- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

A-036

-

Main Structure:

-

steel column & steel beam

-

Secondary Structure:

-

Purlin; Brace; Knee Brace etc

-

Cladding:

-

PU/Rock Wool/Fiberglass/EPS

-

Accessories:

-

Skylight Belt; Ventilator; Downspout;Gutter etc

-

Application Fields:

-

cattle shed

-

Main Frame:

-

H Beam

-

Purlin:

-

C.Z Shape Steel

-

Material:

-

Q235Q345 Low Carbon Steel

Quick Details

-

Grade:

-

Q235 Q345B, Steel Q345B (S355JR; ASTM 50Ksi);Q235B (S235JR)

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

A-036

-

Main Structure:

-

steel column & steel beam

-

Secondary Structure:

-

Purlin; Brace; Knee Brace etc

-

Cladding:

-

PU/Rock Wool/Fiberglass/EPS

-

Accessories:

-

Skylight Belt; Ventilator; Downspout;Gutter etc

-

Application Fields:

-

cattle shed

-

Main Frame:

-

H Beam

-

Purlin:

-

C.Z Shape Steel

-

Material:

-

Q235Q345 Low Carbon Steel

Product Application

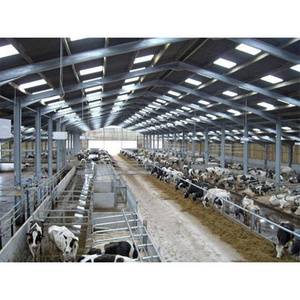

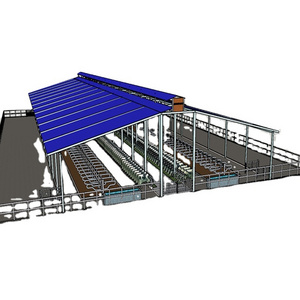

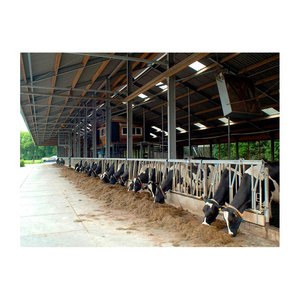

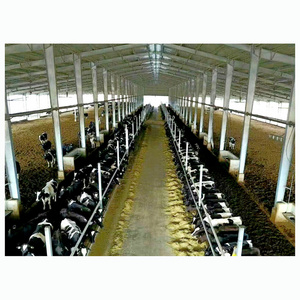

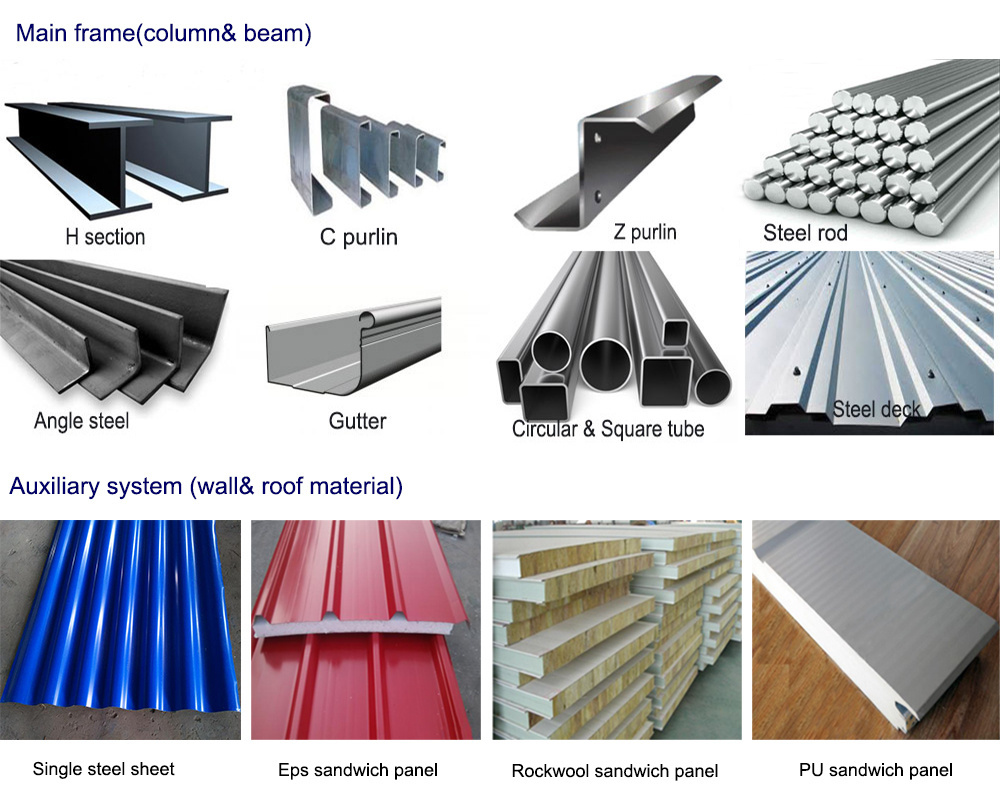

Light Frame Design Cattle Shed Cattle Farm Prefabricated Steel Steel Building

Steel Structure Dairy Farm, Cattle Shed, Cow Barn, is a modern building for cow cattle, beef cattles etc.

It use H steel as column and beam, supporting by C/Z purlins, tie rod, X brace etc, and wall and roof are covering by color steel sheet or Insulated sandwich panel (PU/EPS/Rockwool.Fiberglass). It has the advantage of shorter building time, eco friendly and modern design, lower investment etc comparing with tradtional concrete building.

|

SPECIFICATION FOR STEEL STRUCTURE BUILDING

|

|

|

||

|

|

|

1. Material: Q345B (S355JR) or Q235B(S235JR)

Welded/Hot Rolled H section steel |

||

|

|

|

2. Surface: Hot Dip Galvanized or Painted;

|

||

|

|

|

3. Connection: All Bolts Connection;

|

||

|

|

Roof Purlin

|

C or Z Section Steel, Q235B

|

||

|

|

Wall Purlin

|

C or Z Section Steel, Q235B

|

||

|

|

Bracing

|

Steel Rod, Q235B

|

||

|

|

Cross Support

|

Steel Rod, Q235B

|

||

|

|

Column Support

|

Angle Steel; Steel Rod; Q235B

|

||

|

|

Angle Brace

|

Angle steel,Q235B

|

||

|

|

Tie Bar

|

Steel Pipe,Q235B

|

||

|

|

Roof & Wall System

|

