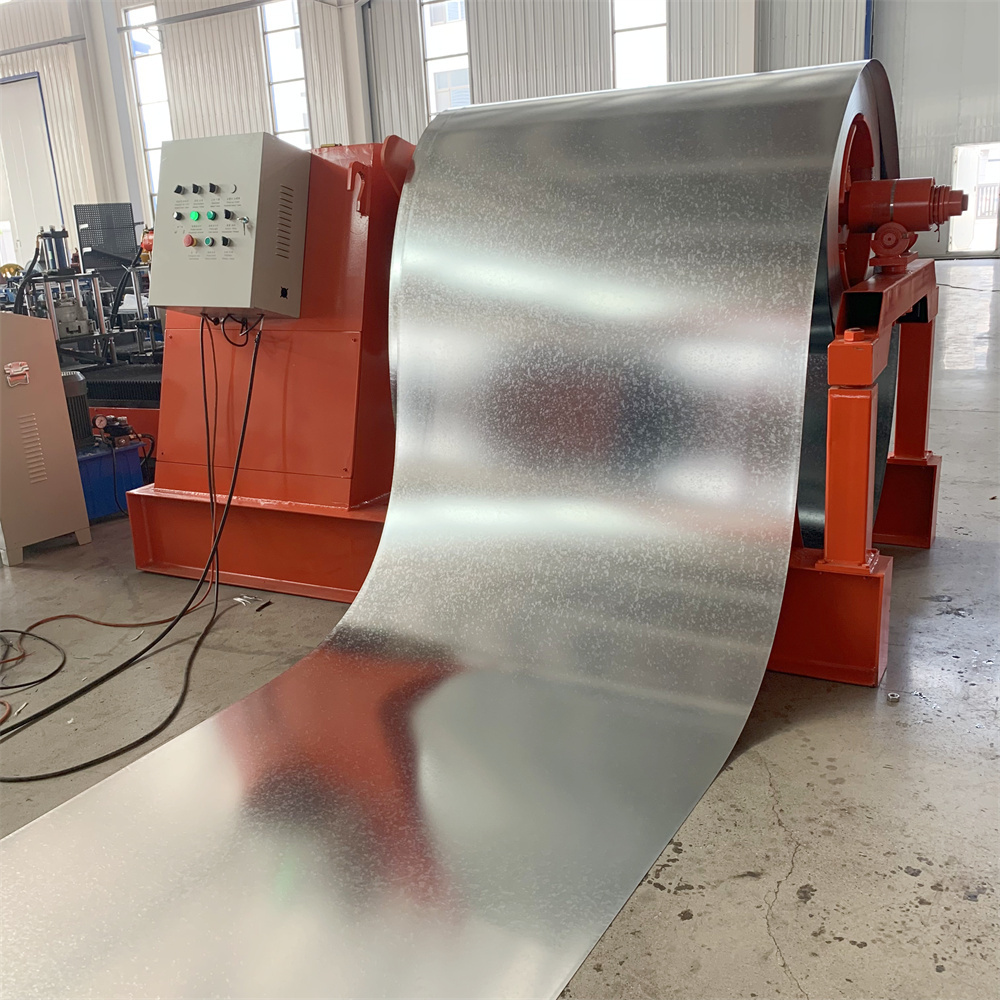

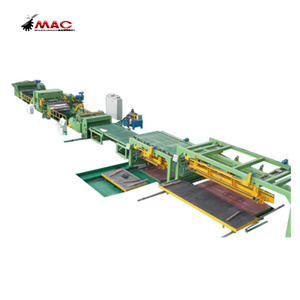

Hydraulic system expand coil inner hole,Dual oil cylinder, cylinder diameter 90mm, stroke 240mmm,

Car travel: height travel 400mm, length travel 2.5m, Frequency Inverter to regulate turning speed Link-connect expanding system,Coil Inner-Diameter:450-510mm,

Coil width:1000-1650mm, Automatic stopping device with limited switch as assistance to control stop/start rotation

Car travel: height travel 400mm, length travel 2.5m, Frequency Inverter to regulate turning speed Link-connect expanding system,Coil Inner-Diameter:450-510mm,

Coil width:1000-1650mm, Automatic stopping device with limited switch as assistance to control stop/start rotation