- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULLWIN

-

Voltage:

-

depend on customer

-

Dimension(L*W*H):

-

depend on design

-

Power (kW):

-

60

-

Weight:

-

KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PP PE Granules

-

Usage:

-

cable pipe

-

Product:

-

corrugated pipe

-

Capacity:

-

45-65kg/h

-

Extruder:

-

Single Screw Extruder

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Screw type:

-

Single-screw Screw

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FULLWIN

-

Voltage:

-

depend on customer

-

Dimension(L*W*H):

-

depend on design

-

Power (kW):

-

60

-

Weight:

-

KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PP PE Granules

-

Usage:

-

cable pipe

-

Product:

-

corrugated pipe

-

Capacity:

-

45-65kg/h

-

Extruder:

-

Single Screw Extruder

-

Color:

-

Customer Choice

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Screw type:

-

Single-screw Screw

Products Description

Single wall corrugated pipe extrus

io

n

line

FULLWIN series of plastic single wall corrugated pipe production line meticulously developed by our company, through the gear drive mould,water cooling in the water trough of the forming machine,the products are air-cooled,so that production of the corrugated pipe molding speed,uniform corrugated shape, smooth inside and outside the wall.

|

Equipment List

|

|

|

||

|

1

|

Auto feeder and Vacuum hopper loader

|

1 set

|

||

|

2

|

SJ65/30 Single screw extruder machine

|

1 set

|

||

|

3

|

Die head

|

1 set

|

||

|

4

|

Water cooling forming machine

|

1 set

|

||

|

5

|

Double station winder

|

1 set

|

||

|

6

|

Forming mould

|

1 set

|

||

Send inquiry to get price and more details of machine!☞

Extruder machine

Using high quality screw, uniform heating and plasticizing

Die head

When changing the size, we only need to change the whole, and there is no need to clean the waste inside.

Water cooling pipe forming machine

High speed forming machine with large water cooling plate,m

ake the pipes cool faster and form more beautiful shapes

the mould with double chamber design,

when change size just up and down move forming machine. No need to unmount and reinstall. So will save more than two hours

Double station winder

Automatically adjust the speed for uniform winding, pneumatic unwinding

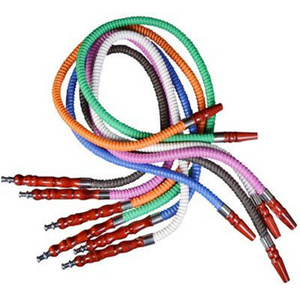

Final Product

Customer feedback

Contact us

Packing and delivery

Why Choose Us

Our advantage:

1、More than 15+ years plastic extrusion production experience and design experience.

1、More than 15+ years plastic extrusion production experience and design experience.

2、

35+

design patents ,

CE,ISO

certificate.

3、Until now has 3 factories have been built and running, and have 2 factories are still building ,Workshop area

10000㎡.

4、Professional international trade sales team and after-sales service team,extremely fast response rate as high as 99%.

5、Overseas office and overseas engineer, can provide

door-to-door

service.

Hot Searches