- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

5400 KG

-

Keyword:

-

Semi Automatic Rotary Die Cutting Machine

-

Model:

-

LKSR-1600B

-

Cutting materials:

-

Corrugated Sheet

-

Max. cutting size(mm):

-

1350x1450

-

Max. paper feeding sizes::

-

1600*1350mm

-

Min. paper feeding size::

-

300*500 mm

-

Power Supply::

-

4.0kw

-

Thickness of feeding paper::

-

1-8mm ( 3-5 layer)

-

Max speed:

-

60

Quick Details

-

Brand Name:

-

LUKES

-

Marketing Type:

-

New Product 2022

-

Type:

-

Rotary Die Cutting Machine

-

Weight (KG):

-

5400 KG

-

Keyword:

-

Semi Automatic Rotary Die Cutting Machine

-

Model:

-

LKSR-1600B

-

Cutting materials:

-

Corrugated Sheet

-

Max. cutting size(mm):

-

1350x1450

-

Max. paper feeding sizes::

-

1600*1350mm

-

Min. paper feeding size::

-

300*500 mm

-

Power Supply::

-

4.0kw

-

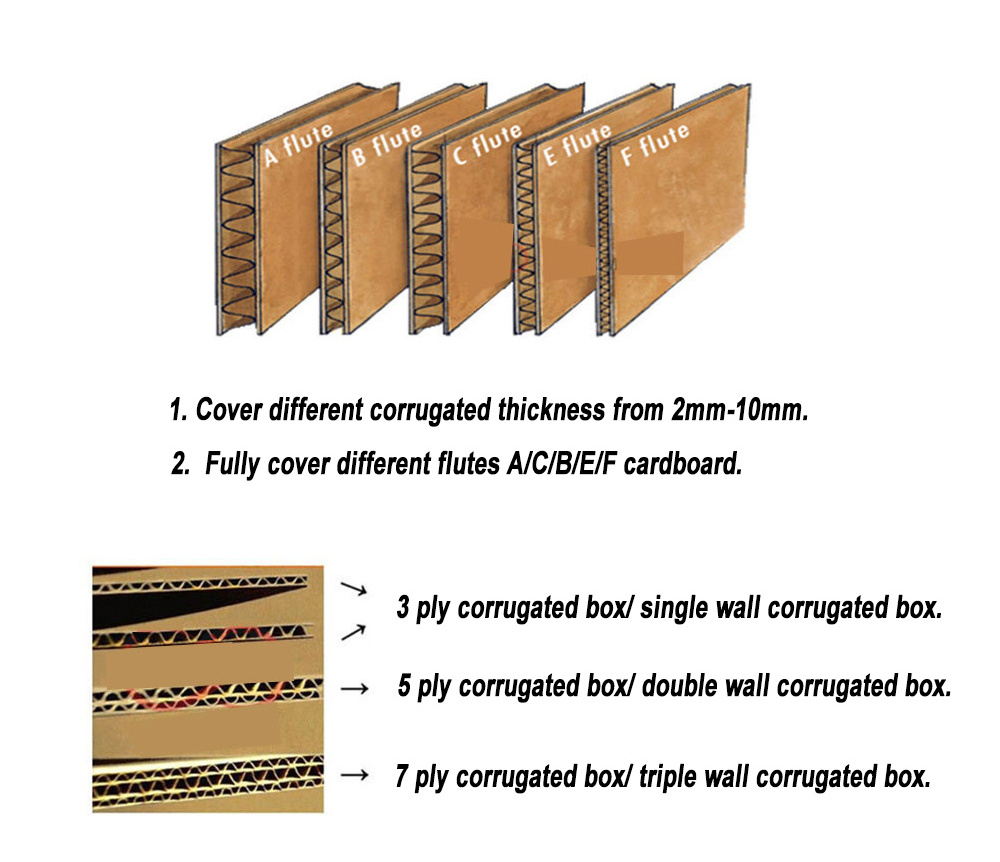

Thickness of feeding paper::

-

1-8mm ( 3-5 layer)

-

Max speed:

-

60

Hot Sales Full auto Corrugated Carton Box Rotary Die Cutting Pizza Box Making Machine With Low Price

Products Description

Corrugated Cardboard Rotary Die Cutting Machine

When the equipment is running, the paper feeding roller sends the cardboard to the middle of the molding plate roller and the pressure roller to cut, and the die cutting cylinder rotated one revolution, is a working cycle.

