- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

65

-

Voltage:

-

AC 220V±10 50/60Hz

-

Current:

-

AC 220V±10 50/60Hz

-

Rated Capacity:

-

AC 220V±10 50/60Hz

-

Rated Duty Cycle:

-

AC 220V±10 50/60Hz

-

Dimensions:

-

L650xW630xH850mm

-

Use:

-

BGA repair

-

Name:

-

BGA Rework Station Repair

-

Power supply:

-

AC 220V±10 50/60Hz

-

Total power:

-

Max 5300W

-

Temperature controlling:

-

high precision K-sensor

-

Locating way:

-

V shape slot

-

PCB size:

-

Min 10x10 mm--Max 450x390mm

-

Applicable chips:

-

Min 1x1 mm--Max 80x80mm

-

Overall dimension:

-

L650xW630xH850mm

-

Temperature Interface:

-

1 pcs

-

Weight of machine:

-

65KG

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

I.C.T

-

Weight (KG):

-

65

-

Voltage:

-

AC 220V±10 50/60Hz

-

Current:

-

AC 220V±10 50/60Hz

-

Rated Capacity:

-

AC 220V±10 50/60Hz

-

Rated Duty Cycle:

-

AC 220V±10 50/60Hz

-

Dimensions:

-

L650xW630xH850mm

-

Use:

-

BGA repair

-

Name:

-

BGA Rework Station Repair

-

Power supply:

-

AC 220V±10 50/60Hz

-

Total power:

-

Max 5300W

-

Temperature controlling:

-

high precision K-sensor

-

Locating way:

-

V shape slot

-

PCB size:

-

Min 10x10 mm--Max 450x390mm

-

Applicable chips:

-

Min 1x1 mm--Max 80x80mm

-

Overall dimension:

-

L650xW630xH850mm

-

Temperature Interface:

-

1 pcs

-

Weight of machine:

