- Product Details

- {{item.text}}

Quick Details

-

Material:

-

-

-

Weight:

-

-

-

Size:

-

-

-

Power:

-

-

-

Weight (KG):

-

30 kg

-

Product name:

-

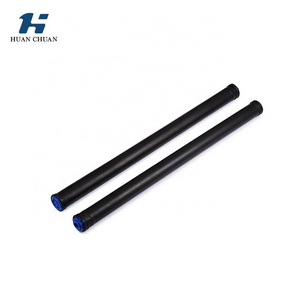

EPDM tube fine bubble air diffuser for aquarium fish tank

-

Type:

-

YLG-65-1000

-

Outer Diameter:

-

67mm

-

Aeration capacity:

-

4.0~6.0m3/h

-

Service area:

-

0.4~2m2/piece

-

Connector size:

-

G3/4' screwed connection

-

Membrane material:

-

EPDM or Silicone

-

Application:

-

Waste Water Treatment

-

Other name:

-

tublar aerator

-

Color:

-

Black

Quick Details

-

Core Components:

-

epdm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YULONG

-

Material:

-

-

-

Weight:

-

-

-

Size:

-

-

-

Power:

-

-

-

Weight (KG):

-

30 kg

-

Product name:

-

EPDM tube fine bubble air diffuser for aquarium fish tank

-

Type:

-

YLG-65-1000

-

Outer Diameter:

-

67mm

-

Aeration capacity:

-

4.0~6.0m3/h

-

Service area:

-

0.4~2m2/piece

-

Connector size:

-

G3/4' screwed connection

-

Membrane material:

-

EPDM or Silicone

-

Application:

-

Waste Water Treatment

-

Other name:

-

tublar aerator

-

Color:

-

Black

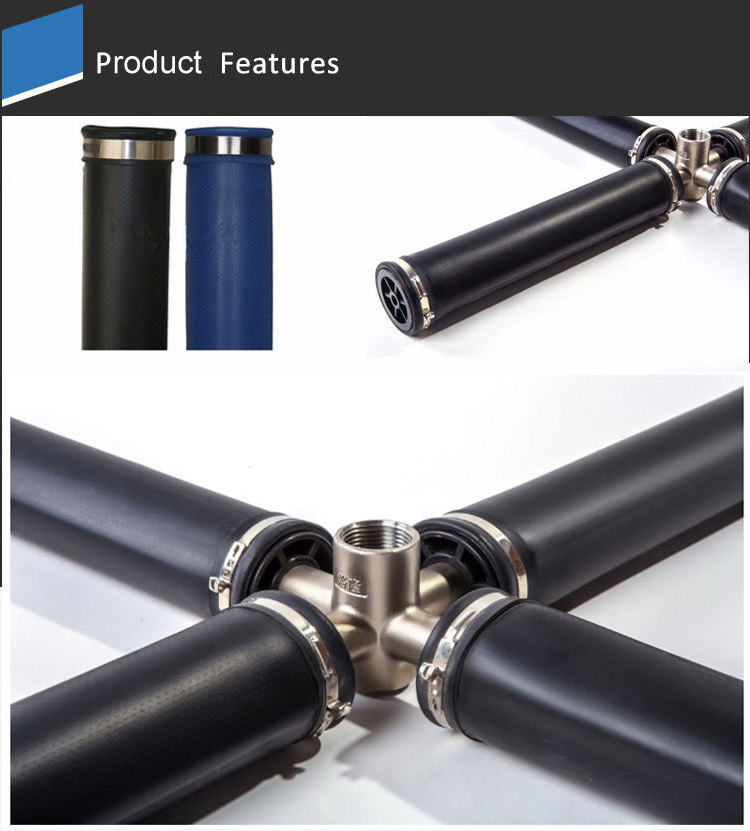

YLG-65-1000 epdm membrane aerator air tube diffuser with High dissolved oxygen rate

| Serive Area |

10~20(m2/set)

|

||

| Air pore Length |

0.8~2mm

|

||

| Membrane Diameter |

65~69mm

|

||

| Dissolved Oxygen Effect |

>6(in clean water)

