Yixing Holly Technology Co., Ltd is located in Yixing, Jiangsu Province, China. Established in 2007, Holly Technology is a domestic forerunner in producing environmental equipments and parts used for sewage treatment.

Nowadays, our company has developed into a comprehensive enterprise integrating production, trading, design and installation

service of sewage treatment equipments.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Sewage Dewatering

-

Material:

-

ss304

-

Capacity:

-

0.5-20m3/h

-

Feed concentration:

-

30-40%

-

Service life:

-

More than 15 years

-

Color:

-

Customerized

-

Usage:

-

Sludge Filter Press

-

Certification:

-

ISO9001

-

Product name:

-

Belt Press Dehydrator

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Holly

-

Weight:

-

1000 kg, 1000-8000kg

-

Application:

-

Sewage Dewatering

-

Material:

-

ss304

-

Capacity:

-

0.5-20m3/h

-

Feed concentration:

-

30-40%

-

Service life:

-

More than 15 years

-

Color:

-

Customerized

-

Usage:

-

Sludge Filter Press

-

Certification:

-

ISO9001

-

Product name:

-

Belt Press Dehydrator

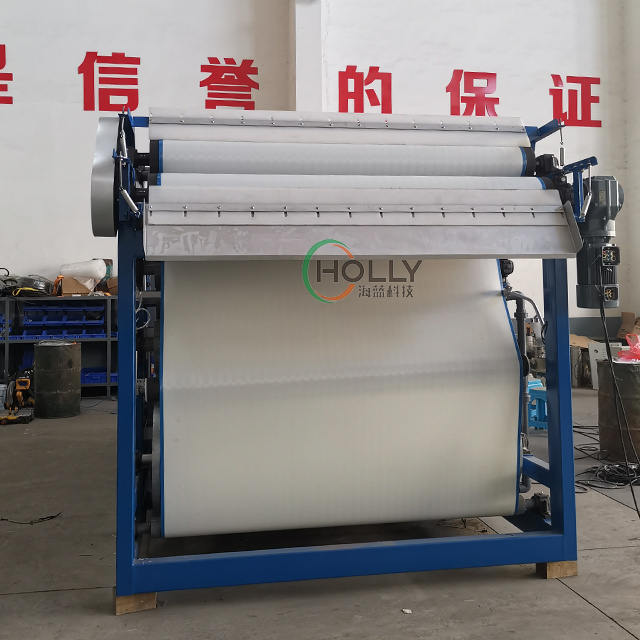

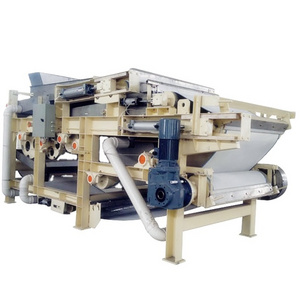

The belt filter press is designed and manufactured by our factory.

It has S-shaped filter belt, so the pressure of sludge is gradually increased and eased.

It is suitable for the dewatering of organic hydrophilic materials and inorganic hydrophobic materials.

Due to lengthening the settling zone, this series of press filter has rich experience in filter pressing and dewatering of

different types of materials.

It has S-shaped filter belt, so the pressure of sludge is gradually increased and eased.

It is suitable for the dewatering of organic hydrophilic materials and inorganic hydrophobic materials.

Due to lengthening the settling zone, this series of press filter has rich experience in filter pressing and dewatering of

different types of materials.

|

Model

Item

|

DNY

500 |

DNY

1000A |

DNY

1500A |

DNY

1500B |

DNY

2000A |

DNY

2000B |

DNY

2500A |

DNY

2500B |

DNY

3000 |

||||||||

|

Output Moisture Content(%)

|

70-80

|

|

|

|

|

|

|

|

|

||||||||

|

Polymer Dosing Rate(%)

|

1.8-2.4

|

|

|

|

|

|

|

|

|

||||||||

|

Dried Sludge Capacity (kg/h)

|

100-120

|

|

300-360

|

300-360

|

400-460

|

400-460

|

470-550

|

|

600-700

|

||||||||

|

Belt Speed (m/min)

|

1.57-5.51

|

|

1.04-4.5

|

|

|

|

|

|

|

||||||||

|

Main Motor Power (kW)

|

0.75

|

|

1.1

|

|

|

|

1.5

|

|

|

||||||||

|

Mixing Motor Power(kW)

|

0.25

|

|

0.37

|

|

0.55

|

|

|

|

|

||||||||

|

Effective Belt Width (mm)

|

500

|

|

1500

|

|

2000

|

|

2500

|

|

3000

|

||||||||

|

Water Consumption (m3/h)

|

6.2

|

|

16

|

17.6

|

20.8

|

22.4

|

24.1

|

25.2

|

28.8

|

||||||||

1. Material of the main structure :

SUS304/316

2. Belt : Has a long service life

3. Low power consumption, slow-speed of revolution and low noise

4. Adjustment of belt: Pneumatic regulated, ensures the stability of the machine

5. Multi-point safety detection and emergency stop device:improve the operation.

6. The design of the system is obviously humanized and provides convenience in operation and maintenance.

2. Belt : Has a long service life

3. Low power consumption, slow-speed of revolution and low noise

4. Adjustment of belt: Pneumatic regulated, ensures the stability of the machine

5. Multi-point safety detection and emergency stop device:improve the operation.

6. The design of the system is obviously humanized and provides convenience in operation and maintenance.

printing and dyeing sludge, electroplating sludge,

papermaking sludge, chemical sludge, municipal sewage sludge,

mining sludge, heavy metal sludge, leather sludge,

drilling sludge, brewing sludge, food sludge,

papermaking sludge, chemical sludge, municipal sewage sludge,

mining sludge, heavy metal sludge, leather sludge,

drilling sludge, brewing sludge, food sludge,

Yixing Holly Technology

Hot Searches