-Layout:Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an

equipment footprint according to your requirement.

-Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

-3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-80KW(customizable)

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

KG

-

Model Number:

-

HG-30000L

-

Useful capacity:

-

30m³

-

Gross capacity:

-

36m³

-

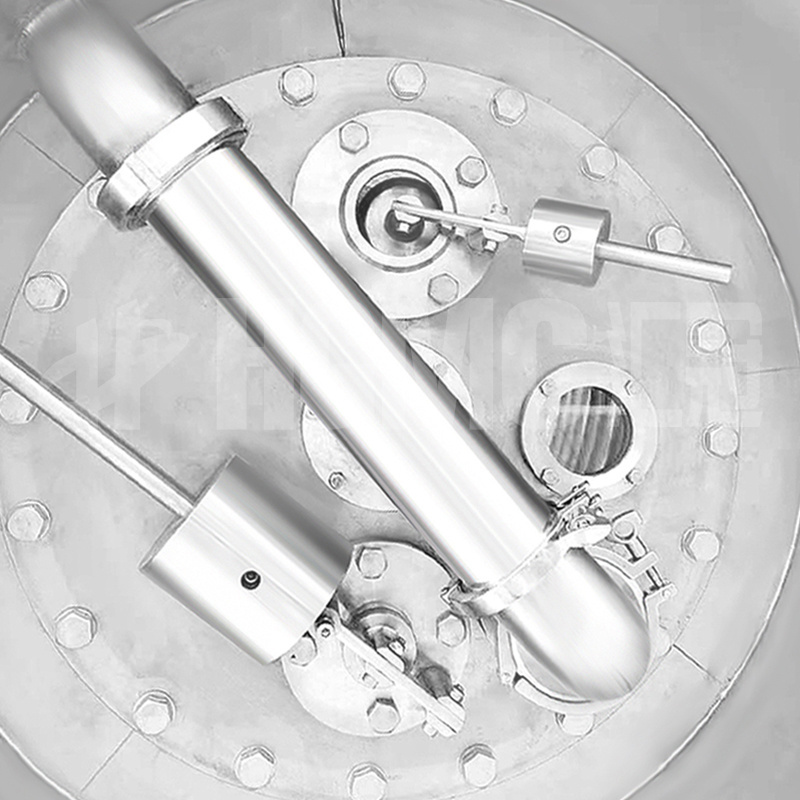

diameter:

-

inner diameter:2800mm; external diameter:3100mm

-

Thickness:

-

Head: 5mm, tank:4mm

-

Lower cone:

-

5mm

-

Material:

-

SUS304

-

Operating pressure:

-

Operating pressure

-

Heat exchange area:

-

30㎡

-

Cleaning method:

-

CIP cleaning in place

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Voltage:

-

3phase/380(customizable)

-

Power:

-

0-80KW(customizable)

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

KG

-

Model Number:

-

HG-30000L

-

Useful capacity:

-

30m³

-

Gross capacity:

-

36m³

-

diameter:

-

inner diameter:2800mm; external diameter:3100mm

-

Thickness:

-

Head: 5mm, tank:4mm

-

Lower cone:

-

5mm

-

Material:

-

SUS304

-

Operating pressure:

-

Operating pressure

-

Heat exchange area:

-

30㎡

-

Cleaning method:

-

CIP cleaning in place

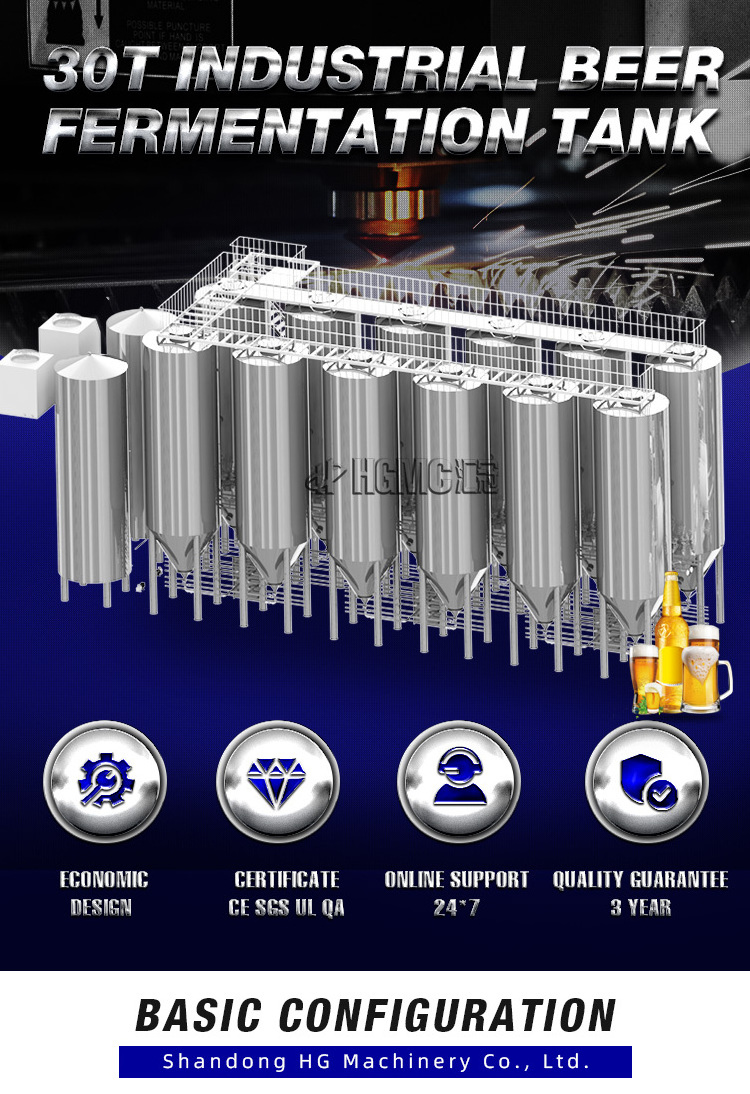

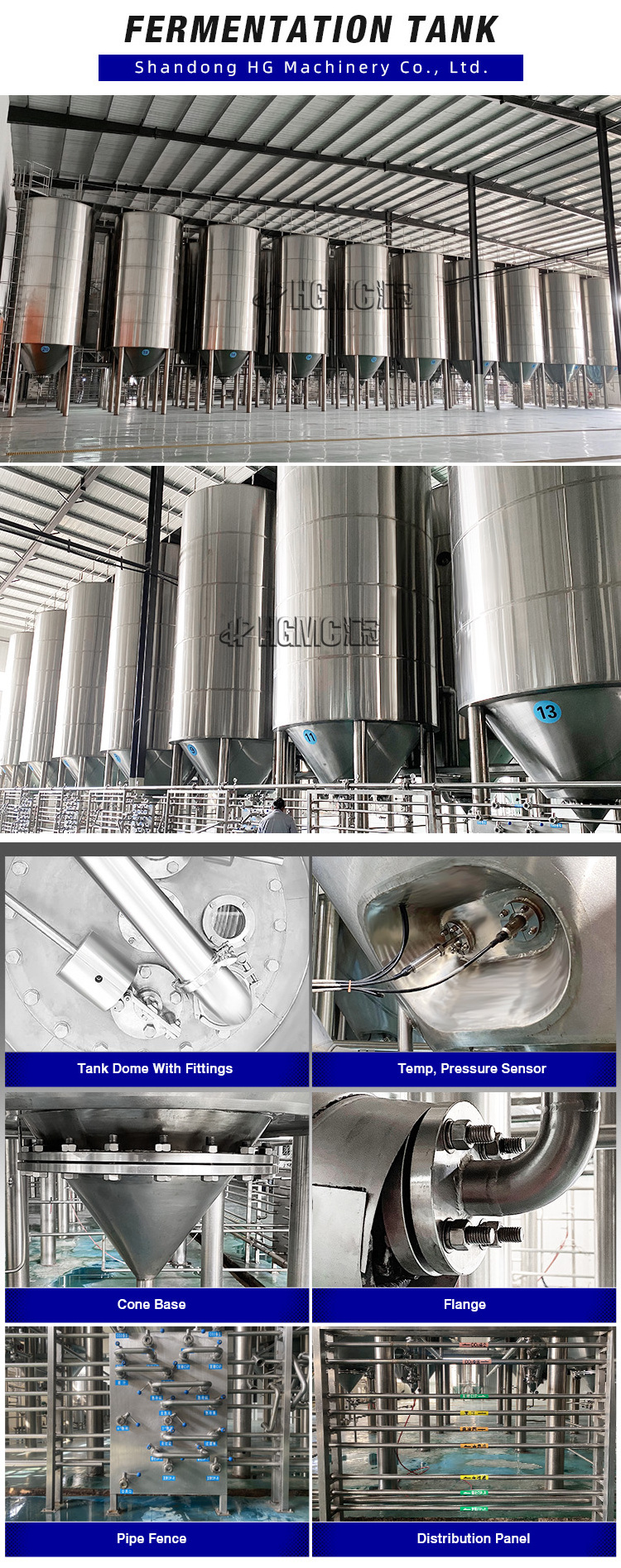

30000L 20T 30T 50T Industrial Stainless Steel Beer wine fermentation Tank /beer fermenting equipment with cooling jacket

|

1

|

Model

|

HG-30000L

|

|

2

|

Effective volume/total volume

|

30m³/36m³

|

|

3

|

Diameter

|

Inner:2800,outer:3100,

|

|

4

|

Thickness

|

Head: 5mm, tank:4mm

|

|

5

|

Lower cone

|

5mm

|

|

6

|

Material

|

SUS304

|

|

7

|

Operating pressure

|

0.2MPa

|

|

8

|

Heat exchange area

|

30㎡

|

|

9

|

Height

|

9250mm

|

|

10

|

Cleaning method

|

CIP cleaning in place

|

|

11

|

Temperature measurement method

|

PT100, temperature transmission

|

|

12

|

Insulation

|

Polyurethane-thickness: 100mm

|

|

13

|

Test pressure

|

0~0.6MPa

|

|

14

|

Measurement accuracy

|

0.01 MPa

|

|

15

|

Protective layer

|

Use 2mm stainless steel wire drawing plate as the outer protective layer

|

Fermenter advantage :

1. 304 stainless steel plate as a whole, and our stainless steel plate manufacturer is the best in China .

1. 304 stainless steel plate as a whole, and our stainless steel plate manufacturer is the best in China .

2. The cooling efficiency of Maitreya plate jacket is greatly improved.

3. Two stage cooling mode .

4. The insulation layer material is high-gradepolyurethane with a thickness of 80mm .

5. Polishing accuracy up to Ra0.4μ m .

6. Strict tank pressure test .

7. Energy conservation and pollution emissions.

1.How to achieve temperature control?

2.Which countries your products are exported to?

4.How long is your delivery time?

5.Do you provide after-sales service?

