- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FUOOTECH

-

Voltage:

-

380V, 50Hz, 3Phase, Customer's Requirement

-

Power:

-

18KW to 180KW

-

Dimension(L*W*H):

-

Refer to actual data

-

Weight:

-

850 kg

-

Color:

-

Blue, Gray, White, Yellow

-

After-sales Service:

-

Provided

-

Applicable raw material:

-

Carbon Steel or SS

-

Application:

-

Transformer oil, Insulating oil, Cable oil, Switchgear oil, etc.

-

Function:

-

Oil Filtration, Dehydration, Degassing, Oil Filling, etc.

-

Structure:

-

Three Stage Filters (customizable)

-

Oil pump:

-

Gear type or Screw type

-

Heating method:

-

Indirect Electrical Heating

-

Type:

-

Countinous Vacuum Filtration

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Flow:

-

1800 LPH to 30000 LPH

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

FUOOTECH

-

Voltage:

-

380V, 50Hz, 3Phase, Customer's Requirement

-

Power:

-

18KW to 180KW

-

Dimension(L*W*H):

-

Refer to actual data

-

Weight:

-

850 kg

-

Color:

-

Blue, Gray, White, Yellow

-

After-sales Service:

-

Provided

-

Applicable raw material:

-

Carbon Steel or SS

-

Application:

-

Transformer oil, Insulating oil, Cable oil, Switchgear oil, etc.

-

Function:

-

Oil Filtration, Dehydration, Degassing, Oil Filling, etc.

-

Structure:

-

Three Stage Filters (customizable)

-

Oil pump:

-

Gear type or Screw type

-

Heating method:

-

Indirect Electrical Heating

-

Type:

-

Countinous Vacuum Filtration

FUOOTECH ZYD-T Three Phase Mobile Vacuum Transformer Oil Purifier and Oil Filtration Machine

The main difference between ZYD-T series and other transformer oil filtration plants, it has the special T-shape Horizontal Vacuum Chamber which separates the evaporation tank and the oil tank, improving evaporation efficiency, prolong the machine lifetime.

ZYD-T Series Transformer oil filtration machine can remove trace water, free water, soluble water, dissolved gas, impurities and tiny particles as well as acetylene, hydrogen, methane and other harmful ingredients effectively and rapidly from used or new transformer oil, so as to improve the flash point, acidity, interfacial tension and dielectric strength value of insulating oil.

It suits for purifying all kinds of insulation oils, especially suits for purifying transformer oil from 110KV and above UHV power transmission and distribution projects; also suits for purifying of capacitor oil, mutual inductor oil, switch oil, cable oil.

Routine Maintenance Procedures

|

Filter element inspection, cleaning and replacement

|

After the filter element has been working for a period of time, when the pressure difference through the filter element increases to the design limit due to the clogging of dirt, the filter element must be maintained, including cleaning or replacement. The material and structure of the filter element determine whether it can be cleaned and how to clean it.

|

|

|

Note:

Among the filter elements used in ZYD-T, the coarse filter element FL01 can be cleaned. Fine filter elements FL02, FL03 and vacuum pump oil filter elements cannot be cleaned and must be replaced.

|

|

|

Details Images

Main Functions

1). Removing Moisture/ dehydration : the final treated oil can achieve less than 3 ~ 5ppm;

2). Degassing: the final treated oil can achieve less than ≤0.05%;

3). Removing Particles: the final treated oil can achieve 1 micron;

4). Vacuum oil filling/transferring;

5). Vacuum drying equipment for transformers;

6). Vacuum purification online work, unattended operation (at certain working condition).

2). Degassing: the final treated oil can achieve less than ≤0.05%;

3). Removing Particles: the final treated oil can achieve 1 micron;

4). Vacuum oil filling/transferring;

5). Vacuum drying equipment for transformers;

6). Vacuum purification online work, unattended operation (at certain working condition).