Product Paramenters

|

Model

|

LKSR-1600B

|

LKSR-1800B

|

LKSR-1800B

|

LKSR-2400B

|

|

Max feeding paper(mm)

|

1600×1350

|

1800×1350

|

2000×1600

|

2400×1600

|

|

Min feeding paper(mm)

|

300×500

|

300×600

|

400×600

|

400×700

|

|

Max. cutting size(mm)

|

1350x1450

|

1350x1750

|

1350x1950

|

1350x2250

|

|

Thickness of feeding paper

|

1-8mm(3-5layers)

|

1-8mm(3-5layers)

|

1-10mm(3-7layers)

|

1-10mm(3-7layers)

|

|

Max speed(pcs/min)

|

60

|

60

|

60

|

60

|

|

Power of main motor

|

4.0KW

|

4.0KW

|

7.5KW

|

7.5KW

|

Chain Feeding Type Rotary Die Cutting Machine:

1.Chain paper feeding mode, double side gear set position, ensure the accuracy of paper feeding.

2.Die

cutting roll 360 degree electric adjustment, digital display, and electronic counter.

3.High frequency processing of the whole gear, spray-type automatic lubrication, greatly improving the operation accuracy and service life.

4.High quality steel, internal tempering, surface grinding, hard chromium plating, and dynamic balance correction, smooth operation.

5.Die cutting rubber cushion imported by CUE Company of the United States is easy to install and change, smooth edge of

die cutting tool, service life can reach 12 million times, greatly reducing production costs.

5.Die cutting rubber cushion imported by CUE Company of the United States is easy to install and change, smooth edge of

die cutting tool, service life can reach 12 million times, greatly reducing production costs.

6.Die cutting rubber cushion roller adopts mechanical transverse moving device, about 40 mm, and controlled by pneumatic device. The tool mould moves up and down to prolong the service life of rubber cushion.

7.Automatic linear velocity compensation, uniform wear and tear of high strength rubber pad, and equipped with rubber pad repair system, rubber pad can be repaired many times.

8. Template free die cutting function can be added.

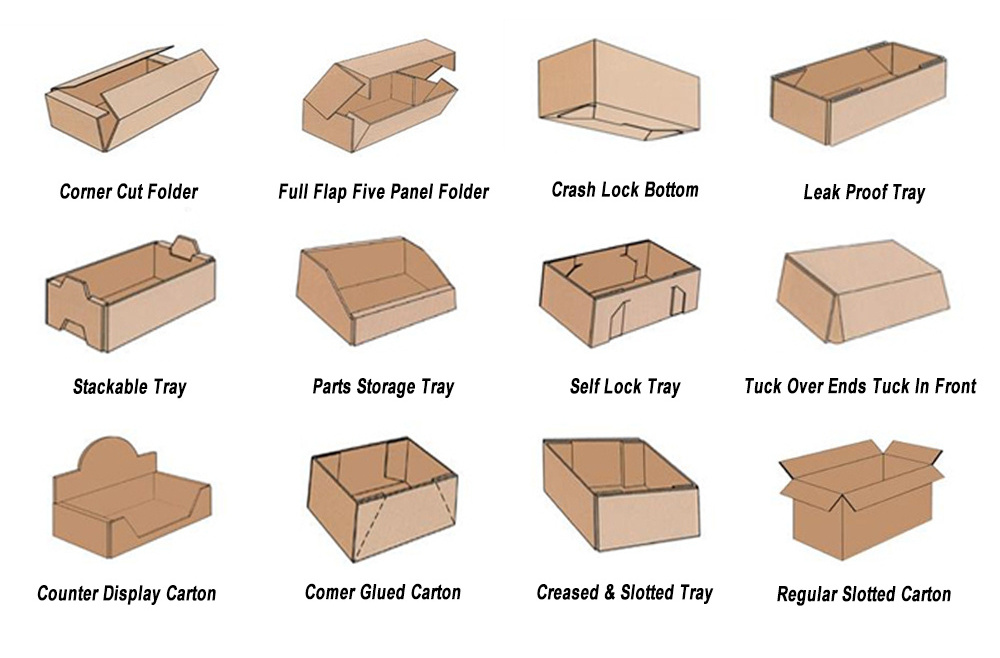

Application

Details Images

Hot Searches