- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customised

-

Dimension(L*W*H):

-

800x940x1460mm

-

Weight (KG):

-

1000

-

Name:

-

Sandblasting Pot

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

KP-0.2-JX

-

Media:

-

cast steel grit

-

Application:

-

Abrasive Blast Rust Cleaning

-

Volume:

-

0.2m3

-

Air Consuming Rate:

-

6.5 m3 /min/single

-

Compressed Air:

-

0.5~0.8mpa

-

Abrasive Media Consuming:

-

1800~2100kg/min/single

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KAiTECH

-

Marketing Type:

-

New Product 2022

-

Power:

-

Customised

-

Dimension(L*W*H):

-

800x940x1460mm

-

Weight (KG):

-

1000

-

Name:

-

Sandblasting Pot

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model:

-

KP-0.2-JX

-

Media:

-

cast steel grit

-

Application:

-

Abrasive Blast Rust Cleaning

-

Volume:

-

0.2m3

-

Air Consuming Rate:

-

6.5 m3 /min/single

-

Compressed Air:

-

0.5~0.8mpa

-

Abrasive Media Consuming:

-

1800~2100kg/min/single

Hot Sale KAiTECH Brand Sandblasting Room/Shot Blasting Machine/Sandblasting Pot

Product Fearure:

1. sand blasting pot is suitable to cleaning workpiece which has comples strucutre, large volume and lots kinds,it can focus on one position, such as oil pipe welding sketch on the sea;

2. Low cost, low investment;

3. Structurer is simple, manufacturering time is short;

4. Low operating cost.

Production Application :

1. Blast cleaning: Used for blast cleaning of casting, die casting,forging,sand removal of casting, steel plate, H type steel, steel structure.

2. Rust removal: Rust removal of casting, forging, steel plate, H type steel, steel structure, descaling of forging.

3. Shot peening: Shot peening of gear, heat treatment.

4. Sand blasting: Shot blasting of profile steel,ship board,steel board,steel material

5. Pretreatment: Pretreatment of surface, steel board, profile steel, steel structure, before painting.

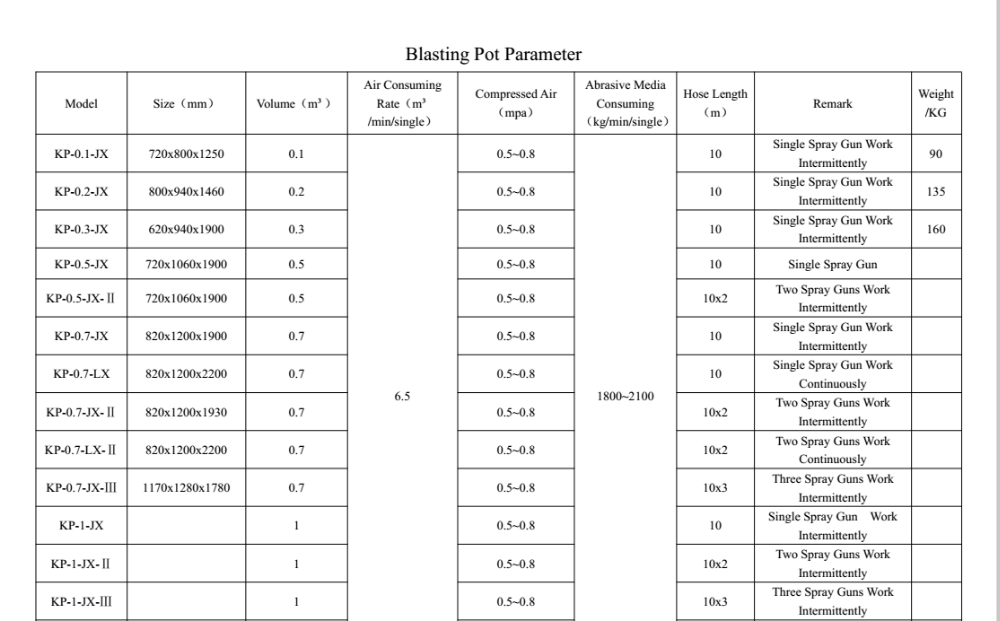

Sand Blasting Pot Parameter:

Standard export package: Machine body with stretch film packaging , pack spare parts , motor ,reducer,etc. into wodden cases , then load into container together.

• Provide comprehensive shot-peening and shot blasting solution

• 20 years experienced engineers provide best proposal for your need.

• Customized design available

• Oversea engineer service avaliable

• To aim to save your cost and improve efficiency

• Offer OEM service.

• One year warranty for machine

• English manual and Video CD for manchine using and maintance.

• Company enjoys high reputation and favorable comments for quality products, good service, and faithful management in past twenty years