- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

nitinol wire

-

Grade:

-

Nickel Titanium Alloy

-

Ti (Min):

-

45

-

Strength:

-

1300

-

Wire Gauge:

-

0.08~7.0 mm

-

Wires:

-

0.08~7.0 mm

-

Standard:

-

ASTM F2063

-

Color:

-

Polished, ground, oxide surface

-

Surface Treatment:

-

hydrogen annealing

-

Shape:

-

wire, coil, rod

-

Resistance tolerance:

-

±3%

-

Certificatte:

-

CE, ISO 9001

-

OEM:

-

accept

-

Sample:

-

avaiable

-

Mill test report:

-

avaiable

Quick Details

-

Application:

-

Medical

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SZNK

-

Model Number:

-

nitinol wire

-

Grade:

-

Nickel Titanium Alloy

-

Ti (Min):

-

45

-

Strength:

-

1300

-

Wire Gauge:

-

0.08~7.0 mm

-

Wires:

-

0.08~7.0 mm

-

Standard:

-

ASTM F2063

-

Color:

-

Polished, ground, oxide surface

-

Surface Treatment:

-

hydrogen annealing

-

Shape:

-

wire, coil, rod

-

Resistance tolerance:

-

±3%

-

Certificatte:

-

CE, ISO 9001

-

OEM:

-

accept

-

Sample:

-

avaiable

-

Mill test report:

-

avaiable

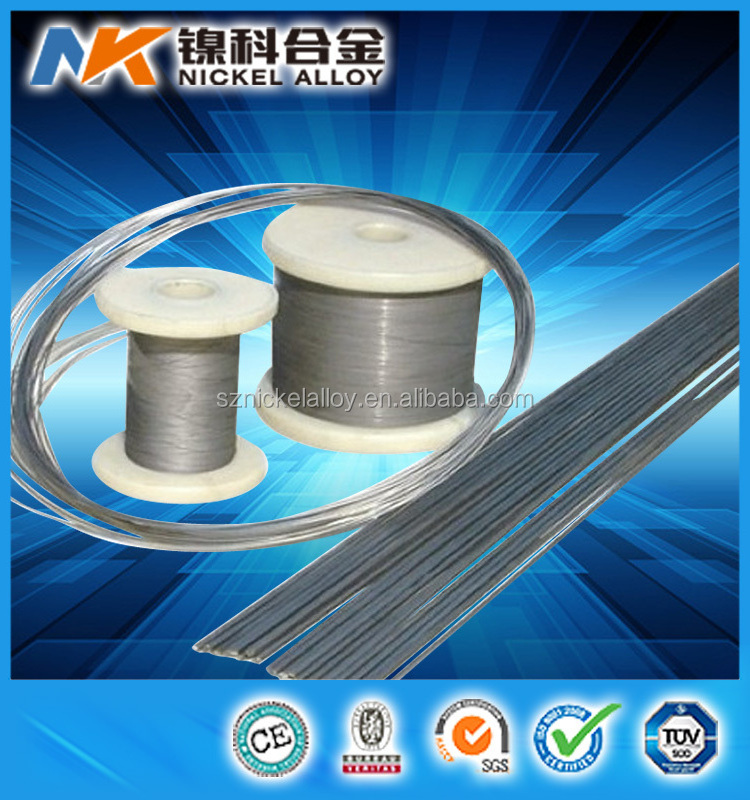

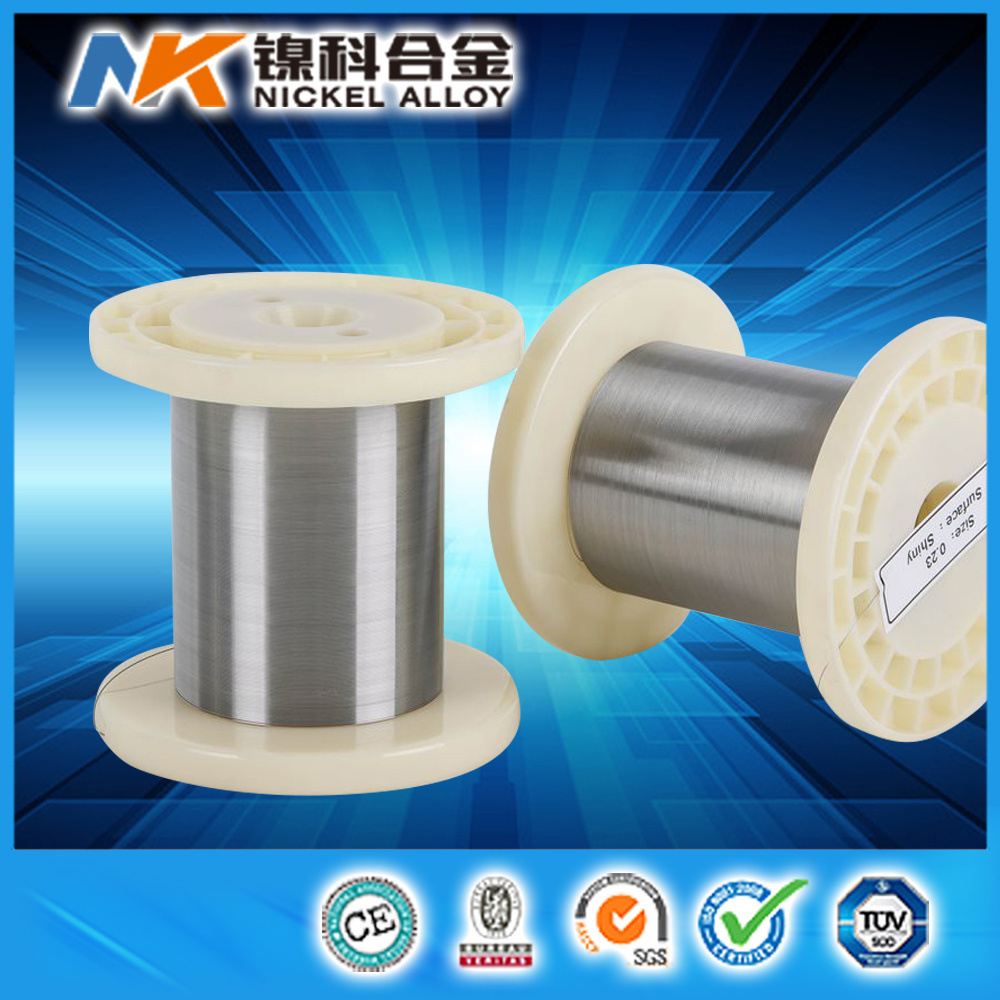

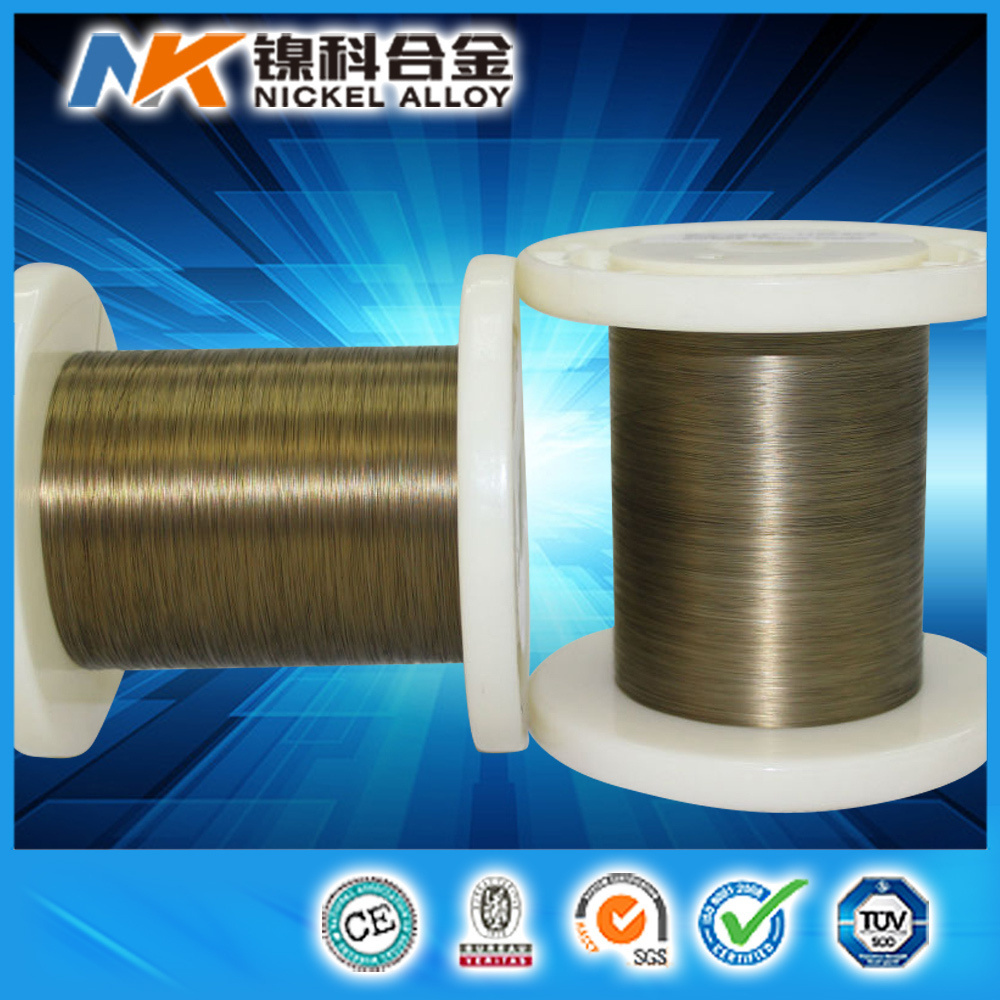

nitinol wire

Grade: Nitinol alloy

Spool from flange to flange

Long life service

ISO certificate

Best price medical niti guide wire superelastic nitinol wire

Superelastic Nitinol Alloys / Shape memory Nitinol alloys / Nitinol Memory Wire

Nickel Titanium (also known as Nitinol or NiTi ) is in the unique class of shape memory alloys. A thermoelastic martensitic

phase transformation in the material is responsible for its extraordinary properties. Nitinol alloys are typically made of 55%-56%

Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material. There are t

wo primary categories of Nitinol. The first, known as "SuperElastic", is characterized by extraordinary recoverable strains and

kink resistance. The second category, "Shape Memory" alloys, is valued for the Nitinol's capacity to recover a pre-set shape

when heated above its transformation temprature. The first category is often used for orthodontics (braces, wires, etc) and

eyeglasses. SZNK makes shape memory alloys, which are primarily useful for actuators, used in many different mechanical

devices.

Nitinol Materials

• Our nitinol material products include nitinol wires , nitinol tubing , and shapeset nitinol components

• Chemical composition: Reference ASTM F2063-2012 or GB 24627-2009;

• Af temperature range: -40C~85C

Nitinol Wire

· Diameter Range: OD0.08mm~OD7.00mm

