- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RICHI Machinery

-

Voltage:

-

380V/415V/440V/480V (Voltage in your country)

-

Dimension(L*W*H):

-

Depends on the specific design

-

Motor Power (Kw):

-

22-280KW For Different Model Wood Pellet Machine

-

Weight (KG):

-

48000 KG

-

Name:

-

Waste Wood Pallet Pellet Making Line

-

Pellet size:

-

6-12mm Customized

-

Capacity:

-

1-100 T/H Customizd Design

-

Motor:

-

SIEMENS Brand

-

Material:

-

Stainless Steel / 40CrMoTi For Core Part

-

Advantage:

-

Long Life Usgae

-

Power Supply:

-

Electric Engine

-

Brand:

-

RICHI MACHINERY

-

Raw material:

-

Waste Wood Pallet, Sawdust, Grass, Straw etc

-

Usage:

-

Make Biomass Pellets For Buring

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1000 - 100000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RICHI Machinery

-

Voltage:

-

380V/415V/440V/480V (Voltage in your country)

-

Dimension(L*W*H):

-

Depends on the specific design

-

Motor Power (Kw):

-

22-280KW For Different Model Wood Pellet Machine

-

Weight (KG):

-

48000 KG

-

Name:

-

Waste Wood Pallet Pellet Making Line

-

Pellet size:

-

6-12mm Customized

-

Capacity:

-

1-100 T/H Customizd Design

-

Motor:

-

SIEMENS Brand

-

Material:

-

Stainless Steel / 40CrMoTi For Core Part

-

Advantage:

-

Long Life Usgae

-

Power Supply:

-

Electric Engine

-

Brand:

-

RICHI MACHINERY

-

Raw material:

-

Waste Wood Pallet, Sawdust, Grass, Straw etc

-

Usage:

-

Make Biomass Pellets For Buring

RICHI BIofuel Usage Waste Wood Pallet Pellet Making Line

Product Overviews

The Process Flow Of The RICHI Wood Pellet Making Line:

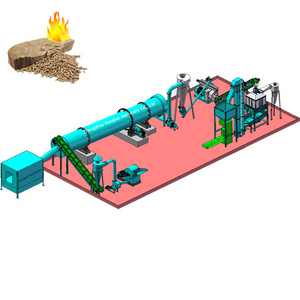

After chipping and crushing the raw materials, Then dry the raw materials to suitable moisture content. Pelletizing by RICHI ring die pellet machine. And through the cooler for cooling. Finally, we use fully automatic bagging and packaging system for packaging.