1. Single Colorful Corrugated Steel Sheet;

Thickness: 0.3-0.8mm |

||

|

|

|

2. Sandwich Panel with EPS, Rock Wool, Fiberglass,PU;

Thickness: 50-150mm; |

||

|

|

Door

|

Sliding; Rolled Up Door (Manual/Auto)

|

||

|

|

Window

|

Aluminum Alloy; PVC;

|

||

|

|

Downspout

|

PVC pipe;

|

||

|

|

Gutter

|

Galvanized Steel Sheet; Stainless Steel

|

||

|

|

Ventilator

|

Stainless Steel Turbine Ventilator

|

||

|

|

Skylight Belt

|

FRP or PC semi-transparent Skylight Belt

|

||

|

|

Flash

|

Color Steel Sheet

|

||

|

|

Fittings

|

Anchor Bolt; High Strength Bolt; Orindary Bolt, Self-tapping nail etc

|

||

Head Lock

Bed

Fan

Curtain

Installation Process

Factory Introduction

Our Factories covers an area of 20 thousand square meters which is specialized in designing,manufacturing and installation of steel structure products.The company has two professional production lines, the annual output reaches 30 thousand tons.It also owns professional design team,two senior structural engineers, three senior architects, three senior engineers, sixty professional processing staffs. Our company has three-grade steel structure construction qualification and passed the ISO9000 international systems Certifications.

stucture, the edge is well wrapped by fabric cloths, the purlins are bundles, and color steel sheet is well packed by kraft paper, as to the accessories and small spart parts are put into plywood board;

|

1. Free Designing Service

|

We have professional design teams, we can provide full detailed drawings based on your requirements; The software we use :Auto CAD, Tekla, PKPM, MTS, 3D3S, Tarch etc;

|

|

|

||

|

2. Quality Control & Quality Assurance Service

|

Since raw material, each processing procedure, finished products; every procedure, we have professional quality control staff to test the quality; ensure each procedure finished product is qualified,so the final finished product quality is highly guaranteed;

We also accept, clients send 3rd party testing organization to come to our factory to check the quality or supervise the container loading; Furthermore, we can make deal by Alibaba Trade Assurance; |

|

|

||

|

3. Installation Service

|

We will provide detailed drawing for installation; if need, we can also send our engineer to overseas to guide installation.

|

|

|

||