- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11700x7710x12200mm

-

Weight:

-

46000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feeding Size(mm):

-

<38 to 55 mm

-

Colour:

-

White, Yellow or Grey

-

Performance:

-

Perfect

-

Maintenance:

-

Convenient

-

Environmental Friendly:

-

Yes

-

Technology Service:

-

We can supply

-

Spare parts supply:

-

Yes

-

Factory Visit:

-

Factory Visit any time

-

input moistrure:

-

<15%

Quick Details

-

Capacity(t/h):

-

7 to 100 tph

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LIMING

-

Dimension(L*W*H):

-

11700x7710x12200mm

-

Weight:

-

46000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feeding Size(mm):

-

<38 to 55 mm

-

Colour:

-

White, Yellow or Grey

-

Performance:

-

Perfect

-

Maintenance:

-

Convenient

-

Environmental Friendly:

-

Yes

-

Technology Service:

-

We can supply

-

Spare parts supply:

-

Yes

-

Factory Visit:

-

Factory Visit any time

-

input moistrure:

-

<15%

Notice For Price:

1. The configuration and price are different according to different requirements.

2. All prices on this page are auto-generated virtual prices. Please contact us for quotation!

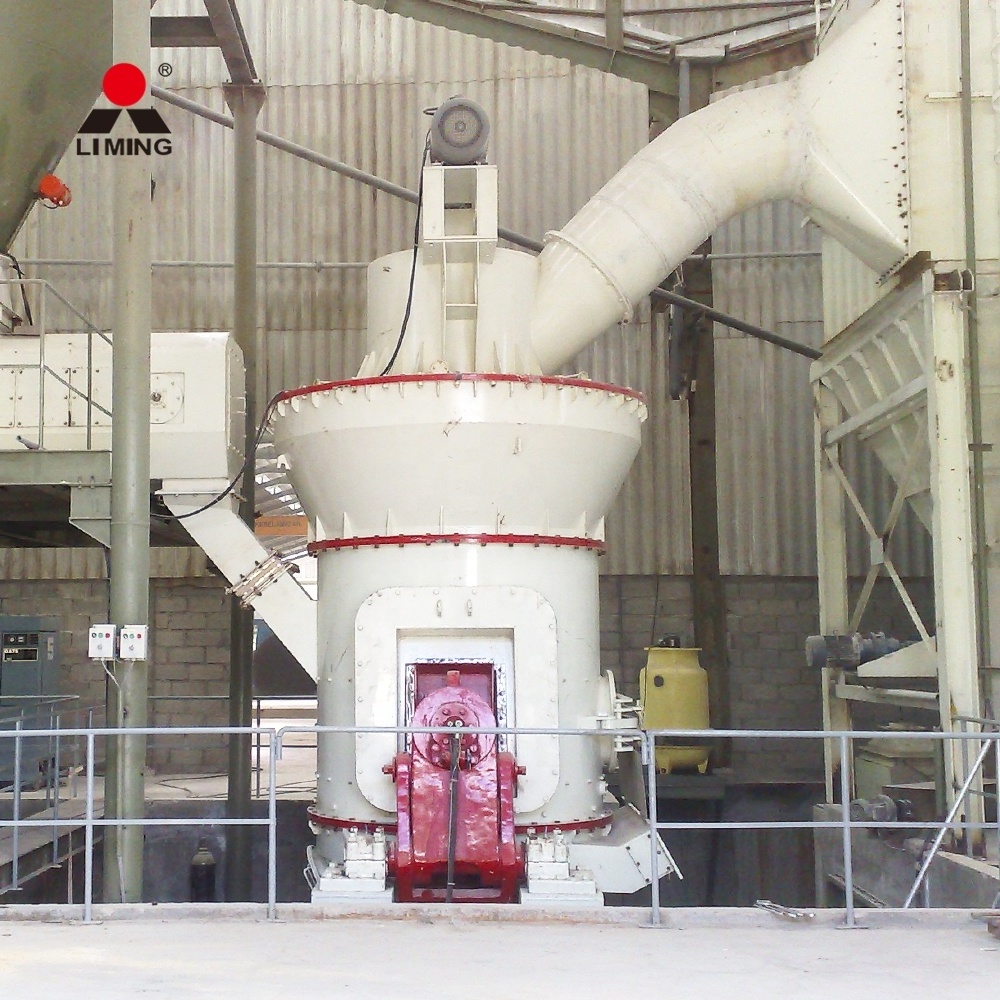

Vertical Roller Mill Coal Pulverizer In Cement Industry Price

|

Vertical Roller Mill Coal Pulverizer In Cement Industry Price

is one advanced mill, adopting top technology domestic and abroad, and based on many years’ mill experiences. It can crush, dry, grind, and classify the materials.

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing non-metallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%-40% similarly. |

| LM Vertical Mill |

Technical Parameters

|

Series |

Coal mill |

|||||

|

Model |

LM150M |

LM170M |

LM190M |

LM220M |

LM240M |

|

|

Capacity (t/h) |

16~22 |

20~28 |

26~35 |

35~45 |

40~50 |

|

|

fineness (R0.08) |

<15% |

<15% |

<15% |

<15% |

<15% |

|

|

Coal powder moisture |

<1% |

<1% |

<1% |

<1% |

<1% |

|

|

Max.input size (mm) |

<40 |

<42 |

<45 |

<50 |

<55 |

|

|

input moistrure |

<15% |

<15% |

<15% |

<15% |

<15% |

|

|

Inlet air temperature (℃) |

<350 |

<350 |

<350 |

<350 |

<350 |

|

|

Outlet air temperature (℃) |

75~95 |

75~95 |

75~95 |

75~95 |

75~95 |

|

|

Dimension

|

Lmm |

4200 |

4700 |

8500 |

10200 |

11700 |

|

Wmm |

3900 |

4500 |

5600 |

6700 |

7710 |

|

|

H mm |

7100 |

8300 |

8800 |

10600 |

12200 |

|

|

Weight (t) |

75 |

94 |

100 |

122 |

157 |

|

Customer Sites

Related Products

Our Strength

| ♦ We are manufacturer of stone crushers and grinding mills since 1987. |

| ♦ We follow the standard of CE, ISO9001, Ghost, CU-TR. |

| ♦ Our factory convers 150000 m³. Welcome to see machines! |

| ♦ We send engineers for installation, commissioning and training. |

| ♦ We have sufficient spare parts in stock. |

| ♦ We have lots of production sites running aroud the world. |

| ♦ Fast maintenance system to deal with customers's after sales issue in time. |

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total prices should be paid by T/T as down payment; 70% balance payment should b paid by T/T before delivery.

Q4: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. And we will supply the spare parts for you at lowest cost.

Q5: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.

Thanks for your trust! We can provide you with design scheme for complete production lines according to your demands and the site conditions. In order to recommend a suitable model for you and send you a best quotation. So please give us more information about your requirement.

1. What is the raw material to be processed?

2. What is your required capacity (t/h)?

3. What is the input size of the raw material?

4. What is the output size of the product you want?

Look forward to your inquiries! We will recommend the proper machine for you!