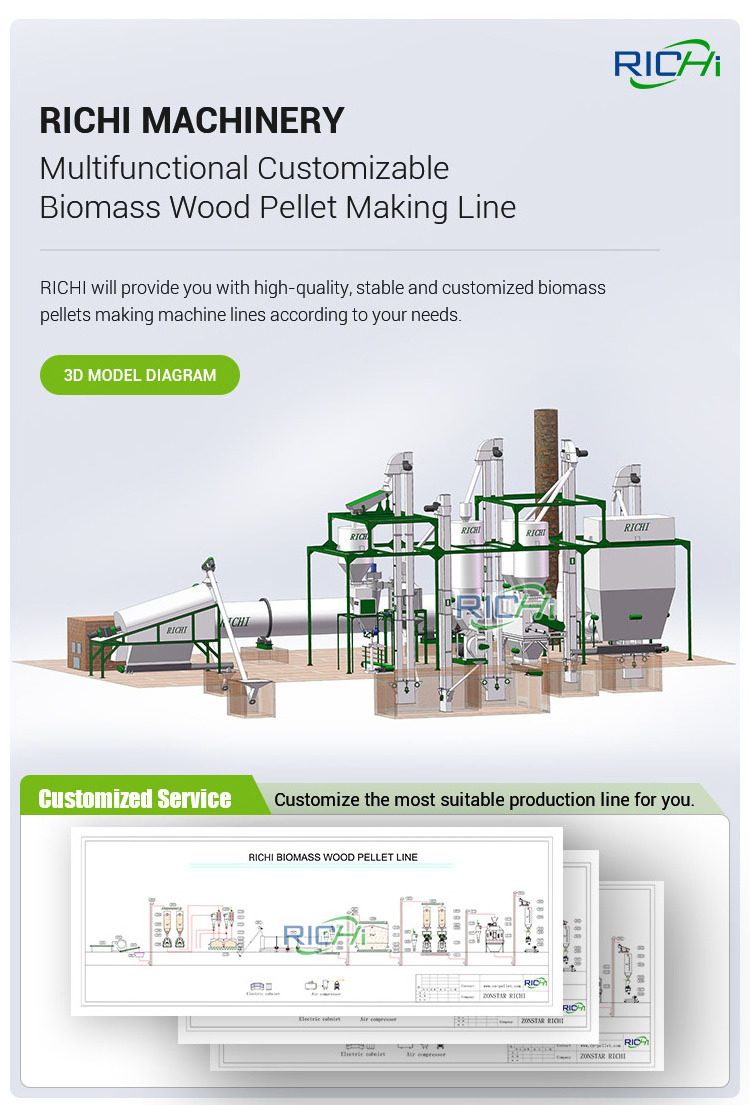

RICHI can customizes the most suitable machine and production line design for you:

As a biomass pellet production line manufacturer with 27 years of experience, relying on our rich technical accumulation, RICHI Machinery will customize the most suitable machine and Wood Pellet Making Line design for you according to your different requirements and actual situation.

Such as the type of raw materials, the size and length of the pellets, the size and height of the site, the climate, local policies, etc.

Such as the type of raw materials, the size and length of the pellets, the size and height of the site, the climate, local policies, etc.

At the same time, RICHI can design and manufacture machines and production lines for you to meet your requirements for the simultaneous production of pellets based on different raw materials.

Pellets And Uses

The Application Scenarios Of Biomass Pellets.

Biomass pellets are made by recycling waste and are a new type of environmentally friendly fuel, widely used in residential heating equipment, power plants, boiler plants, etc. It has the characteristics of large heat generation, low ash content, low environmental pollution, and recyclability.

Detailed Images

In which countries has RICHI Wood Pellet Making Line projects?

RICHI provides biomass pellet production machinery to more than 132 countries and regions. Such as USA, Canada, Australia, Netherlands, Germany, Indonesia, Chile, Poland, Peru, etc. We offer custom designs to our clients..

Advantages

Main Equipment

The Main Equipment Of RICHI Wood Pellet Making Line:

Wood Chipper:

The RICHI Drum Type Wood Chipper can make tree trunks and wood log into wood chips with less than 3~5 cm size . It's an ideal equipment to produce large capacity and good quality wood chips, which is widely used in wood chips

production industry, paper plants, pellet and fiber board plants, etc. The uniquely designed pressure reducing device ensures the long-term stable operation of the equipment.

| Model | Capacity (T/H) | The Diameter of Knife Roll (mm) | The Speed of Knife Roll (rpm) | The Size of Feed lnlet (mm) | Feeding Speeds(m/min) | Main Power(kW) |

| RIGX-215 | 3~5 | 730 | 2 | 400*160 | 38 | 45 |

| RIGX-216 | 8~10 | 600 | 2 | 500*230 | 38 | 55 |

| RIGX-218 | 14~18 | 650 | 2 | 680*300 | 38 | 75 |

Hammer Mill:

The RICHI SFSP Series Hammer Mill can make wood chips into sawdust of 3~5mm . The hammer mill is applied mainly to grinding the raw material to make it suiable to make pellets. The impeller variable frequency feeder is used to ensure work efficiency.

| Model | Rotor Diameter(mm) | Crushing Chamber Width(mm) | Rotating Speed(rpm) | Line Speed Of Hammers(m/s) | Power (kW) | Capacity (t/h) |

| SFSP56*40 | 560 | 400 | 2980 | 88 | 30/37 | 3~6 |

| SFSP66*60 | 660 | 600 | 2980 | 103 | 55/75 | 5~9 |

| SFSP66*80 | 660 | 800 | 2980 | 103 | 90/110 | 8~13 |

| SFSP66*100 | 660 | 1000 | 2980 | 103 | 132 | 12~16 |

| SFSP138*30E | 1380 | 300 | 1440 | 103 | 110/132 | 15~20 |

| SFSP138*40E | 1380 | 400 | 1440 | 103 | 132/160 | 18~25 |

Dryer:

The RICHI Rotary Drum Type Dryer is used to dry materials and remove the moisture. It includes: burning stove to supply hot air to drum dryer, discharging cyclone to efficiently suck out the dried light wood sawdust.

| Model | Diameter (mm) | Length (mm) | Rotating Speed for Drum(rpm) | Capacity (t/h) | lnlet Air Temperature(℃) | Discharge Temperature(℃) |

| 600*6000 | 600 | 6000 | 3~8 | 0.3~0.5 | <700 | 80 |

| 800*8000 | 800 | 8000 | 3~8 | 0.5~0.7 | ≤700 | 80 |

| 1200*12000 | 1200 | 12000 | 3~8 | 1.0~1.2 | <700 | 80 |

| 1500*15000 | 1500 | 15000 | 3~8 | 2.0~2.5 | <700 | 80 |

| 1800*18000 | 1800 | 18000 | 3~8 | 3.0~3.5 | <700 | 80 |

| 2400*10000*3 | 2400 | 10000 | 3~8 | 5 | <700 | 80 |

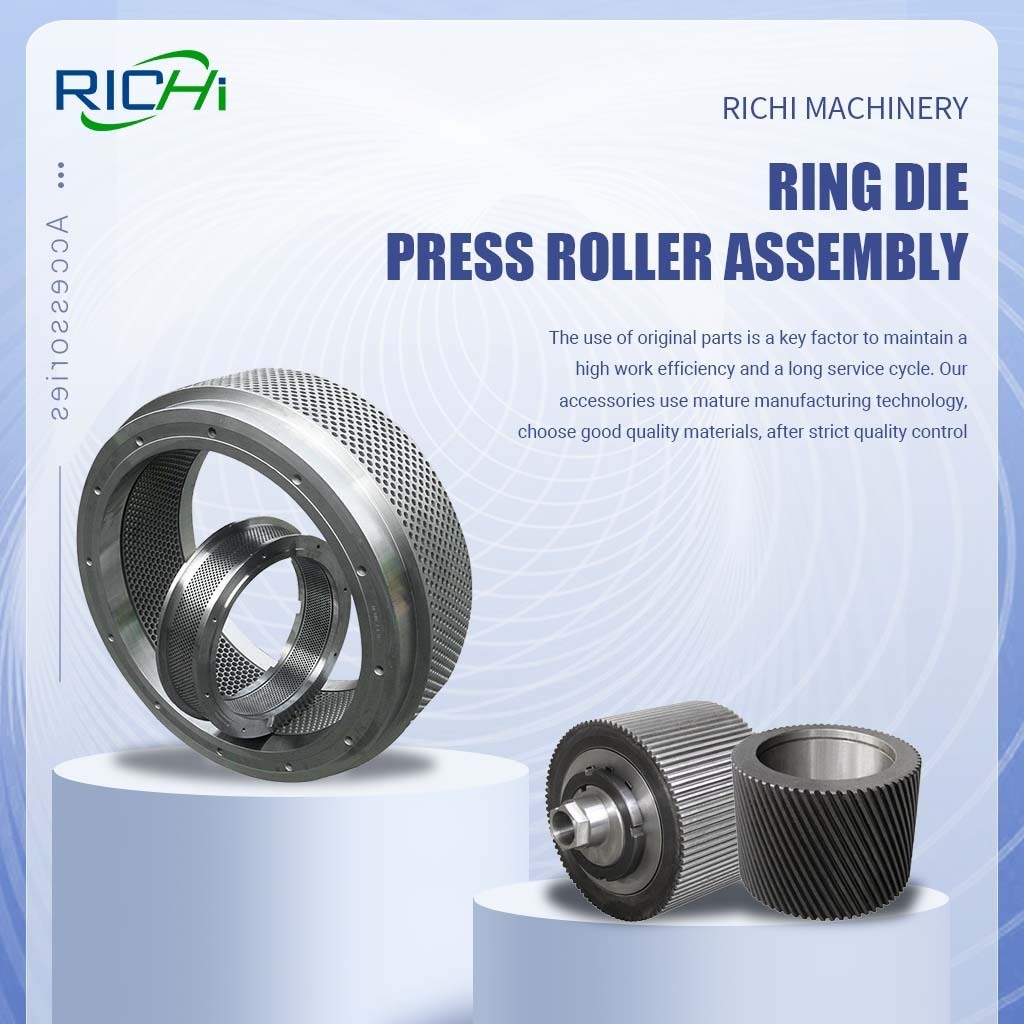

RICHI Multifunctional Biomass Ring Die Sawdust Pelletizer:

As the core machine of the Wood Pellet Making Line, we use stainless steel body, alloy steel ring die and pressure roller, as well as international first-line motors and electrical components to ensure long-term stable operation of the machine.

| Model | Capacity (t/h) | Main Motor Power (kW) | Main Motor Series | Ring Die Diameter (mm) | Finished Pellet Diameter (mm) |

| MZLH320 | 0.3~0.5 | 22 | 6/8P | 320 | 6~12mm |

| MZLH350 | 0.5~0.7 | 37 | 6/8P | 350 | 6~12mm |

| MZLH420 | 0.8~1.5 | 90 | 6/8P | 420 | 6~12mm |

| MZLH520 | 2~2.5 | 132 | 6/8P | 520 | 6~12mm |

| MZLH768 | 2.5~4 | 250 | 6/8P | 762 | 6-~12mm |

| MZLH858 | 4~5 | 280 | 6/8P | 858 | 6~12mm |

Cooler:

When the pellets come out of the pelletizer, the temperature will be around 70~80°C, and then through the RICHI SKLN Series Counterflow Cooler can immediately cool the biomass pellets to room temperature. During the cooling process, the pellets will become hard and compact, and the quality of the pellets will be more stable.

| Model | Capacity (t/h) | Power (kW) | Cooling Time(min) | Suction Air (m³/min) | Temperature Of Material After Cooling |

| SKLN11*11 | 1.5~2 | 0.75 | 6~15 | 750m3/h | Room temperature +3~5℃ |

| SKLN14*14 | 3~5 | 1.5 | 6~15 | 750m3/h | Room temperature +3~5℃ |

| SKLN17*17 | 5~8 | 1.5 | 6~15 | 750m3/h | Room temperature +3~5℃ |

| SKLN20*20 | 9~12 | 1.5 | 6~15 | 750m3/h | Room temperature +3~5℃ |

| SKLN24*24 | 13~18 | 1.5 | 6~15 | 750m3/h | Room temperature +3~5℃ |

Automatic Pellet Package System:

RICHI Automatic Pellet Package System has automatic weighing, quantitative filling, sewing and other functions. It is suitable for packaging bags of different specifications and materials of 10~1000Kg.

| Model | Application | Feeding Method | Speed (bags/min) | Powder (kW) | Precision | Temperature Range(℃) |

| DCS-C50/D | Pellet | Gravity | 6~8 | 1.1 |

Static±0.1%

Dynamic±0.2% |

-10~40 |

| DCS-A50/D | Powder | Screw | 6~8 | 3 |

Static±0.1%

Dynamic±0.2% |

-10~40 |

| DCS-B50/D | Pellet/Powder | Belt | 6~8 | 3 |

Static±0.1%

Dynamic±0.2% |

-10~40 |

| DCS-B50/S | Pellet/Powder | Belt | 10~12 | 3 |

Static±0.1%

Dynamic±0.2% |

-10~40 |

| DCS-A50/Y | Premix | Screw | 6~8 | 3 |

Static±0.1%

Dynamic±0.2% |

-10~40 |

About RICHI

Can I learn more about RICHI?

