- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

HX-DT102

-

Product Name:

-

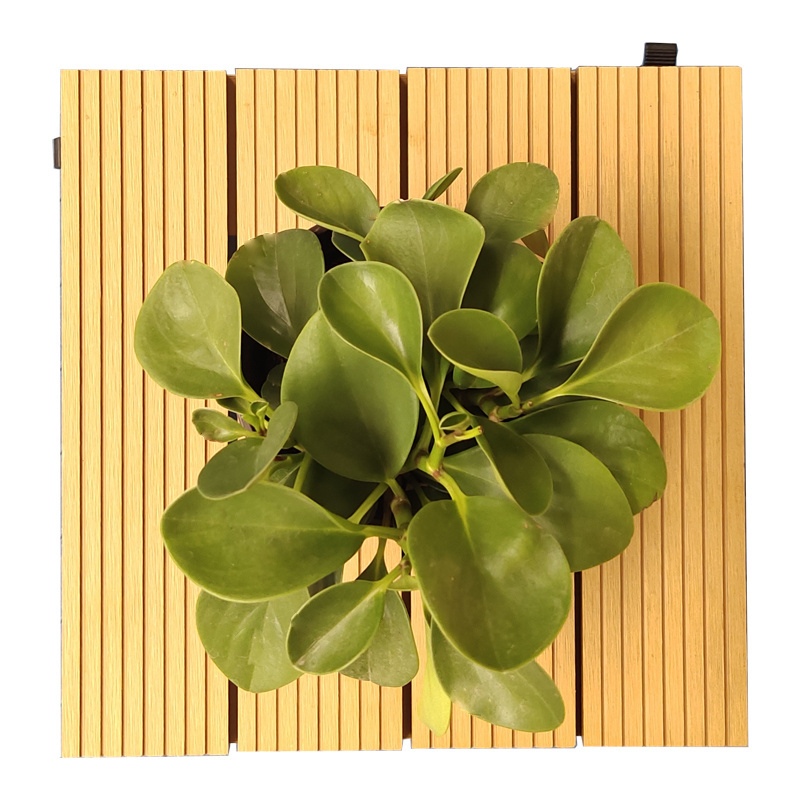

Wpc Plant Caddy

-

Color:

-

Dark grey/Light grey/Teak/Red wood/Red brown/Coffee

-

Application:

-

Balcony Garden

-

Usage:

-

Home Garden

-

Size:

-

30*30*8cm

-

Packing:

-

carton

-

MOQ:

-

1000pcs

-

Certificate:

-

CE

-

Advantage:

-

Environment-friendly

Quick Details

-

Usage Condition:

-

Desktop, Home, Garden, plant engineering, Hotel

-

Design Style:

-

Modern

-

Material:

-

WPC

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

HX-DT102

-

Product Name:

-

Wpc Plant Caddy

-

Color:

-

Dark grey/Light grey/Teak/Red wood/Red brown/Coffee

-

Application:

-

Balcony Garden

-

Usage:

-

Home Garden

-

Size:

-

30*30*8cm

-

Packing:

-

carton

-

MOQ:

-

1000pcs

-

Certificate:

-

CE

-

Advantage:

-

Environment-friendly

Product Description

|

Product Name

|

Wpc Plant Caddy

|

Colour

|

Coffee/dark grey/Light grey/Teak/Red wood/Red brown

|

|

Brand

|

HUAXU

|

Model Number

|

HX-DT102

|

|

Surface

|

Wood Grain,Flat

|

Place of Product

|

Zhejiang, China

|

|

Technics

|

Wood-Plastic Composite Flooring

|

Modes of packing

|

cartons

|

|

Size

|

300*300*80mm

|

Thickness

|

Above 78mm

|

|

Certificate

|

CE

|

Product material

|

PE+wood powder

|

|

features

|

UV-resistant,waterproof

|

Function

|

waterproof , corrosion resistance,anti UV

|

Related Products

Company Introduction

Anji Huaxu WPC Environmental Protection Materials CO, LTD, located in Anji county who is the most beautiful town in China, is specialized in producing WPC products with its strong capability of development and production. With advanced production lines and high capacity equipment, we produce many types of WPC products such as decking, railing&fence, outdoor flooring, recycled plastic umber, garden ornaments and so on. More than 60 types of WPC proles have been researched and ploughed into market, herewith it's very popular in North America, Europe etc.

We warmly welcome all customers to visit our factory for negotiation.

Exhibition

Certificate

Factoty

HUAXU WPC is a leading supplier of composite products with over 10 years' experience in producing durable,

performance-improving and cost-effective composite solutions to a wide range of industries. We help companies of all sizes unlock the power of composites, and our client base includes businesses in the Industrial, Construction, Rail, Transport, Landscaping,Marine and Leisure sectors.

