- Product Details

- {{item.text}}

Quick Details

-

Ejector Number:

-

1+4

-

Ejector Stroke(mm):

-

130 mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

188 cm³

-

Injection Rate (g/s):

-

106 g/s

-

Injection Weight (g):

-

171 g

-

Screw Speed (rpm):

-

1 - 210 rpm

-

Screw diameter (mm):

-

36 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

465x418

-

Weight (KG):

-

4300 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

430 mm

-

Model Number:

-

SK140A

-

Brand Name:

-

SUNBUN

-

Power (kW):

-

14 kW

-

Marketing Type:

-

New Product 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

465mm

-

Distance between Tie Bars(Height)(mm):

-

418mm

-

Mold Height(mm):

-

180 - 460 mm

-

Ejector Number:

-

1+4

-

Ejector Stroke(mm):

-

130 mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

188 cm³

-

Injection Rate (g/s):

-

106 g/s

-

Injection Weight (g):

-

171 g

-

Screw Speed (rpm):

-

1 - 210 rpm

-

Screw diameter (mm):

-

36 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

465x418

-

Weight (KG):

-

4300 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

430 mm

-

Model Number:

-

SK140A

-

Brand Name:

-

SUNBUN

-

Power (kW):

-

14 kW

-

Marketing Type:

-

New Product 2021

Product Description

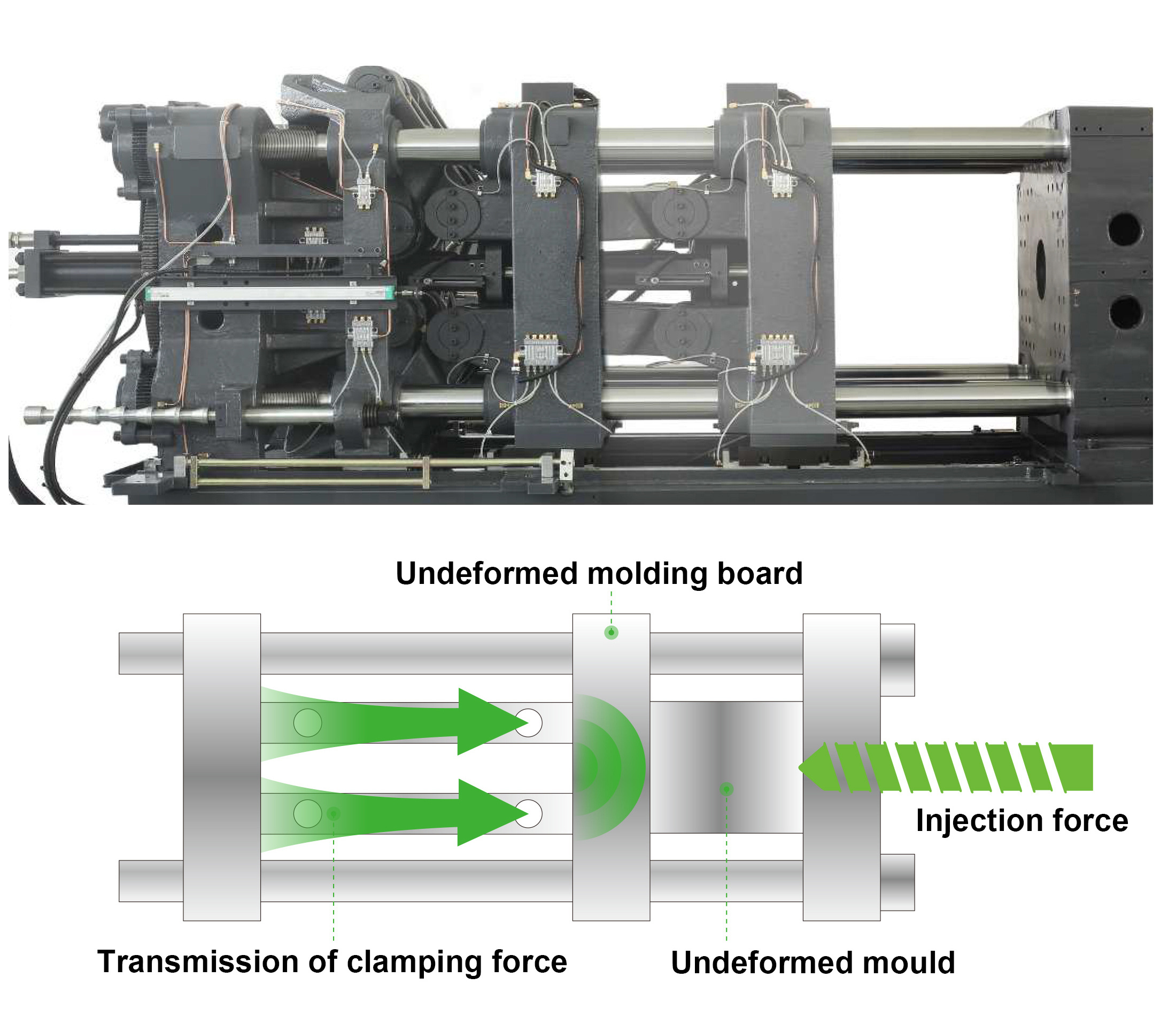

SK SERIES MECHANICAL VERTICAL-COMPRESSION STRUCTURE

Resilient mould thickness and long displacement stroke

Reasonable oil circuit design, which is more energy-saving,

improves the operating speed and can save 2%-6% raw

materials from 90% products for the customers.

improves the operating speed and can save 2%-6% raw

materials from 90% products for the customers.

Reinforced molding board, thicker pull rod, high rigidity frame, with more stable operation state and longer service life.

TRADITIONAL STRUCTURE

Mechanical Vertical-Compression Structure Applied by Sunbun Injection Molding Machine

1.100% clamping use ratio, 10%-20% higher than that of traditional structures;

2. Less fins on the finished products;

3. 2%-6% raw materials saved from production than that of traditional structures;

4. Effective protection for the mould, molding board, and pull rod;

5. A opening stroke 10%-20% longer than that of traditional structures;

