- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

12.5kg

-

Flux Content:

-

2%

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HengTai

-

Model Number:

-

ER CuNiAl

-

Application:

-

International Standard

-

Product name:

-

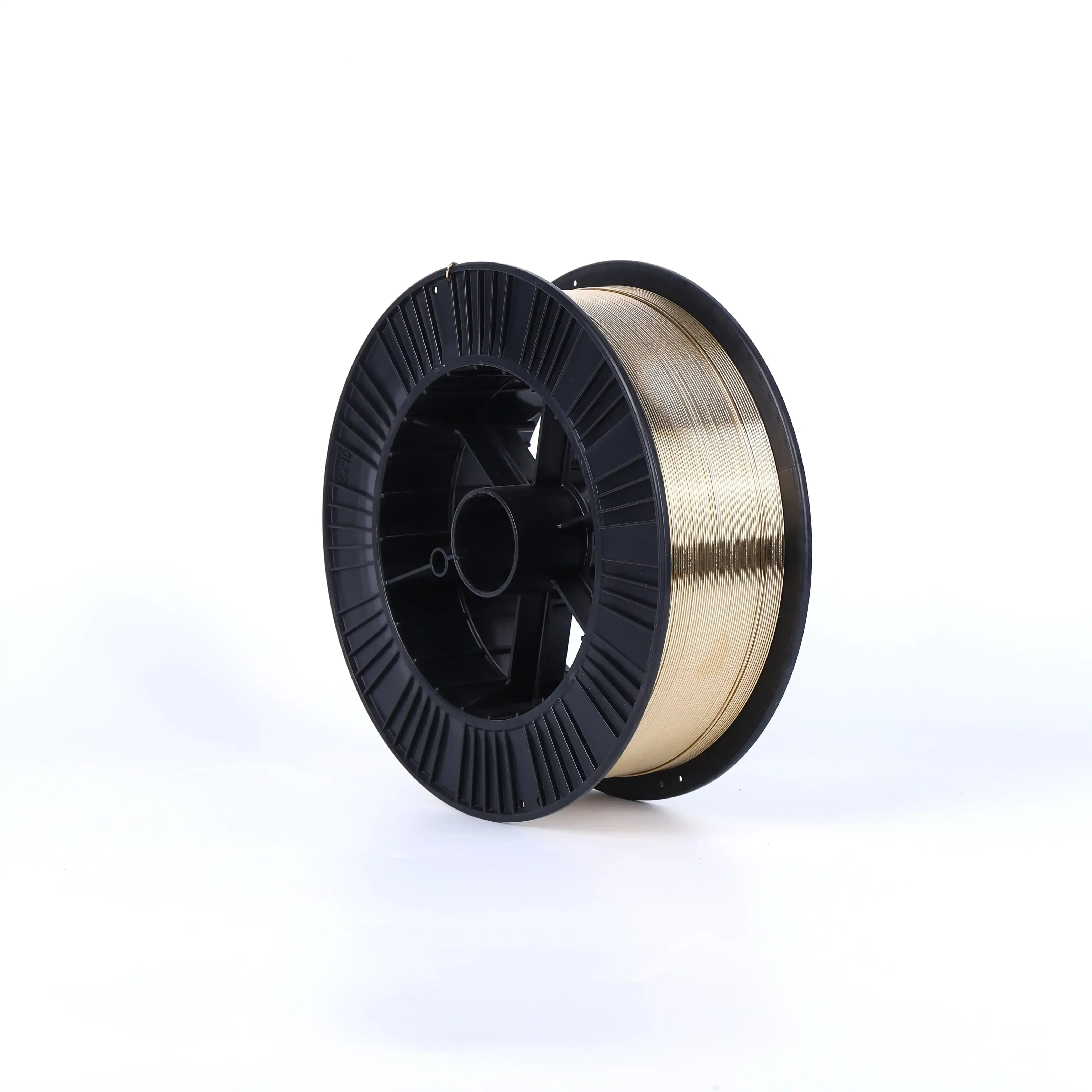

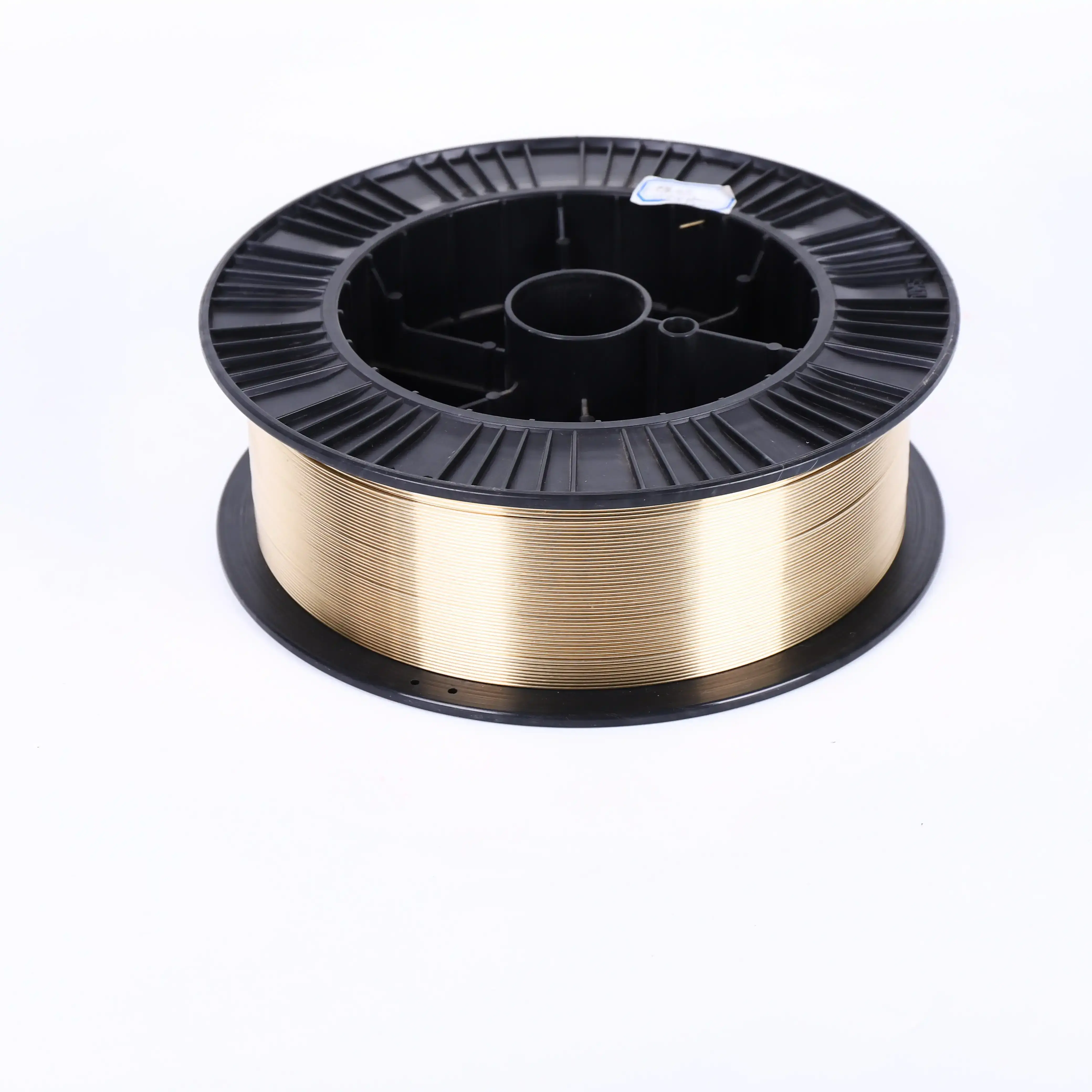

Aluminum Bronze Alloy MIG Welding Wire

-

Feature:

-

Excellent Welding Performance

-

OEM:

-

Accept

-

MOQ:

-

500kg

-

Sample:

-

Avaiable

-

Packing:

-

1Kg /5Kg/10Kg/15Kg/20Kg

-

Spool materials:

-

Plasitc

Quick Details

-

Material:

-

Copper / Copper Alloy

-

Diameter:

-

MIG 0.8-2.0mm TIG 1.6-6.4mm

-

Melting Point:

-

1045°C

-

Weight:

-

12.5kg

-

Flux Content:

-

2%

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HengTai

-

Model Number:

-

ER CuNiAl

-

Application:

-

International Standard

-

Product name:

-

Aluminum Bronze Alloy MIG Welding Wire

-

Feature:

-

Excellent Welding Performance

-

OEM:

-

Accept

-

MOQ:

-

500kg

-

Sample:

-

Avaiable

-

Packing:

-

1Kg /5Kg/10Kg/15Kg/20Kg

-

Spool materials:

-

Plasitc

PRODUCTS DESCRIPTION

|

Physical Properties and Mechanical Properties

|

|

|

|

Solids-Temperature

|

1030℃

|

|

|

Liquids-Temperature

|

1054℃

|

|

|

Density

|

7.5kg/dm²

|

|

|

Tensity Strength

|

430~540N/mm³

|

|

|

Elongation

|

30%

|

|

|

Brinell Hardness

|

130~150HB

|

|

Introduction

Recommended for the welding and hard facing of copper-aluminum alloys, aluminum coated steel in machinery and chemical industry as well as for iron weldng in shipbuilding. Also excellet for the weldingof brass tube and copper-aluminum that requires resistance to erosion.

