- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

Structure: lifetime

-

Standard:

-

VIA/JWL . TUV . SAE-J2530

-

Size:

-

20~22

-

H-PCD:

-

5x108/5x120

-

CB:

-

72.6

-

MOQ:

-

4 Pieces

-

Delivery time:

-

25 days after 50% deposit

-

PRICE:

-

Negotiable

Quick Details

-

Width:

-

9.0~12

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSHA

-

Warranty:

-

Structure: lifetime

-

Standard:

-

VIA/JWL . TUV . SAE-J2530

-

Size:

-

20~22

-

H-PCD:

-

5x108/5x120

-

CB:

-

72.6

-

MOQ:

-

4 Pieces

-

Delivery time:

-

25 days after 50% deposit

-

PRICE:

-

Negotiable

Images

|

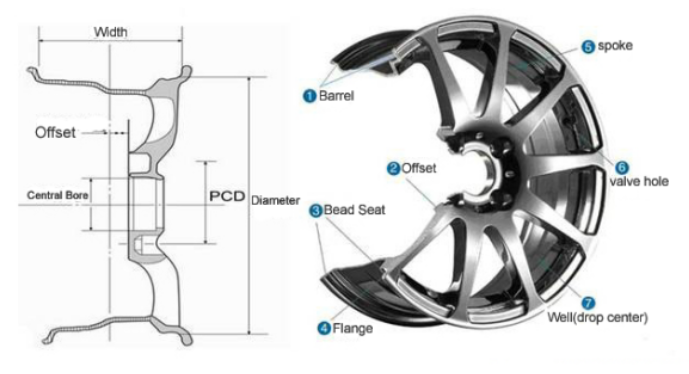

Size

|

19'' 20''

|

H/PCD

|

5*112

|

|

ET

|

20

|

CB

|

57.1-74.1

|

|

Material

|

A6061

|

Weight

|

11kg/12kg

|

|

Colour

|

Stain silver

|

Finish

|

Machined Face

|

Products Description

·Material: A6061 T6

·Load Rating: we make based on VIA/JWL standard

·Function: For luxury car

·Load Rating: we make based on VIA/JWL standard

·Function: For luxury car

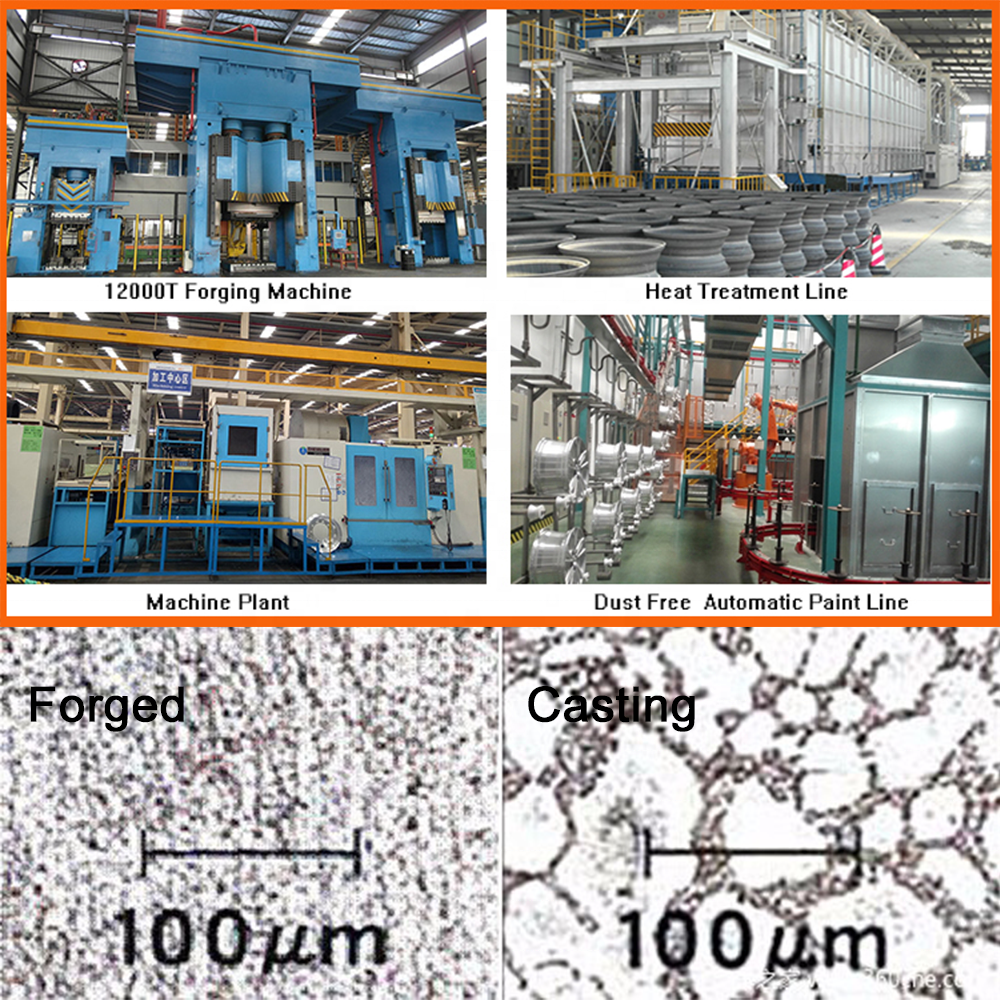

Light

light weight, fuel saving compared to casting rims, and only slight deformation after impact, even if the puncture can share the weight of the car, it will not cause rollover.

Safe

high rigidity, The forged wheel is much safer than the casting wheel. Since the casting wheel is cooled by the molten liquid

metal filling cavity, it is easy to produce air holes in the manufacturing process; and the forged wheel is mainly extruded at a

high temperature to soften the aluminum block. The method of molding. Therefore, the molecular density and the molecular spacing

are smaller than those of the casting wheels, so the wheel rigidity is greatly improved. Moreover, because the forging process

makes the molecular structure very tight, it can withstand higher pressures, so the forged wheels are lighter and use less

material than the cast wheels at the same strength and strength.

metal filling cavity, it is easy to produce air holes in the manufacturing process; and the forged wheel is mainly extruded at a

high temperature to soften the aluminum block. The method of molding. Therefore, the molecular density and the molecular spacing

are smaller than those of the casting wheels, so the wheel rigidity is greatly improved. Moreover, because the forging process

makes the molecular structure very tight, it can withstand higher pressures, so the forged wheels are lighter and use less

material than the cast wheels at the same strength and strength.

Product Details

Hot Searches