- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

K9, K10, K11, K12,K9, K8, C25, C30, C40, etc.

-

Length:

-

6m, cut to 5.7m

-

Application:

-

Water supply project, drainage, irrigation,etc

-

Hardness:

-

≤230HB

-

Pipe Wall Thickness:

-

K9, K8, Class C25 C30 C40

-

Pull Strength:

-

≥420MPa

-

Yield (≥ MPa):

-

300MPa

-

Product name:

-

EN545 /ISO2531/EN598 Ductile Cast Iron Pipe

-

Keyword:

-

Ductile Iron Pipe Cap

-

Color:

-

Black

-

Usage:

-

Sewer Water Piping

-

Certification:

-

ISO2531:1998

-

Internal coating:

-

Mortar Cement Lining

-

Test:

-

100% Water Pressure Test

-

External Coating:

-

Zinc + Bitumen Painting

-

MOQ:

-

5 Ton

-

Payment:

-

T/T ,L/C

Quick Details

-

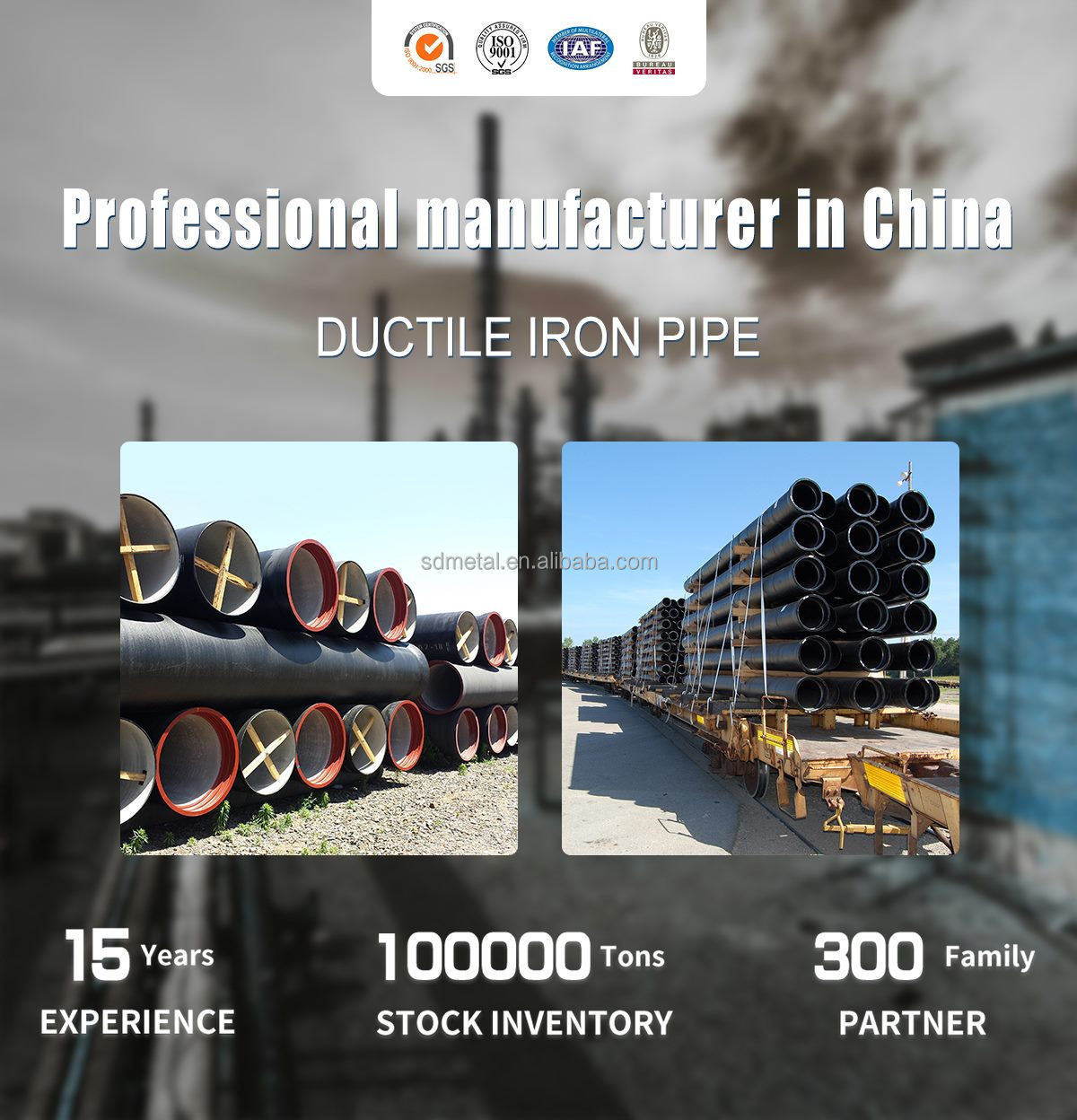

Standard:

-

ISO2531, EN545, EN598

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

guoming

-

Model Number:

-

K9, K10, K11, K12,K9, K8, C25, C30, C40, etc.

