- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CP-MV66010

-

Brand Name:

-

COMPASS

-

Product name:

-

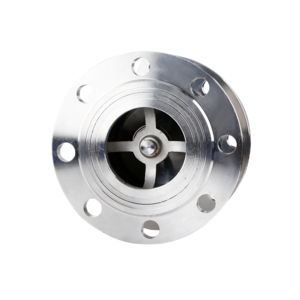

Sanitary Mixproof Valve

-

Material:

-

SS304/SS316L

-

Connection:

-

Clamp, Weld, Threaded, union

-

Material pressure range:

-

0-8bar

-

Size:

-

DN40-DN100,1.5"-4"

-

Temperature range:

-

-10C°-150C

-

Gasket:

-

EPDM, Silicone,FKM

-

External:

-

sandblasting or matte polishing Ra≤0.6um

-

Internal:

-

polished Ra≤0.6um

Quick Details

-

Port Size:

-

DN40-DN100,1.5"-4"

-

Warranty:

-

1 years

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

CP-MV66010

-

Brand Name:

-

COMPASS

-

Product name:

-

Sanitary Mixproof Valve

-

Material:

-

SS304/SS316L

-

Connection:

-

Clamp, Weld, Threaded, union

-

Material pressure range:

-

0-8bar

-

Size:

-

DN40-DN100,1.5"-4"

-

Temperature range:

-

-10C°-150C

-

Gasket:

-

EPDM, Silicone,FKM

-

External:

-

sandblasting or matte polishing Ra≤0.6um

-

Internal:

-

polished Ra≤0.6um

Product Despription

DN40 Hygienic Sanitary Control Stainless Steel Valves Price Mixproof Mix Proof Valve

Anti-mixing separation is carried out for non-mixable media at the intersection of flow channels. In the closed position of the valve, there is a double seal between the two pipelines. The phenomenon of liquid leakage from one pipeline to the other can be completely ruled out. When the sealing part is damaged Yes, the leakage can be discharged to the outside through the leakage chamber of the valve. With a separate CIP connection, the washing liquid is supplied to the isolation chamber. The cleaning of the isolation chamber is independent of the position of the valve.

Specification

|

Product Name

|

Sanitary Pneumatic Unique Mixproof valve

|

|

|

|

||||

|

Body Material

|

SS304/SS316

|

|

|

|

||||

|

Surface treatment

|

Ra<0.8μm.

|

|

|

|

||||

|

Seat Material

|

Silicone, EPDM, FKM

|

|

|

|

||||

|

Connection method

|

Clamped, Threaded, Welded, Flanged

|

|

|

|

||||

|

Size

|

1.5"-4", other size can be customized

|

|

|

|

||||

|

Norms

|

DIN/SMS/3A/ISO/IDF/RJT/BPE/DANSK

|

|

|

|

||||

|

Max Pressure

|

8 bar

|

|

|

|

||||

|

Application

|

Food, beverage, dairy, chemical, pharmaceutical fields, etc

|

|

|

|

||||

|

|

|

|

|

|||||

Material

The part of the product in contact with the medium: 304 or 316L

Parts of the product not in contact with the medium: 304

Sealing ring: EPDM, silicone, fluorine rubber, etc.

Advantage:

Reduced number of parts

small footprint

Easy to maintain

no dead ends

Discharge system does not come into contact with product

The cleaning of the isolation chamber does not generate hydraulic pressure, and the cleaning is not affected by the status of the equipment and the opening/closing status of the valve

Surface treatment

External: sandblasting or matte polishing Ra≤0.6um

Internal: polished Ra≤0.6um

Technical Parameters

Material pressure range: 0-8bar

Temperature range: -10C°-150C°

Operating air pressure: 6-8bar

Actuator Quality Requirements

Compressed air connection: air pipe with air connector R1/8"

Maximum particle size: 0.01um

Maximum oil content: 0.08ppm

Dew point: 10° or less below atmospheric temperature

Maximum water content: 7.5g/kg

The anti-mixing valve can be combined into an anti-mixing valve array, and the anti-mixing valve array can realize safe, efficient and hygienic logistics and transportation operations; this is better in occasions that require frequent switching of logistics channels and require high safety and sanitation application

-----------Related

Mixproof Valve

Products-----------

-------------- Application------------------

Food, beverage, dairy, chemical, pharmaceutical fields, etc

Contact Us

Hot Searches