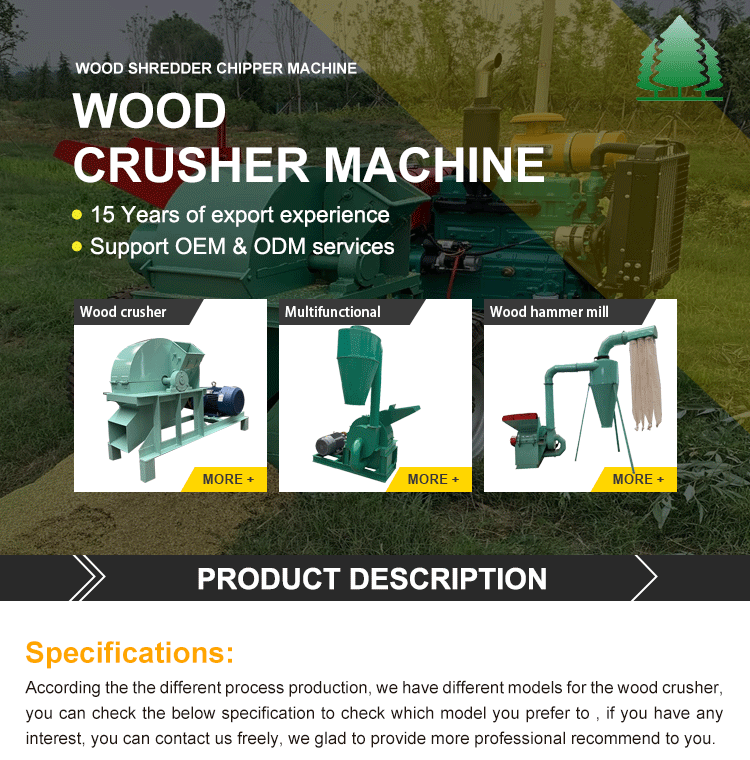

It is a forestry processing equipment that processes wood materials such as wood and branches into sawdust and sawdust. Widely used in power plants, paper mills, charcoal production lines and other industries. The machine is mainly composed of a cutter head, a crushing chamber and a screen. The fineness of the sawdust can be adjusted and adjusted by changing the screen. The performance of the machine has been greatly improved compared with other similar products.

wood chipper machine

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

85 KG

-

Marketing Type:

-

Hot sale in 2022

-

Product name:

-

wood chipper machine

-

Keywords:

-

wood chipper machine

-

Application:

-

Making wood chips and sawdust

-

Engine:

-

Gasoline/Electric

-

Material:

-

Wood Branch/Wood sticks

-

Package:

-

Wooden Carton

-

Starting System:

-

Pull Start

-

Chip capacity:

-

4/5/6/7/9 Inch

-

Usage:

-

Wood Shredder Cutting Wood Branch

-

After-sales Service Provided:

-

Online

Quick Details

-

Use:

-

wood chipper machine

-

Place of Origin:

-

Henan, China

-

Dimension(L*W*H):

-

1800X800X1150mm

-

Weight:

-

85 KG

-

Marketing Type:

-

Hot sale in 2022

-

Product name:

-

wood chipper machine

-

Keywords:

-

wood chipper machine

-

Application:

-

Making wood chips and sawdust

-

Engine:

-

Gasoline/Electric

-

Material:

-

Wood Branch/Wood sticks

-

Package:

-

Wooden Carton

-

Starting System:

-

Pull Start

-

Chip capacity:

-

4/5/6/7/9 Inch

-

Usage:

-

Wood Shredder Cutting Wood Branch

-

After-sales Service Provided:

-

Online

Product Description

It is a new style and widely used machine. Its widely used in all kinds of crop stalk, cotton firewood, straw, clover, peanuts shells, cotton seed fur, etc. This series of machine have advantages of compact structure, strong and durable, safe and reliable, easy operation, lower noise and vibration, high efficiency and low energy consumption, etc. And the spare part of the machine completely adopt quality material, outsourcing parts adopting domestic optimal product,the whole machine’s quality is reliable, long-lived.

wood chipper machine

Machine Details and Features

|

Features of Branch Leaf Diesel Wood Chipper Shredder

|

|

1.Low noise and small machine and small footprint

wood chipper machine

|

|

2.Compact and simple

wood chipper machine

|

|

3.High output and low energy consumption

w

ood crusher machine for sawdust powder

|

|

4.Wide range of applications

wood crusher machine for sawdust powder

|

Product Paramenters

|

Disc wood crusher is fit for wood diameter 3-27cm

|

|

|

|

|

||||

|

Model

|

ZS-MC420

|

ZS-MC500

|

ZS-MC600

|

ZS-MC1000

|

||||

|

Capacity(kg/h)

|

300-1500

|

500-2000

|

800-3000

|

1500-5000

|

||||

|

Power(kw)

|

15

|

22

|

30

|

55

|

||||

|

Cut Diameter(mm)

|

420

|

500

|

600

|

1000

|

||||

|

Input Size

|

17*15cm

|

20*17cm

|

22*19cm

|

27*25

|

||||

Production Details

The structure is simple, the arrangement is compact, the price is cheap, the work is stable, the energy consumption is low, the output is high, the finished product of the sawdust machine is of good quality, and the processing cost is low.

wood crusher machine for sawdust powder

Wood Chipper Shredder Application

Related Products

For different materials and different output requirements, you can choose electric or diesel models as power!

wood crusher machine for sawdust powder

We have a complete wood pellet production line, please tell me what is your raw material, what is the finished product you want, and what is the output you need. I will provide you with the most professional recommendations and free solutions.

wood crusher machine for sawdust powder

Why Choose Us

Pre-sale services:

1.Design and manufature machines according to your special needs.

2.Provide project design, process design, andpurchase program for you.

3.Help you formulate construction scheme. We have a professional responsing-team for you

On-sale services:

1.Check the performance of the machine and help finish the shipment for you.

2.Standard export package or as your demand

After-sale service:

1.send engineers to install them, commissioning and training operators on site.

2. Repairing and maintenance if any problem occur in the warranty.

3.Spare and wearing parts for free or with big discount.

4.Any feedback of machines can be told us, and we will try our best to support you.

2.Provide project design, process design, andpurchase program for you.

3.Help you formulate construction scheme. We have a professional responsing-team for you

On-sale services:

1.Check the performance of the machine and help finish the shipment for you.

2.Standard export package or as your demand

After-sale service:

1.send engineers to install them, commissioning and training operators on site.

2. Repairing and maintenance if any problem occur in the warranty.

3.Spare and wearing parts for free or with big discount.

4.Any feedback of machines can be told us, and we will try our best to support you.

Hot Searches