There are reasons we believe to make us a qualified& satisfied supplier to our clients:

1. By more than 30 extrusion lines, we are able to ship out more than 100 containers per month.

2. 30% of our annual profits would be invested in R&D, which enables us to obtain much more experience in composite products' upgrade than our competitors. For each year we launch new products in different product categories, which provides our clients with more options.

3. Based on our marketing research, we are confident to offer our clients competitive prices based on reliable qualities. We have our client base growing by 20% year on year.

4. We have our products tested by third parties, such as SGS, TUV and Intertek to issue formal quality testing reports and we assure our clients of punctual lead time. We are proud of our sales network having extended to more than 60 countries all over the world, and it keeps growing.

5. We care a lot about sales& field installation. From start to finish, our sales representatives, installation builders and

after-sales attendants are always ready of service. For any question regarding any aspect of the composite products we can provide you professional advice and solutions.

1. By more than 30 extrusion lines, we are able to ship out more than 100 containers per month.

2. 30% of our annual profits would be invested in R&D, which enables us to obtain much more experience in composite products' upgrade than our competitors. For each year we launch new products in different product categories, which provides our clients with more options.

3. Based on our marketing research, we are confident to offer our clients competitive prices based on reliable qualities. We have our client base growing by 20% year on year.

4. We have our products tested by third parties, such as SGS, TUV and Intertek to issue formal quality testing reports and we assure our clients of punctual lead time. We are proud of our sales network having extended to more than 60 countries all over the world, and it keeps growing.

5. We care a lot about sales& field installation. From start to finish, our sales representatives, installation builders and

after-sales attendants are always ready of service. For any question regarding any aspect of the composite products we can provide you professional advice and solutions.

Transport

FAQ

Q: What are the main advantages of WPC products?

First of all, the wood plastic materials are 100% recyclable; it is long-lasting, stable for the outdoor conditions, like sun

exposure, rain, temperature ariations etc; it requires low maintenance; etc

Q: Why the keel is necessary for the intallation?

When we install the flooring, firstly the keels are fixed in the ground surface with the T-clip and then we put the solid decking board on the keels. You know the wpc decking board can’t be put on the ground surface directly. For one thing, it can affect of the planeness of the flooring surface after installation. For the other thing, it is not good to control the drainage of the bottom, because the wpc decking board is mainly used for outdoor, which rains a lot. So keels must be used to hold the solid decking board when installed.

Q: If there is one piece of the decking board broken, do we need to remove all the decking board to repair it?

No. If replce the broken decking, you need to break the clips of both sides of the broken decking and then take the broken decking out, it’s easy.

Q: What temperature the decking can bear?

-40°to 60°

Q: The density and the strength of the decking?

The density of our wpc decking is 1.3%-1.4%(1300-1400kgs/cbm). The strength of the hollow one is about 320kgs (That’s to say, based on the space between the keels of 35cm, the decking surface can bear the weight of 320kgs.) and the strength of the solid one is 400kgs-500kgs.(That’s to say, based on the space between the keels of 35cm, the decking surface can bear the weight of 400kgs-500kgs.)

Q: Will color fade because of exposure to the sun?

ULTRA-VIOLET inhibitors have been added to our decking to reduce color fading due to extensive sun exposure. A slight change in color will occur but will retain this lighter shade through out the life of the product.

First of all, the wood plastic materials are 100% recyclable; it is long-lasting, stable for the outdoor conditions, like sun

exposure, rain, temperature ariations etc; it requires low maintenance; etc

Q: Why the keel is necessary for the intallation?

When we install the flooring, firstly the keels are fixed in the ground surface with the T-clip and then we put the solid decking board on the keels. You know the wpc decking board can’t be put on the ground surface directly. For one thing, it can affect of the planeness of the flooring surface after installation. For the other thing, it is not good to control the drainage of the bottom, because the wpc decking board is mainly used for outdoor, which rains a lot. So keels must be used to hold the solid decking board when installed.

Q: If there is one piece of the decking board broken, do we need to remove all the decking board to repair it?

No. If replce the broken decking, you need to break the clips of both sides of the broken decking and then take the broken decking out, it’s easy.

Q: What temperature the decking can bear?

-40°to 60°

Q: The density and the strength of the decking?

The density of our wpc decking is 1.3%-1.4%(1300-1400kgs/cbm). The strength of the hollow one is about 320kgs (That’s to say, based on the space between the keels of 35cm, the decking surface can bear the weight of 320kgs.) and the strength of the solid one is 400kgs-500kgs.(That’s to say, based on the space between the keels of 35cm, the decking surface can bear the weight of 400kgs-500kgs.)

Q: Will color fade because of exposure to the sun?

ULTRA-VIOLET inhibitors have been added to our decking to reduce color fading due to extensive sun exposure. A slight change in color will occur but will retain this lighter shade through out the life of the product.

Hot Searches