PACKING DETAILS

A spool in a carton box

Can be customized according to customer needs

1000kgs inner a wooden case

Can be customized according to customer needs

Loading and transporting to the port.

Can be customized according to customer needs

ABOUT US

Anhui Hengtai Welding Materials Co., Ltd. which was founded in 2007, is a professional manufacturer of copper and copper alloy welding materials.

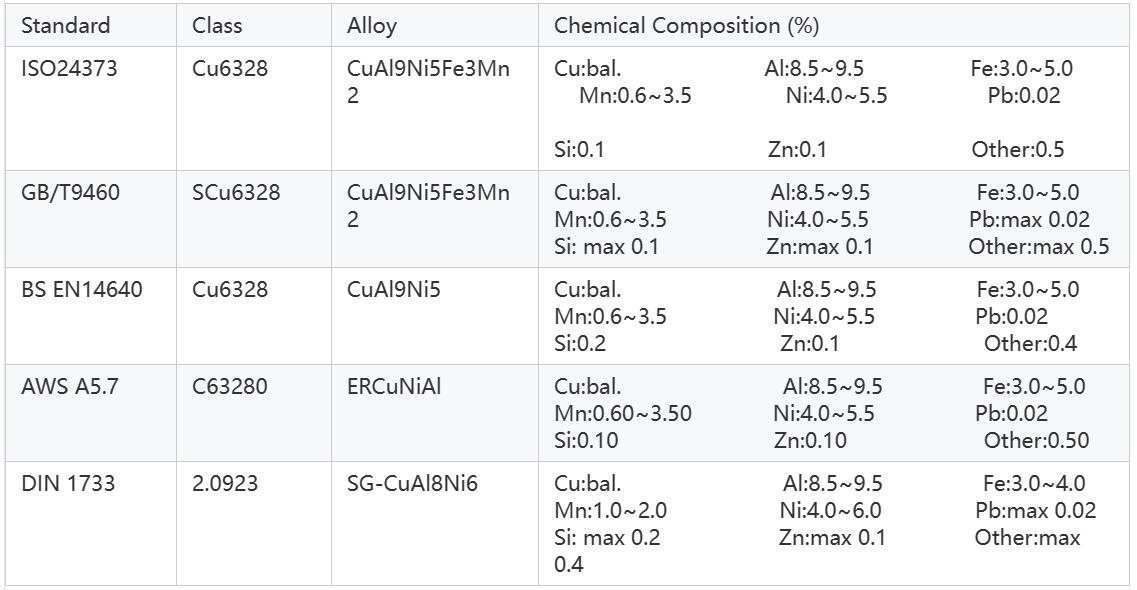

Company adopted GB/T9460, BS EN14640, AWS, DIN standards,the production of copper, silicon bronze, aluminum bronze, tin bronze, white copper, brass, copper alloy series welding materials, and is widely used in automobiles, ships, engineering machinery, metallurgy, electric power,aviation,aerospace, oil and other fields. With years of communication with the majority of users and accumulated experience, the company provides each customerwith high-quality, reliable copper alloy series service,welding materials and thoughtful anddetailed pre-sale and after-sales “integrity-based, win-win cooperation” is the company’s corporate culture and purpose, we will cast a common dream with the spirit of craftsmen.

Company adopted GB/T9460, BS EN14640, AWS, DIN standards,the production of copper, silicon bronze, aluminum bronze, tin bronze, white copper, brass, copper alloy series welding materials, and is widely used in automobiles, ships, engineering machinery, metallurgy, electric power,aviation,aerospace, oil and other fields. With years of communication with the majority of users and accumulated experience, the company provides each customerwith high-quality, reliable copper alloy series service,welding materials and thoughtful anddetailed pre-sale and after-sales “integrity-based, win-win cooperation” is the company’s corporate culture and purpose, we will cast a common dream with the spirit of craftsmen.

RELATED PRODUCTS

Copper Welding Wire CuSn1 ERCu, for cast iron and nickel alloys

Copper alloy welding wire ERCuAl-A1 Aluminum Bronze

Silicon Bronze Welding rod TIG ERCuSi-A for argon arc welding

Factory sales Tin Brass welding rod RBCuZn-A HS221

Deoxidized copper welding rod ERCu CuSn1 C18980

PRODUCTS APLLICATION

Our products are suitable for automobile casting, high pressure valve iron, hydraulic rod, marice casting, aerospace casting, ocean exploration, precision machinery, deep sea scale, marine water scale, high pressure valve, etc. Our company is a world leader in the field of copper alloys, and has made outstanding contributions to the field of copper alloy welding in the world. Our company has been to Arabia, Dubai, Germany, the United States, France, the Middle East, and Vietnam for many times to conduct academic exchanges and promote the world. Development in the field of copper alloy welding.

FAQ

Hot Searches