|

||

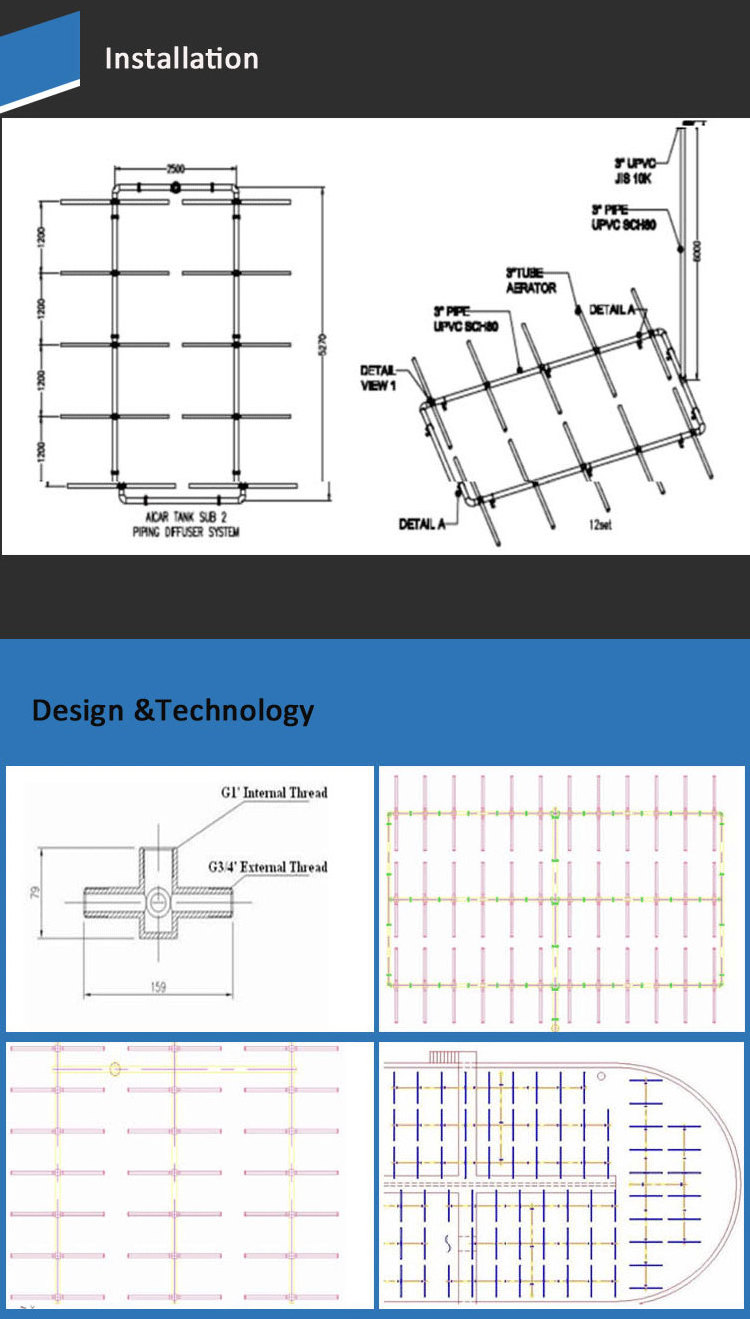

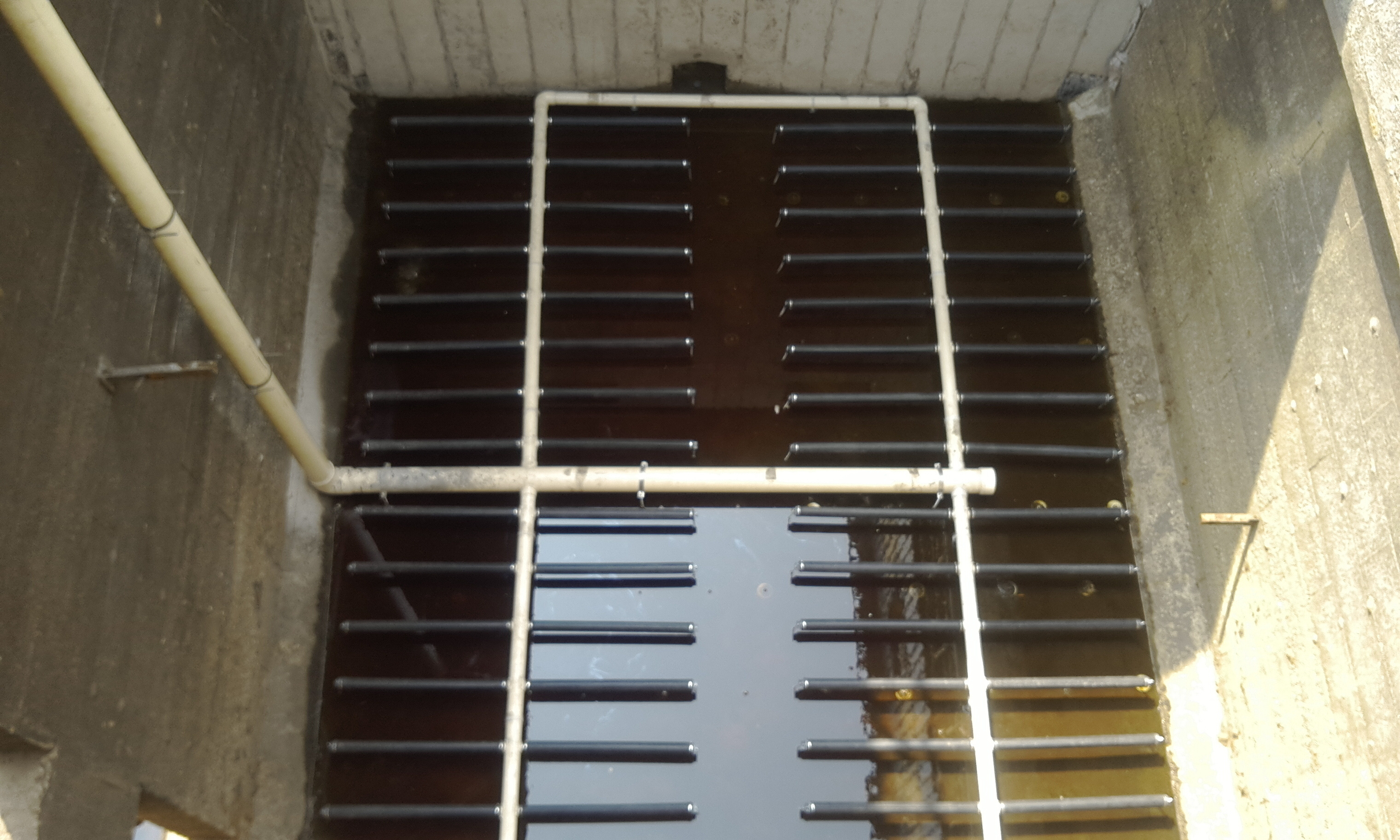

The lifting-type tube air diffuser is developed by our company over year’s efforts. It is a new type of oxygenation aerator and the core equipment of A/O process (activated sludge biochemistry technology). It can be applied to every position of the sewage pool. It is featured by easy and convenient installation and maintenance, even oxygenation and low energy consumption.

Flexible, easy and convenient installation. It can be installed during normal operation, not necessary to drain water. Simple maintenance.

1, The rubber membrane pipe is made from imported ethylene-propylene diene copolymer (EPDM) or silicon rubber, which makes the membrane anti-aging, corrosion-resisting and long service life, as long as 5 to 8 years.

2, The aerating hole is evenly formed, leading to good expandability and instant closing. During aerating work, the fine bubbles (1 – 3 mm) can be generated and the oxygenation utilization can be as high 35 – 42%.

3, The gas vent is used to distribute the gas in a quick and even way. The aerating membrane stresses evenly, which can increase the service life of the rubber diaphragm pipe and the uniformity of released bubbles and improve the aerating effect.