6. Less deformation caused by cooling of the products.

2. Less fins on the finished products;

3. 2%-6% raw materials saved from production than that of traditional structures;

4. Effective protection for the mould, molding board, and pull rod;

5. A opening stroke 10%-20% longer than that of traditional structures;

6. Less deformation caused by cooling of the products.

Specification

|

Injection Part

|

Item/type

|

Unit

|

SK140 / C400

|

|

|

||

|

|

Screw type

|

|

A

|

B

|

C

|

||

|

|

Screw diameter

|

mm

|

36

|

40

|

45

|

||

|

|

Screw diame-ter ratio

|

L/D

|

22

|

22

|

20

|

||

|

|

Theoretical injection volume

|

cm³

|

188

|

232

|

294

|

||

|

|

Injection volume (PS)

|

g

|

171

|

211

|

267

|

||

|

|

Maximum rate for inject-ion to air

|

cm³/s

|

106

|

131

|

166

|

||

|

|

Injection pressure

|

MPa

|

210

|

171

|

135

|

||

|

|

Injection stroke

|

mm

|

185

|

|

|

||

|

|

Maximum injection speed

|

mm/s

|

105

|

|

|

||

|

|

Maximal Rotational Speed of Screw

|

r/min

|

210

|

|

|

||

|

Clamping Part

|

Clamp Tonnage

|

KN

|

1400

|

|

|

||

|

|

Toggle stroke

|

mm

|

430

|

|

|

||

|

|

Distance between tie bars

|

mmxmm

|

465x418

|

|

|

||

|

|

Maximum mould height

|

mm

|

460

|

|

|

||

|

|

Minimum mould height

|

mm

|

180

|

|

|

||

|

|

Ejection stroke

|

mm

|

130

|

|

|

||

|

|

Ejector force forward

|

KN

|

45

|

|

|

||

|

|

Ejector force backard

|

KN

|

30

|

|

|

||

|

|

Amount of die thimble

|

Pcs

|

1+4

|

|

|

||

|

|

System pressure

|

Mpa

|

17.5

|

|

|

||

|

|

Motor power

|

KW

|

14

|

|

|

||

|

|

Heater power

|

KW

|

8.2/8.55

|

|

|

||

|

|

Quantity of temperature-control zones

|

|

1+4

|

|

|

||

|

|

Bucket capacity

|

KG

|

25

|

|

|

||

|

|

Oil tank capacity

|

L

|

185

|

|

|

||

|

|

Boundary dimension(L×W×H)

|

m

|

5x1.4x1.8

|

|

|

||

|

|

Machine weight

|

Ton

|

4.3

|

|

|

||

INJECTION SYSTEM

CLAMPING SYSTEM

HYDRAULIC SYSTEM

ELECTRONIC CONTROL SYSTEM

Application

Auto parts

Sanitation products

Medical field

Black and white household appliance

Toy industry

Home appliances

Powder box

Lipstick

Shoes material products

Packing & Delivery

Hot Searches