Oil Before and After Treatment

Product Paramenters

|

Parameters

|

|

Model

Unit |

ZYD-T-30

|

ZYD-T-50

|

ZYD-T-100

|

ZYD-T-150

|

ZYD-T-200

|

ZYD-T-250

|

ZYD-T-300

|

|||||||||

|

Flow Rate

|

|

Liter/hour

|

1,800

|

3,000

|

6,000

|

10,000

|

12,000

|

15,000

|

18,000

|

|||||||||

|

Recommended Max. oil volume in one storage tank

|

|

Tons

|

6

|

12

|

24

|

40

|

60

|

90

|

110

|

|||||||||

|

Relative Working

Vacuum Degree |

|

MPa

|

-0.08 ~ -0.099 MPa

|

|

|

|

|

|

|

|||||||||

|

Absolute Operating

Vacuum Level |

|

Pa

|

≤ 8 Pa

|

|

|

|

|

|

|

|||||||||

|

Working Discharge Pressure

|

|

MPa

|

≤ 0.5

|

|

|

|

|

|

|

|||||||||

|

Temperature Control

|

|

℃

|

0 ~ 100

|

|

|

|

|

|

|

|||||||||

|

Operation Oil Temperature

in Treatment |

|

℃

|

30 ~ 80 (65℃ is best)

|

|

|

|

|

|

|

|||||||||

|

Power Supply

|

|

|

AC 3~, 380 V, 50Hz, 4 Wire (or as per your requirements)

|

|

|

|

|

|

|

|||||||||

|

Operation Mode

|

|

|

Continuous Operation

|

|

|

|

|

|

|

|||||||||

|

Working hours

without Trouble |

|

Hour

|

4000

|

|

|

|

|

|

|

|||||||||

|

Continuous Working Hours

|

|

Hour

|

150

|

|

|

|

|

|

|

|||||||||

|

Ambient Temperature

|

|

|

-25 ~ 55℃

|

|

|

|

|

|

|

|||||||||

|

Working Noise

|

|

dB(A)

