Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Custom Stainless Steel Fabrication CMP302

-

Brand Name:

-

LML Custom Stainless Steel Fabrication

-

OEM:

-

Offered

-

Color:

-

As per requirement

-

Finish:

-

As per requirement

-

Tolerance:

-

0.003mm~0.01mm

-

Application:

-

Mechanical Parts & Fabrication Service

-

Sample:

-

Custom Stainless Steel Fabrication available

-

Processing:

-

CNC Machining

-

Inspection:

-

100% before shipment

-

R&D:

-

8 engineers for Custom Stainless Steel Fabrication

-

Certificate:

-

ISO for Custom Stainless Steel Fabrication

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Custom Stainless Steel Fabrication CMP302

-

Brand Name:

-

LML Custom Stainless Steel Fabrication

-

OEM:

-

Offered

-

Color:

-

As per requirement

-

Finish:

-

As per requirement

-

Tolerance:

-

0.003mm~0.01mm

-

Application:

-

Mechanical Parts & Fabrication Service

-

Sample:

-

Custom Stainless Steel Fabrication available

-

Processing:

-

CNC Machining

-

Inspection:

-

100% before shipment

-

R&D:

-

8 engineers for Custom Stainless Steel Fabrication

-

Certificate:

-

ISO for Custom Stainless Steel Fabrication

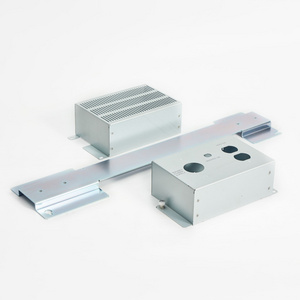

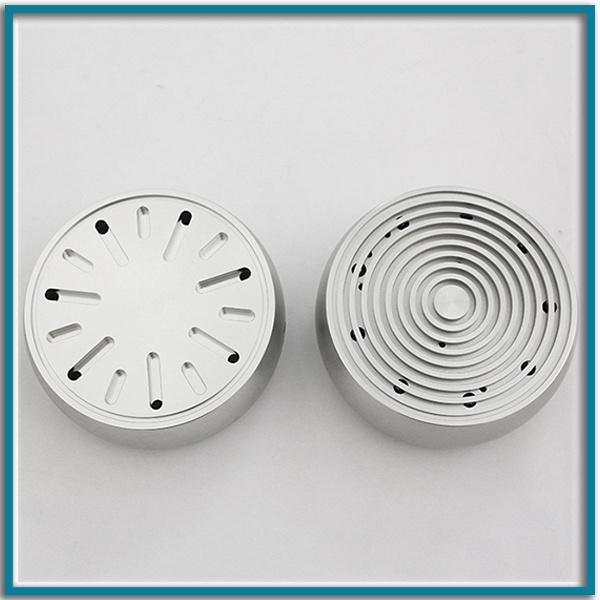

Custom Stainless Steel Fabrication

Looking something like a drill press, a milling machine uses a cutting tool that moves in all three dimensions, removi n g material to achieve the desired part shape. The cutting tool usually rotates about an axis that is perpendicular to the table that holds the material to be cut. A cutting tool protrudes down from a rotating spindle. A block of material is placed on a moving table below the cutter. While the cutting tool turns, a computer controls the vertical (Z axis) motion of the cutter and the horizontal (X and Y axis) motion of the block of material. The cutter is guided to move through the material, removing portions to create shapes. Additionally, the material can be turned to various orientations in the middle of the process and cutting tools of various shapes can be used.

.

.

Tolerance : 0.003~0.01mm

Intended Application

:

Armatures/ Axles/ Bolts/ Bushings/ Coupling Shafts/ Dowels/ Driveshafts/ Fasteners/ Handles/ Housings/ Knobs/ Needle Valves/ Nozzles/ Pins/ Pivot Rods/ Precision Electronic Hardware/ Punch Blanks/ Shafts/ Shanks/ Sleeves/ Spacers/ Terminals/ Valve Bodies/ Valve Stems/

Features Possible

:

Turning/

Boring/ Broaching/ Cross tapping/ Custom tapering/ Drilling/ Eccentric Holes/ External Splining/ Grinding/ Knurling/ Milling/ Slotting/ Splining/ Thread milling/ Threading external/ Threading internal/ Thread whirling/ Pointing/ Reaming/ Tapping

Materials

:

Alloy Steels (4130, 4140)

Aluminum (2011 6061-T6, 2024)

Beryllium

Brass

Bronze Alloys

Carbon Steel (12L14, 1215)

Carbide

Copper

Nickel

Stainless Steel (303, 304, 316, 321, 303SE, 420, 440C, 17-4)

Plastic Polymers

And much more!

LML is specialized in all kinds of metal products. Strong R&D capacity and strict quality control system enable us to meet customer's unique and difficult products. We can manufacture nonstandard metal products with high quality and competitive price.

Welcome to send us drawings for your custom metal products!

Website

For more similar products, please enter our website:

Alibaba Website: http://lmlmetalwork.en.alibaba.com/

Official Website: http://www.lmlmetalwork.com/

1.

What do you need to provide a quote?

Please kindly send us the drawing of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quoting. We couldn’t quote the specific price without any of them.)

2. How does the payment process work?

Payment terms are flexible for us in accordance with specific conditions. Generally we advise

30%TT deposit, balance be paid before shipment.

3. How do I know about the production?

We will double confirm your requirements and send you the sample before the mass production. During the mass

production, we will keep you informed of any progress. Besides, we will do 100% quality inspection before shipment.

4. How do I know about the delivery?

We will inform you of the tracking number once we get it from shipping agent. Also we will keep updating the latest

shipping information for you.

5. What will you do for after sales?

When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our

metal parts, our experienced engineers are ready to help.