-

65KG

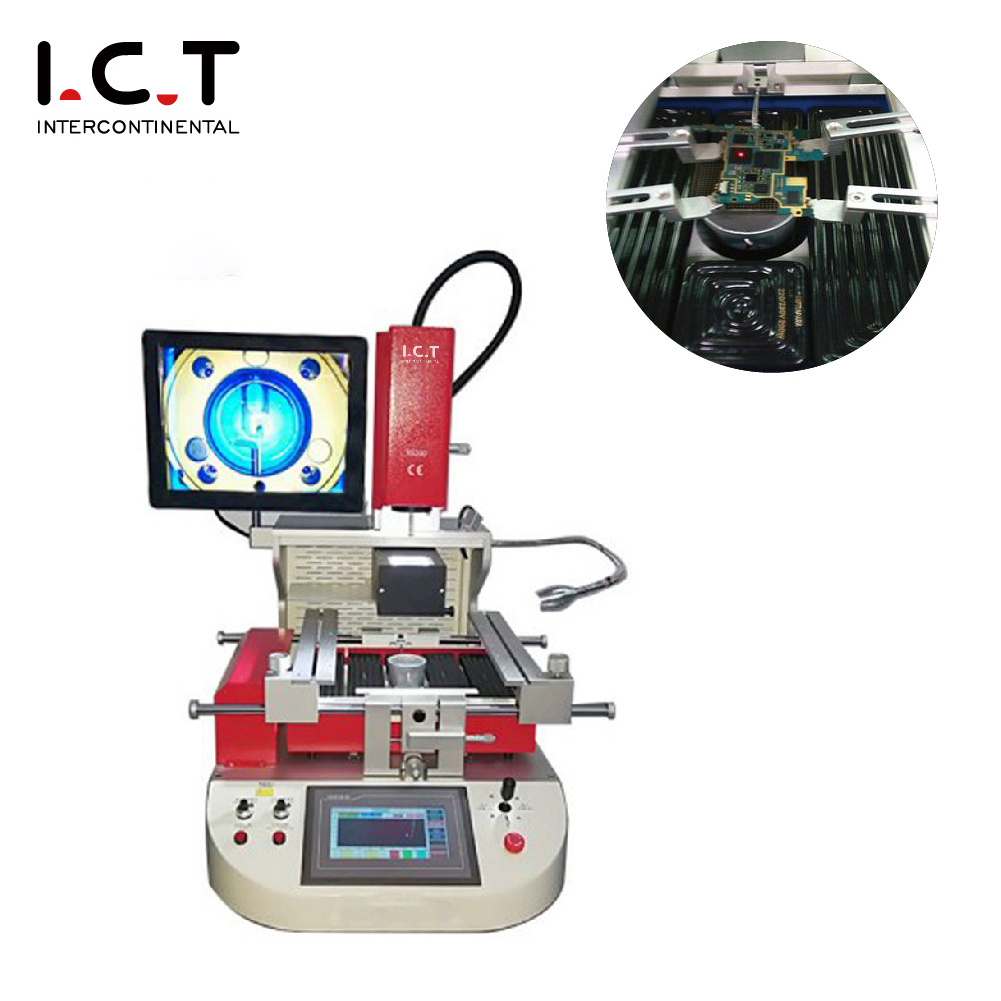

Modern BGA Rework Station Repair BGA Rework Station for Tecno Phones Desoldering BGA Rework Station 2 in 1 Manufacturer

Products Description

I.C.T BGA Rework Station BR120

Features:

A. Independent 3 heating zones temperature control syste

m

1.The upper and lower hot air heating,which can heat up at the same time from the top of he component to the bottom of

the PCB;bottom IR heating,temperature precision control within ±1℃.8 segment temperature control independently.

2.Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and

combine freely the energy of up and lower heating element.

1.The upper and lower hot air heating,which can heat up at the same time from the top of he component to the bottom of

the PCB;bottom IR heating,temperature precision control within ±1℃.8 segment temperature control independently.

2.Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and

combine freely the energy of up and lower heating element.

B. Precision optical alignment system

Using high definition and adjustable CCD color optical alignment system,beam split、amplification、lessening、fine adjustment and auto focus with the function that automatic color aberration resolution and brightness adjustment,adjustable image contrast;equipped with 15 ” high definition LCD monitor.

Using high definition and adjustable CCD color optical alignment system,beam split、amplification、lessening、fine adjustment and auto focus with the function that automatic color aberration resolution and brightness adjustment,adjustable image contrast;equipped with 15 ” high definition LCD monitor.

C. Multi-functional and humanized operation system

Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in 1;providing many

kinds of titanium alloy BGA nozzle can be rotated in 360 degree for easy installation and replacement.

X、Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in 1;providing many

kinds of titanium alloy BGA nozzle can be rotated in 360 degree for easy installation and replacement.

X、Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

D. Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of temperature abuse, the circuit can power off automatically with the double over-temperature protection.Temperature parameter having password

protection to prevent any modification.

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of temperature abuse, the circuit can power off automatically with the double over-temperature protection.Temperature parameter having password

protection to prevent any modification.

Specification :

|

Power supply

|

AC 220V±10% 50/60Hz

|

|

Total power

|

Max 5300W

|

|

Heater power

|

Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 2700W

|

|

Electrical material

|

Driving motor+PLC smart temp.controller+color touch screen

|

|

Temperature controlling

|

high precision K-sensor,Closed Loop,independent temp.controller,the precision can reach ±1℃

|

|

Locating way

|

V shape slot,PCB support jigs can adjust,laser light do fast centering and position

|

|

PCB size

|

Min 10×10 mm--Max 450×390mm

|

|

Applicable chips

|

Min 1×1 mm--Max 80×80mm

|

|

Overall dimension

|

L650×W630×H850mm

|

|

Temperature Interface

|

1 pcs

|

|

Weight of machine

|

65KG

|

|

Color

|

Red ( optional: white/blue)

|

Certifications

Packing & Delivery

※ Standard Wooden Case with Vacuum Package

Shipping Way:

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of electronic industry experience, through our superior resources in China to provide global customers with systematic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customers to set up factories in LED, TV, mobile phone, DVB, EMS and other industries all over the world.

We are trustworthy.

Exhibition

Customers' Feedback

FAQ

|

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner |

|

Q: Are you a trade company or manufacturer?

A: Full SMT machines maufacturer for smt line in China; OEM & ODM service are available. |

|

Q: What is your delivery date?

A: About 35 days after receipt of payment. |

|

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment. |

|

Q: What your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc. |

|

Q: Why choose you?

A: Leading SMT Supplier in China; Professional Supplier on Alibaba; Trade assurance to USD 560,000+; Professional after-sales service team. |

Modern BGA Rework Station Repair BGA Rework Station for Tecno Phones Desoldering BGA Rework Station 2 in 1 Manufacturer

Modern BGA Rework Station Repair BGA Rework Station for Tecno Phones Desoldering BGA Rework Station 2 in 1 Manufacturer

Modern BGA Rework Station Repair BGA Rework Station for Tecno Phones Desoldering BGA Rework Station 2 in 1 Manufacturer

Hot Searches