|

65 ~ 85

|

|

|

|

|

|

|

|||||||||

|

Cooling Method

|

|

|

Air Cooling

|

|

|

|

|

|

|

|||||||||

|

Heating Power

(adjusted available) |

|

KW

|

30

|

72

|

90

|

120

|

135

|

150

|

180

|

|||||||||

|

Total Power

|

|

KW

|

36

|

78

|

105

|

136

|

150

|

170

|

206

|

|||||||||

|

Inlet/Outlet

|

|

mm

|

φ25

|

Φ32

|

φ50

|

φ50

|

φ50

|

φ60

|

φ60

|

|||||||||

|

Weight

|

|

Kg

|

500

|

900

|

1200

|

1400

|

1650

|

1800

|

1950

|

|||||||||

|

Dimension

|

Length

|

mm

|

1380

|

1710

|

1800

|

2010

|

2060

|

2100

|

2200

|

|||||||||

|

|

Width

|

mm

|

1020

|

1510

|

1560

|

2030

|

2100

|

2150

|

2250

|

|||||||||

|

|

Height

|

mm

|

1760

|

1860

|

2080

|

2080

|

2200

|

2450

|

2550

|

|||||||||

|

After Treatment

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Dielectric Strength

|

|

kV

|

≥ 70 ~ 80

|

|

|

|

|

|

|

|||||||||

|

Water Content

|

|

PPM

|

≤ 3 ~ 5

|

|

|

|

|

|

|

|||||||||

|

Gas Content

|

|

%

|

≤ 0.1

|

|

|

|

|

|

|

|||||||||

|

Particle Size

|

|

μm

|

≤ 3

|

|

|

|

|

|

|

|||||||||

|

Cleanliness

|

|

|

≤NAS 1638 Grade 5

|

|

|

|

|

|

|

|||||||||

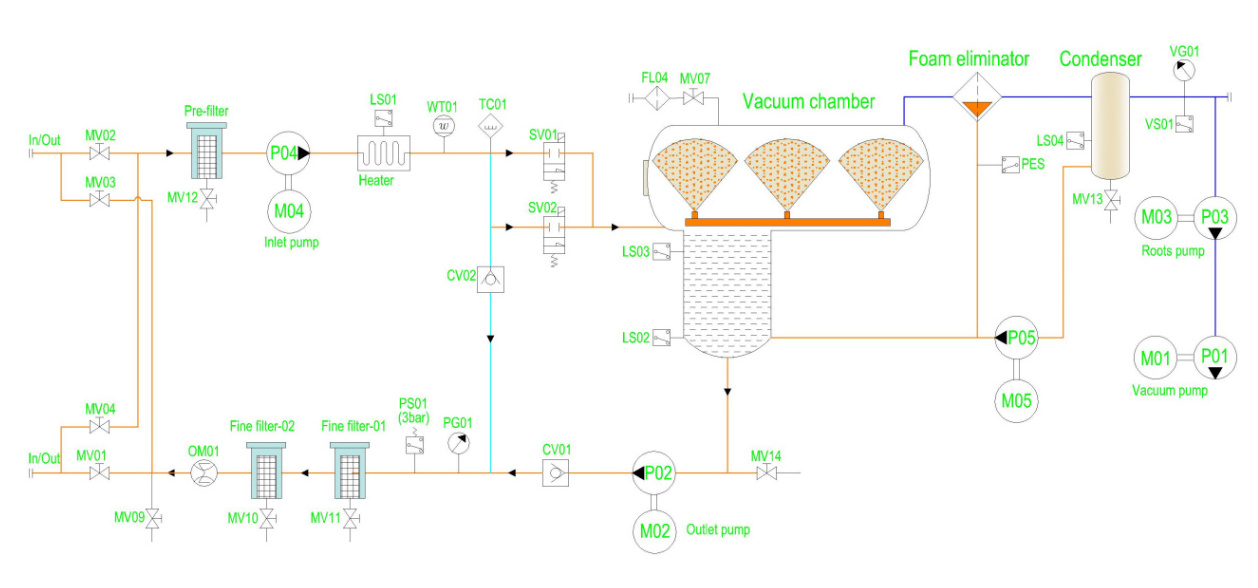

Working Principle

When this machine start working and vacuum degree is upto the set value, the used oil will be sucked into the pre-filter under the pressure difference, the pre-filter will remove the big size impurities/ particles, then the oil which just contains the tiny particles is heated by the heaters. Then the heated oil enter into the vacuum separator chamber, through the function of vacuum pressure and degassing system, the moisture content in the oil, which is vapoured & Separated from the oil quickly, is either discharged under the process of the vacuum system or refrigerated to liquid water into water receiver, meanwhile degasification work is completed, then oil is pumped into fine filter 2 to remove more particles, and fine filter 1 removes the tiny impurities completely. Finally, clean oil goes out through the oil outlet.

Product Advantages

Product Details

On-Site Project Photos

FUOOTECH Group is established in 2002, located at Chongqing city, China. It is engaged in designing, manufacturing and exporting various vacuum oil purifier machine, oil filtration system, oil regeneration machine, oil flushing system, oil testing machine, transformer vacuum pumping system, dry air generator, transformer & high voltage Tester, etc. All our products satisfy the international quality standard, passed CE and ISO 9001 certificate, verified by SGS.

FUOOTECH’s products are extensively used in the more than 45 industry lines including but not limited to the fields of electrial power, power station, power transmission, power distribution, power generation, petrochemical, petroleum, paper & pulp, compressor, mechanical manufacture, steel mills, electrical utilities, engineering contractors, metallurgy,railway, aviation, minging, etc.

Q1. ARE YOU A MANUFACTURERTRADING COMPANY OR A THIRD PARTY?WHEN AND WHERE DID YOUR FACTORY ESTABLISHED?

FUOOTECH: We are a manufacturer established since 2002, located at Chongqingcity, China.

Q2.WILL THE PRODUCTS BE TESTED BEFORE SHIPPING?

FUOOTECH: Yes, of course. QC personal will have a strict testing procedure to allthe products before shipping.

Q3.WHATS YOUR WARRANTY PERIOD?

FUOOTECH: We offer 24 months of warranty for all our products from the date ofshipment. Even if the warranty period is expired, we still provide lifelong maintenance.technical service and spare parts supply.

Q4: WHAT IS THE DELIVERY TIME OF YOUR MACHINE?

FUOOTECH: In general, the delivery time of our standard machine is about 15 days.

customized machine will be delivered as the negotiation with our clients.

Q5.WHAT IS THE USAGE OF A VACUUM OIL PURIFIER?

FUOOTECH: Dehydration, degassing, impurity removal of old oil, and extend oillife.

Q6.WHATIS CONSUMABLE?

FUOOTECH: There is no consumable except filters

Q7.WHO SHOULDICONTACT TO GET MORE INFORMATION ?

FUOOTECH: ATTN: Mr Tim or Kevin, Email: sales@fuootech.com, WhatsappTel:+86 135 2739 0908

Hot Searches