· Surface State Options:

• Oxide surface(including Black oxide, Blue oxide, Amber oxide)

• Etched surface

• Polished surface

• Ground surface

· Tolerances:

4.000~2.000mm ±0.020mm

2.000~1.000mm ±0.015mm

1.000~0.350mm ±0.010mm

0.350~0.260mm ±0.007mm

0.260~0.150mm ±0.005mm

0.150~0.080mm ± 0.004mm

Standard: ASTM F2063-05 Q/XB1516 Customer specified or Industry Standard

Nitinol wire Specifications

|

Alloy |

Chemical composition |

Af (Fully annealed) |

Min. elongation to failure [%] |

Max. Residual elongation after 6% strain [%] |

Main Applications |

Specifications |

|

|

Superelastic Ni-Ti alloy |

TiNi-SS |

Ti-50.8at% |

-5°C ± 5°C. |

10 |

0.1 |

Eyeglass Frames, Cellular Phone Antennae, Bra Underwire |

Q/XB1516.2 Q/XB1516.2 |

|

TN3 TNC |

TiNiVAl TiNiCr |

-40°C ~50°C |

10 |

0.1 |

|||

|

Body temperature Ni-Ti alloy |

TiNi-YY |

Ti-50.7at%Ni |

Functional Af=33 ± 3 |

15 |

0.1 |

Implantable devices, Bone staples Vascular Stents |

ASTM 2063 |

|

Ti-Ni-01 |

55.6~55.8 wt%Ni |

20 - 40 |

15 |

0.1 |

Guide wires, Stents Orthodontic Arches |

Q/XB1516.1 |

|

|

High temperature Ni-Ti alloy |

Ti-Ni-02 |

54.8~55.5wt%Ni |

45 - 95 |

10 |

0.1 |

Implantable active devices, Surgical tools, Thermostats Coffeepots |

Q/XB1516.1 |

|

TiNiCu |

TiNiCu |

As-Ms ≤ 5 |

10 |

0.1 |

|||

Nitinol wire alloy code:

Regular binary NiTi alloy code, main composition, and typical active Af temperature (per ASTM F2063-05 or GB 24627-2009)

