- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

kaida

-

Application:

-

plastic Bottle recycling machine

-

Production Capacity (kg/h):

-

500 - 1000

-

Voltage:

-

380V,50HZ,3PH(according to customer)

-

Dimension(L*W*H):

-

Depends on product configuration

-

Power (kW):

-

300

-

Weight (T):

-

2

-

Name:

-

Plastic recycling and cleaning line

-

After Warranty Service:

-

Video technical supportonline

-

Certification:

-

ISO9001

-

After-sales service provided:

-

Video technical supportonline

-

Main Selling Points:

-

Customization support

-

Advantages:

-

Price Advantage

-

Customized:

-

Customization support

-

color:

-

According to customer needs

-

Human Customer Service:

-

24 hours online answer welcome consultation

-

Material:

-

HQ 304 stainless steel

Quick Details

-

Machine Type:

-

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

kaida

-

Application:

-

plastic Bottle recycling machine

-

Production Capacity (kg/h):

-

500 - 1000

-

Voltage:

-

380V,50HZ,3PH(according to customer)

-

Dimension(L*W*H):

-

Depends on product configuration

-

Power (kW):

-

300

-

Weight (T):

-

2

-

Name:

-

Plastic recycling and cleaning line

-

After Warranty Service:

-

Video technical supportonline

-

Certification:

-

ISO9001

-

After-sales service provided:

-

Video technical supportonline

-

Main Selling Points:

-

Customization support

-

Advantages:

-

Price Advantage

-

Customized:

-

Customization support

-

color:

-

According to customer needs

-

Human Customer Service:

-

24 hours online answer welcome consultation

-

Material:

-

HQ 304 stainless steel

PRODUCT SPECIFICATIONS

|

Model

|

Capacity

(kg/hr)

|

Installed Power

(KW)

|

Water Supply

(m3/hr )

|

Manpower

(person)

|

Area Required

(L*W*H)

|

|

KD-300

|

300

|

120

|

4-5

|

1-2

|

23mx5mx3.5m

|

|

KD-500

|

500

|

185

|

5-7

|

1-2

|

25mx6mx4.5m

|

|

KD-600

|

600

|

200

|

7-9

|

1-2

|

25mx6mx4.5m

|

|

KD-800

|

800

|

230

|

9-10

|

3

|

32mx6mx4.5m

|

|

KD-1000

|

1000

|

270

|

10-12

|

4

|

40mx6mx5.5m

|

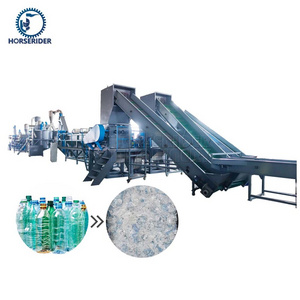

Product Overview

Plastic Recycle Washing Line

The plastic crushing washing drying series is the first treatment for waste plastics

which is the necessary process before plastic granulating This series mainly includes belt conveyor. the crusher,high-speed friction cleaning machine, rinse tank drying machine,etc. It is suitable for soft and hard materials of plastics like pp pe pet hdpe ldpe,etc.

Product Description

PP PE HDPE LDPE waste plastic washing machine floating washing tank floating washer plastic recycling washing line

Material: plastic floating materialsFinished Product: clean plastic flakes

Flake size: 30-40mm or customized

Working Process:

1. Material Conveying → 2. Crushing → 3. Friction Washing and Loading→ 4. Flotation Washing → 5. 2nd Flotation Washing → 6. Lifting and drying machine

Plastic crushing machine

Plastic Conveyor Belt

Plastic washing sink

FEATURES AT A GLANCE

PRODUCT CONFIGURATION

The crusher if for cuttingwastematerials into small scraps.

The high-speedfriction washing machine enables cleansing for 2 timescleaning

the dust off the plastics.

Rinse Tank

Rinse Tank

The rinse tank is welded by Q375 plate which is firm.

The internal fork roller moves the broken

materials forward and precipitatesimpurities

Dewatering Feeder

The feeder adopts the spiral spin-dry method and can remove95%ofthe

moisture saving time and labors.

Hot Searches