- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Super Fine Screen Cleaner

-

Use:

-

Various Seeds Cleaning

-

Applicable Industries:

-

fine seed cleaning machines

-

Key Selling Points:

-

fine seed cleaning machines

-

Production Capacity (kg/h):

-

100 - 12000

-

Sieve Size(mm):

-

1250*800mm

-

Marketing Type:

-

fine seed cleaning machines

-

Power (kW):

-

14.2

-

Weight:

-

3120 KG

-

Other Name:

-

Super Fine Screen Cleaner

-

Application:

-

Wheat Corn Paddy Soy Grain Seed Cleaning

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AYSC

-

Dimension(L*W*H):

-

3.2*1.9m*3.6m

-

Type:

-

Super Fine Screen Cleaner

-

Use:

-

Various Seeds Cleaning

-

Applicable Industries:

-

fine seed cleaning machines

-

Key Selling Points:

-

fine seed cleaning machines

-

Production Capacity (kg/h):

-

100 - 12000

-

Sieve Size(mm):

-

1250*800mm

-

Marketing Type:

-

fine seed cleaning machines

-

Power (kW):

-

14.2

-

Weight:

-

3120 KG

-

Other Name:

-

Super Fine Screen Cleaner

-

Application:

-

Wheat Corn Paddy Soy Grain Seed Cleaning

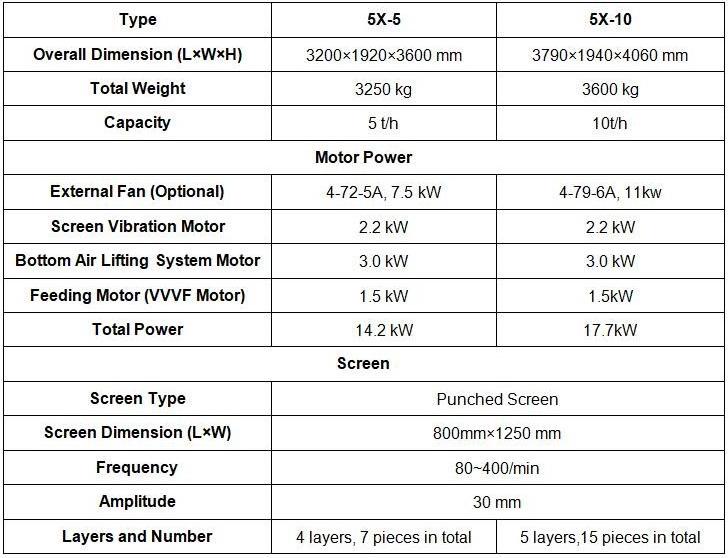

Screen Cleaner

is one of the main equipment in seeds cleaning line.

It is suitable for cleaning all kinds of grains and seeds.

Other name: Grain and Seed Delta Super Fine Screen Cleaner

Features

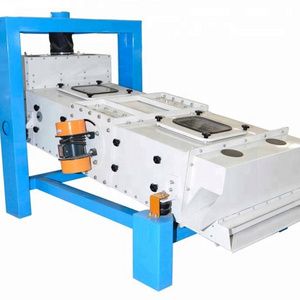

- It includes feeding system, pre-suction and after-suction system, electronic control system, flexible screen flow and air lifting fan.

- Sophisticated feeding system makes sure materials uniform feeding across the entire working screen width.

- It is equipped with two air separation systems. The pre-suction is designed to remove dust and light foreign materials at inlet of the machine. The after-suction system is designed to collect remaining husks at the final outlet of the machine.

- All Motors are with integrated frequency control to reach optimal cleaning effect.

- All screens are interchangeable for different cleaning requirements.

- Flexible installation and low noise thanks for whole machine body complete symmetrical design in left and right.

- With rubber balls below each screen to avoid any possible blocking

- The airlifting system provides a positive air flow from below the materials together with the negative air from the after-suction system making one harmonious air flow system to reach the most precise grain cleaning result.

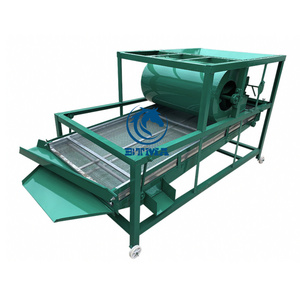

Technical Data