 |

7.7×3.2×3.6

8.6×3.0×2.6 |

10×3.24×3.54

12×3.2×3.08 |

11×3.24×3.54

14×3.2×3.08 |

|