The PLC or digital dispalyer could control the temperature by connecting with the PT 100 sensor.The brewing tanks with rock wool to keep warm,the fermenters and bright beer tank with PU as cooling jacket to keep cool.

2.Which countries your products are exported to?

Our stainless steel microbrewery equipment are sold all over the world and with related certifications.

3.How to use your machine?

We have paper instructions in English, and we will teach till you do it well.

4.How long is your delivery time?

Usually it takes about 50 working days to manufacture a brewery.Depending on the size of the brewery,the amount of custom designed equipment,our general workload and the way of shipping this period can be shorter or longer.

5.Do you provide after-sales service?

Yes,we could provide after-sales service.We have many professional engineers, they can go to your place and teach your person installation and brewing

6).

6-year warranty, only for tanks, excluding electrical appliances, wearing parts such as cushions, seals, etc. (mixing seals, pump seals, butterfly valves and other valve seals), pumps.

7).

The price does not include electrical appliances, etc.

1.Pre-service:

2.After service :

We guarantee the quality of the electrical elements within 1year and tanks body within 1 years. If the electrical elements go wrong without artificial factors within one year, we will freely provide them or maintain them for you.

After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever

you have technical question in using it, we will freely do our best to support. We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever

you have technical question in using it, we will freely do our best to support. We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

Hot Searches