- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JM- BAR

-

Grade:

-

Pure titanium or titanium alloy

-

Ti (Min):

-

Over 95%

-

Strength:

-

900

-

material quality:

-

Pure titanium or titanium alloy

-

purity:

-

Over 99.5%

-

surface:

-

Polishing, pickling, sandblasting

-

density:

-

4.51 grams per cubic centimeter

-

colour:

-

silvery white

-

packing:

-

Wooden box

-

technology:

-

forge

-

type:

-

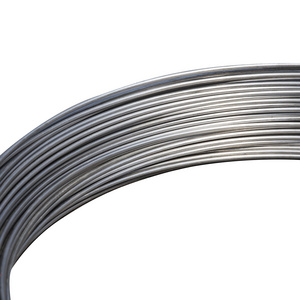

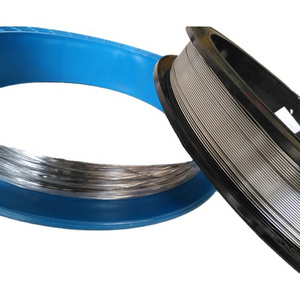

Straight type, coil type, and spool type

-

feature:

-

Low density and high strength

-

specifications:

-

customizable

Quick Details

-

Application:

-

medical, glasses, headwear, etc

-

Place of Origin:

-

baoji

-

Brand Name:

-

JM-TITANIUM

-

Model Number:

-

JM- BAR

-

Grade:

-

Pure titanium or titanium alloy

-

Ti (Min):

-

Over 95%

-

Strength:

-

900

-

material quality:

-

Pure titanium or titanium alloy

-

purity:

-

Over 99.5%

-

surface:

-

Polishing, pickling, sandblasting

-

density:

-

4.51 grams per cubic centimeter

-

colour:

-

silvery white

-

packing:

-

Wooden box

-

technology:

-

forge

-

type:

-

Straight type, coil type, and spool type

-

feature:

-

Low density and high strength

-

specifications:

-

customizable

Product Introduction

What is titanium wire

Titanium wire is a fine wire like material made of pure titanium or titanium alloy, which has the characteristics of lightweight, corrosion resistance, high strength, and high-temperature oxidation resistance. The density of titanium wire is 4.54g/cm ³, 43% lighter than steel, twice larger than aluminum, and five times larger than magnesium. Its tensile strength is between 1000-1400MPa, and its specific strength is higher than that of alloy steel. The melting point of titanium wire is 1942K, which is nearly 1000K higher than gold and nearly 500K higher than steel.

Application of titanium wire

Industries such as medical, sports equipment, glasses, earrings, headwear, electroplating pendants, welding wires, etc

The characteristics of titanium wire

A series of excellent characteristics such as high strength, non-magnetic, high biocompatibility, low impedance to ultrasound, and good shape memory function.

Details Images

Description

|

application

|

Chemical equipment, such as pipelines, heat exchangers, evaporators, heaters, reactors, etc

|

|

type

|

Straight type, coil type, and spool type

|

|

melting point

|

1668 ± 4 ℃

|

|

boiling point

|

3260±20℃

|

|

material

|

GR1 GR2 GR5 GR23

|

|

material quality

|

Pure titanium or titanium alloy

|

|

specifications

|

customizable

|

|

MOQ

|

5 kilogram

|

Production Process

Titanium wire production process

The titanium wire production process is a very complex process that requires multiple steps to complete. The following is a detailed introduction to the titanium wire production process.

Step 1: Preparation of raw materials

The production of titanium wire requires the use of high-purity titanium materials, and high-purity titanium blocks are generally prepared using the electric 3-furnace melting method or gas-phase deposition method. Then, high-purity titanium blocks are processed to produce bars or plates that meet the requirements.

Step 2: Processing of bars or plates

Cut, stretch, and process the qualified bars or plates to ensure that their size and shape meet the requirements. These processed bars or plates are called "busbars".

Step 3: Bus cleaning

The busbar may be contaminated and oxidized during the processing, so it needs to be cleaned. The cleaning methods include mechanical cleaning, chemical cleaning, and electrolytic cleaning.

Step 4: Bus annealing

In order to improve the ductility and plasticity of the busbar, annealing treatment is required. By controlling temperature and time, the internal structure of the busbar is changed to achieve a softening effect.

Step 5: Wire drawing

Send the annealed busbar into the wire drawing machine for wire drawing. The wire drawing machine gradually reduces the diameter of the busbar by continuously stretching it, ultimately turning it into the desired titanium wire.

Step 6: Titanium wire cleaning

The produced titanium wire needs to be cleaned to remove surface pollutants and oxides. The cleaning methods include mechanical cleaning, chemical cleaning, and electrolytic cleaning.

Step 7: Titanium wire detection

Inspect the produced titanium wire, including appearance quality, dimensional accuracy, chemical composition, and other aspects. Only titanium wires that meet the requirements can proceed to the next step of the process.

Step 8: Titanium wire processing

Process the titanium wire that meets the requirements to produce the desired shape and size of the product. The processing methods include cutting, welding, cold bending, etc.

Hot Searches