Stamping production is mainly for sheet metal. Through dies, blanking, punching, forming, drawing, trimming, fine blanking, shaping, riveting and extrusion parts can be made, which are widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, and even missile aircraft... There are a lot of accessories that can be produced by punching machines through molds.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V/400V

-

Dimension(L*W*H):

-

1600*1100*2250MM

-

Motor Power (kW):

-

4

-

Model Number:

-

J23-40

-

Weight (T):

-

2.5

-

Marketing Type:

-

New Product

-

Product name:

-

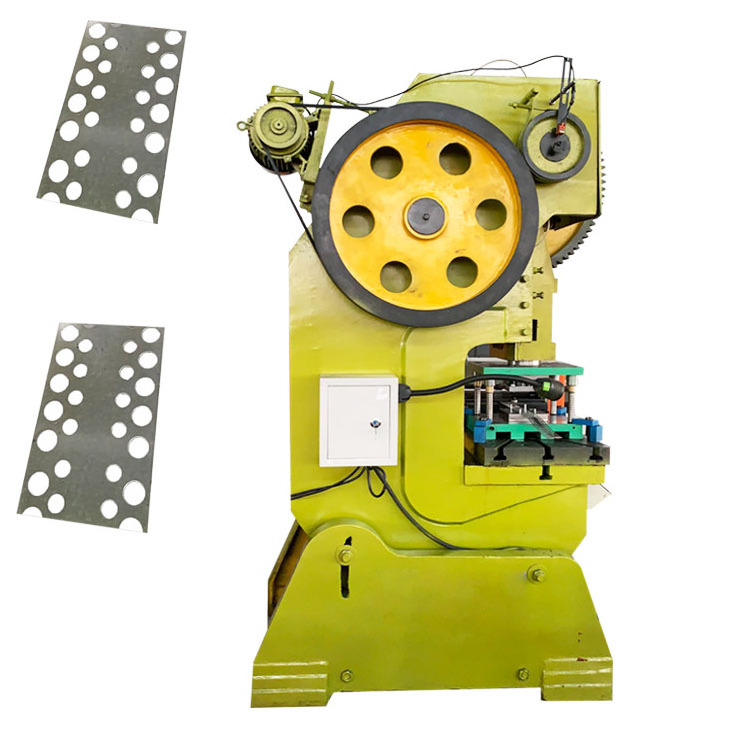

Power Press Machine

-

Application:

-

Metal Sheet Stamping

-

Usage:

-

Pressing Metal Products

-

Type:

-

Standard Punch

-

Control:

-

Hand Control

-

Material:

-

Steel Material

-

Advantage:

-

High Efficiceny

-

Color:

-

Green

-

Finished Products:

-

Aluminum Foil Bowl

-

Machine Function:

-

Punching Cutting Shape Forming

Quick Details

-

Slide Stroke (mm):

-

80

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hoson

-

Voltage:

-

220V/380V/415V/440V/400V

-

Dimension(L*W*H):

-

1600*1100*2250MM

-

Motor Power (kW):

-

4

-

Model Number:

-

J23-40

-

Weight (T):

-

2.5

-

Marketing Type:

-

New Product

-

Product name:

-

Power Press Machine

-

Application:

-

Metal Sheet Stamping

-

Usage:

-

Pressing Metal Products

-

Type:

-

Standard Punch

-

Control:

-

Hand Control

-

Material:

-

Steel Material

-

Advantage:

-

High Efficiceny

-

Color:

-

Green

-

Finished Products:

-

Aluminum Foil Bowl

-

Machine Function:

-

Punching Cutting Shape Forming

Product Overview

China Mechanical Hydraulic Power Press Stamping Steel Machine Metal Punching Machine For Punching and Stamping

J23 Series Presses is for cutting, punching,blanking, bending and light stretching work.c- frame provides maximum rigidity and minimum deflection for accurate parts and long tool life.Steel-welded frame, high rigidity and less deformation Compact.Thick plates and large columns provide you with the stable platform you need for your demanding application.

Product Paramenters

|

Model and specification

|

J23-16

|

J23-25

|

J23-40

|

J23-60

|

J23-80

|

|

Nominal pressure (kn)

|

160

|

250

|

400

|

630

|

800

|

|

Slipper stoke (mm)

|

50

|

70

|

80

|

80

|

100

|

|

Slipper stoke times(time/min)

|

110

|

65

|

50

|

50

|

50

|

|

Max closing height (mm)

|

170

|

200

|

220

|

250

|

270

|

|

Height adjustment(mm )

|

30

|

30

|

45

|

5

|

60

|

|

Distance between slipper centre and machine(mm)

|

160

|

200

|

200

|

250

|

260

|

|

Worktable dimension(mm)

|

320*460

|

350*520

|

390*630

|

420*650

|

470*750

|

|

Size of die handle bore (mm)

|

40*60

|

40*60

|

50*70

|

50*70

|

60*80

|

|

Worktable thickness(mm)

|

45

|

50

|

70

|

70

|

80

|

|

Slipper underside bore (mm)

|

120*180

|

170*220

|

210*250

|

240*280

|

260*300

|

|

Motor(kw)