-

Length:

-

6m, cut to 5.7m

-

Application:

-

Water supply project, drainage, irrigation,etc

-

Hardness:

-

≤230HB

-

Pipe Wall Thickness:

-

K9, K8, Class C25 C30 C40

-

Pull Strength:

-

≥420MPa

-

Yield (≥ MPa):

-

300MPa

-

Product name:

-

EN545 /ISO2531/EN598 Ductile Cast Iron Pipe

-

Keyword:

-

Ductile Iron Pipe Cap

-

Color:

-

Black

-

Usage:

-

Sewer Water Piping

-

Certification:

-

ISO2531:1998

-

Internal coating:

-

Mortar Cement Lining

-

Test:

-

100% Water Pressure Test

-

External Coating:

-

Zinc + Bitumen Painting

-

MOQ:

-

5 Ton

-

Payment:

-

T/T ,L/C

Product Details

Hot rolled steel is steel that has been roll-pressed at very high temperatures—over 1,700, which is above the re-crystallization temperature for most steels. This makes the steel easier to form, and resulting in products that are easier to work with. To process hot rolled steel, manufacturers first start with a large, rectangular length of metal, called a billet. The billet is heated and then sent for pre-processing, where it is flattened into a large roll. From there, it is kept at a high temperature and run through a series of rollers to achieve its finished dimensions. Steel shrinks slightly as it cools. Since hot rolled steel is cooled after processing, there is less control over its final shape, making it less suitable for precision applications. Hot rolled steel is often used in applications where minutely specific dimensions aren't crucial.

|

Product Name

|

Ductile cast iron pipe

|

|

Diameter

|

DN80mm-DN1600mm

|

|

Length

|

6000mm

|

|

Yield (≥Mpa)

|

270

|

|

Hardness

|

230HB

|

|

Pull Strength

|

420Mpa

|

|

Grade

|

K7, K8, K9, K10

|

|

Material

|

Ductile iron

|

|

Joint Structure

|

Push-on joint/mechanic joint

|

|

Certification

|

ISO2531/EN545/EN598/BV/WARS/SGS

|

|

Internal coating

|

Mortar cement lining/high alumina cement mortar lining

|

|

External coating

|

Zinc + bitumen painting+ epoxy painting

|

|

Color

|

Black bitumen/red epoxy

|

|

Quality Control

|

100% inspection + professional Lab test

|

|

Application

|

Sewage water/dringking water

|

|

Package

|

Packed by steel strips or as customized

|

|

Processing Service

|

Lining and spraying

|

Specifications:

1) The standard of pipe: ISO 2531, EN545 , EN598.

2) Pipe class: K9, C40, C30, C25, etc.

3) Pipe joint: push-on joint(Tyton joint), K type joint, self-restrained joint

4) Effective length: in general, the pipe length is 6m for bulk shipment and 5.7m for container shipment.

5) Internal lining: cement mortar lining as per ISO4179

6) Zinc coating: at least 130g/m2 as per ISO 8179

7) Bitumen painting: at least 70um as per ISO 8179

8) Gaskets are NBR rubber, natural rubber, SBR rubber or EPDM rubber ring as per ISO4633

9) DN 80 - 2,600 mm

10) High strength, lighter than gray iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life time

11) Checked by automatic inspection equipment

12) Chemical composition: (%)

a) C: 3.5 - 4.0

b) Si: 1.9 - 2.6

c) Mn:0.15 - 0.45

c) P: <0.06

d) S: <0.02

13) Mechanical properties

a) Tensile strength: ≥420MPa

b) Yield strength: ≥300Mpa

c) Hardness: ≤230HB

d) Elongation%: DN80 - 1000 ≥10 DN1200 - 2200 ≥7

14) Process and testing:

a) Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)

b) Casting (Visual check and weight check)

c) Heat treatment (Micro structure)

d) Hydrostatic test (Pressure test)

e) Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)

f) Zinc spraying (Thickness testing)

g) Lining and coating (100% visual check, thickness testing randomly)

i) Marking and packing (100% visual check)

15) The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc.

|

Based on joints

|

STD joint

|

|

|

T-type push-on joint

|

|

|

Binding joint

|

|

Based on internal and external coatings

|

Common coating

|

|

|

The internal coating of surface cement mortar

|

|

|

The internal coating of aluminate cement mortar

|

|

|

Zinc-aluminum coating

|

|

|

The internal coating of epoxy ceramic

|

|

|

Epoxy resin seal coating

|

|

|

Polyurethane coating

|

Hot Searches