*The real active Af temperature may varies with actual composition, thermo-mechanical history of the products.

|

Alloy code |

A |

B |

S |

C |

D |

E |

|

Main composition mass%Ni |

55.07 |

55.66 |

55.76 |

55.86 |

55.96 |

56.25 |

|

*Active Af after heat treatment, °C |

75+/-5 |

28+/-5 |

23+/-5 |

11+/-5 |

5+/-5 |

-15+/-5 |

Regular ternary NiTi alloy code, main composition, and typical active Af temperature

|

Alloy code |

F |

G |

I |

J |

H |

|

Main composition mass%Ni |

44.0Ti

|

44.0Ti

|

50.0Ti

|

50.0Ti

|

47.0Ni

|

|

*Active Af after heat treatment, °C |

Similar to binary Nitinol D with higher strength |

Similar to ternary NiTi0.2Cr with higher strength |

42+/-5 |

-32+/-6 |

142+/-10 |

*The real active Af temperature may vary with actual composition, thermo-mechanical history of the product.

We manufactures different medical grades (binary NiTi code D, C, S, E and ternary NiTiV code J) of Nitinol wire products

available in either as straightened super-elastic (SE) wire or the cold worked (CW) condition wire ready for heat treatment.

Heat Treatment Status:

Medical grade Nitinol wire may be purchased in the super-elastic condition (SE) or the cold worked (CW), and after the correct

supper-elastica heater treatment will accommodate strain up to 8% without permanent kinking at body temprature.

Typical transformation temperature

The transformation temperatures and mechanical properties for typical grades of Nitinol are presented in the table below:

|

Nitinol code |

Ni content

|

As straightened super-elastic (SE) |

Cold worked (CW) |

Typical mdeical applications |

|||||

|

sb

|

Δ

|

sload MPa |

sunload

|

Active Af

|

Ingot As

|

sb

|

|||

|

Nitinol-D regular |

55.96 |

> 1240 |

> 10 |

> 482 |

>138 |

+10 ~ +18 |

-30 ~ -10 |

> 1378 |

Guide wires, stents, shapeset parts, stone retrieval baskets, orthodontic files, etc |

|

Nitinol-D High fatiqute |

55.96 |

> 1240 |

> 10 |

> 448 |

>103 |

+14 ~ +22 |

-10 ~ +10 |

> 1378 |

For device require high cycling performance at 37°C |

|

Nitinol-S regular |

55.76 |

> 1000 |

> 10 |

> 400 |

Depand on Af |

+15 ~ +28 |

-10 ~ +10 |

> 1150 |

For device with high fatigue file such as implants, stents & Shapeset parts |

|

NiTiCr |

55.8Ni-0.2~0.3Cr |

> 1447 |

> 10 |

> 551 |

> 241 |

0 ~ +18 |

- 45 ~ - 15 |

> 1722 |

Non-medical applications for higher upper plateau stress at ambient temperatures, such as antenna, eyeglass frame etc. |

|

Remark |

|

All Mechanical Testing Conducted at 22°C +/- 2°C; Permanent Set < 0.5% after strained to 8%; Elongation at Break > 10% |

Elongation at break > 4% |

|

|||||

Nitinol wires Applications:

There are four commonly used types of applications for nitinol.

- Free Recovery: nitinol is deformed at a low temperature, and heated to recover its original shape.

- Constrained Recovery: The same, except that recovery is rigidly prevented, and thus a stress is generated.

- Work Production: Here the alloy is allowed to recover, but to do so it must act against a force (thus doing work).

- Superelasticity: As discussed above, here the nitinol acts as a super spring.

Other applications

- Nitinol is also popular in extremely resilient glasses frames. It is also used in some mechanical watch springs.

- It can be used as a temperature control system; as it changes shape, it can activate a switch or a variable resistor to control the temperature.

- It is used in cell-phone technology as a retractable antenna, or microphone boom, due to its highly flexible and mechanical memory nature.

- It is used in some novelty products, such as self-bending spoons which can be used by amateur and stage magicians to demonstrate " psychic" powers or as a practical joke, as the spoon will bend itself when used to stir tea, coffe, or any other warm liquid.

- It can also be used as wires which are used to locate and mark breast tumours so that following surgery can be more exact.

- Due to the fact it can change shapes it is also used as a golf club insert.

- Nickel titanium can be used to make the underwires for underwire bras.

Send your inquiry details in the below for free sample , click " send " Now!