|

1.5

|

3

|

4

|

5.5

|

5.5

|

Products Description

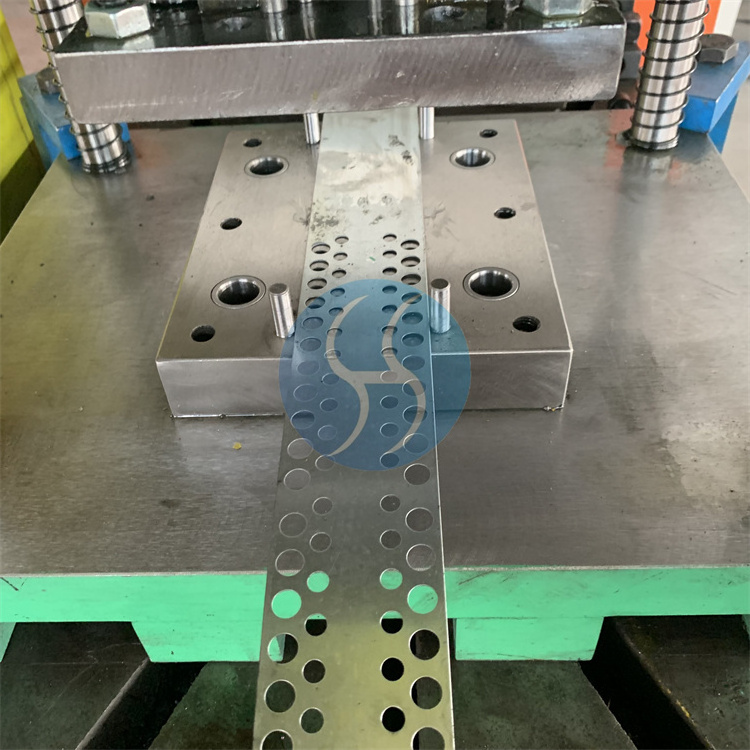

Metal Punchine Hole Eccentric Press Machine .

Punch is a stamping press. In the national production, the stamping process has the advantages of saving materials and energy, high efficiency, low technical requirements for operators and making products that can not be achieved by mechanical processing through various mold applications, compared with traditional mechanical processing, so its use is more and more extensive.

Stamping production is mainly for sheet metal. Through dies, blanking, punching, forming, drawing, trimming, fine blanking, shaping, riveting and extrusion parts can be made, which are widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, and even missile aircraft... There are a lot of accessories that can be produced by punching machines through molds.

Stamping production is mainly for sheet metal. Through dies, blanking, punching, forming, drawing, trimming, fine blanking, shaping, riveting and extrusion parts can be made, which are widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, and even missile aircraft... There are a lot of accessories that can be produced by punching machines through molds.

Feature of C-type Power Press/ Punching Machines:

1. Its structure is simple, operation convenience, function credibility, the usage maintain convenience.

2. J23 series shut type list orders the pressure machine fuselage of airplane straight line form design, well balanced to be subjected to dint, constant form, rigid and strong.

3. Extremely high closing height, pack the mold space big, slippery piece the piece six noodles direction, the accuracy is high,stability good.

4. Outside support type especially the big machine do, exaltation the tool machine install stability, safety, inside place type, oil road, electric circuit, beauty clean and net, have a safety, dependable type more,

5. The hand operation button the switch match pressure machine national security standard.

2. J23 series shut type list orders the pressure machine fuselage of airplane straight line form design, well balanced to be subjected to dint, constant form, rigid and strong.

3. Extremely high closing height, pack the mold space big, slippery piece the piece six noodles direction, the accuracy is high,stability good.

4. Outside support type especially the big machine do, exaltation the tool machine install stability, safety, inside place type, oil road, electric circuit, beauty clean and net, have a safety, dependable type more,

5. The hand operation button the switch match pressure machine national security standard.

Application and Characteristics

of Punching Machine Punching machines are widely used in stamping and forming of electronic,communication, computer, household appliances, furniture, vehicles, (automobiles, motorcycles, bicycles) hardware parts, etc.

1.Stable without deformation

(1) The frame with high rigidity and high precision is welded with steel plate, and the internal stress of the fuselage is eliminated through heat treatment to make the equipment work stably for a long time without deformation.

(2)The load of structural members shall be uniform and the rigidity shall be balanced.

2. Stable and high precision:

The crankshaft,gear, transmission shaft and other parts of the main components of the equipment have high wear resistance after hardening and heat treatment, and long-term performance is stable, ensuring the requirements of high accuracy and stability.

3. Reliable and safe operation performance:

The reason for convenient operation and accurate positioning is that the combination device of clutch/brake, which is different from the traditional brake, has high sensitivity. In addition, the dual-connected electromagnetic control valve and overload protection device commonly used by international high-end equipment ensure the accuracy and safety of high-speed movement and stop of the press slider.

4. Production automation, labor saving and high efficiency.

The press can be equipped with corresponding automatic feeding device, with feeding error detection, pre-cutting and pre-cutting devices, which can fully realize automatic production, with low cost and high efficiency.

5. Slider adjusting mechanism:

The sliding adjustment is divided into manual adjustment and electric adjustment, which is convenient, reliable, safe and fast, and the accuracy can reach 0.1mm.

6. Novel design and environmental protection.

It adopts the advanced technology and design concept of Japan and Taiwan, and has the advantages of low noise, low energy consumption and no pollution.

Hot Searches