Headquartered in Zhengzhou of central China's Henan Province, RICHI Machinery is an industrial group mainly specialized in biomass pellet machinery, and also covers some other strategic businesses such as feed pellet energy machinery, organic fertilizer pellet machinery, parts and components, and so on.

RICHI owns a sound sales system and complete sales service network, and its products are sold all over the country and overseas in more than 109 countries and regions. At present, the international strategy is implemented stably, Richi has 21 overseas agents, as well as 1 overseas subsidiary in Uzbekistan.

In the future, RICHI will always strive to enhance its core technology and international competitiveness to become a sustainable pellet machinery manufacturer.

What certificate does RICHI have?

With a deep commitment towards quality, we bring forth products having impeccable standards. We perform production processes with superior quality material and electrically advanced components. Tested on several parameters, our product range ensures longer service life and efficient performance. The company has passed the IS02008 quality management system certification, CE certification, etc.

RICHI's pellet production line has been exported to more than 132 countries such as America, Canada, Mexico, England, Poland, Netherlands, Germany, Uzbekistan, South Africa, Kenya,Tanzania, Algeria, Morocco, Sudan, Saudi Arabia, Australia, Malaysia, Indonesia, Philippines, etc.

Want to know the operation status of the project in your country as a reference? Please feel free to contact us. We will serve you 24/7.

FAQ

Q: Are you a trading company or a manufacturer?

We are a manufacturer, which has more than 26 years of experience in this industry.

Q: Where is your factory? Can I visit it?

Of course, we welcome customers to visit our factory. We are located in Kaifeng City, Henan Province, China. And we have a technology research and development center in Zhengzhou City.

Q: What is the use of biomass wood pellets?

As a new type of energy, biomass wood pellets are mainly used for combustion to provide heat energy. It has the characteristics of high calorific value, low ash content, and environmental friendliness.

Q: Which raw materials can be made into biomass pellets?

This production line can process a lot of raw materials, forestry wastes such as logs, branches, trunks, planks, roots, and other types of wood. Construction waste such as wooden pallets, templates, wooden frames, etc. Agricultural wastes such as straw and pasture.

Q: I know little about the pellet production line, how can I choose the most suitable machine?

Just tell us your raw materials, your capacity (t/h), and the size of the final pellet product, and we will select the machine for you according to your specific situation.

Q: What brand is your motor and bearing?

We use German Siemens motors and SKF brand bearings.

Q: Can I use this machine to produce multiple-size pellets?

Yes, RICHI's wood pellet machine is multi-functional. Our machine can produce wood pellets of various sizes, it is usually 6/8/10/12mm.

Q: Our worker can not know how to operate the pellet machine, what should I do?

Our engineers will guide workers on-site on how to install machines and build workshops. Then our engineers will test run the

production line on-site and train your workers on how to operate it.

Q: In which countries do you have projects?

Our products are exported to more than 132+ countries such as America, Canada, Australia, Mexico, England, Uzbekistan, South Africa, Kenya, Tanzania, Algeria, Morocco, Sudan, Saudi Arabia, Australia, Malaysia, Indonesia, Philippines, etc.

We are a manufacturer, which has more than 26 years of experience in this industry.

Q: Where is your factory? Can I visit it?

Of course, we welcome customers to visit our factory. We are located in Kaifeng City, Henan Province, China. And we have a technology research and development center in Zhengzhou City.

Q: What is the use of biomass wood pellets?

As a new type of energy, biomass wood pellets are mainly used for combustion to provide heat energy. It has the characteristics of high calorific value, low ash content, and environmental friendliness.

Q: Which raw materials can be made into biomass pellets?

This production line can process a lot of raw materials, forestry wastes such as logs, branches, trunks, planks, roots, and other types of wood. Construction waste such as wooden pallets, templates, wooden frames, etc. Agricultural wastes such as straw and pasture.

Q: I know little about the pellet production line, how can I choose the most suitable machine?

Just tell us your raw materials, your capacity (t/h), and the size of the final pellet product, and we will select the machine for you according to your specific situation.

Q: What brand is your motor and bearing?

We use German Siemens motors and SKF brand bearings.

Q: Can I use this machine to produce multiple-size pellets?

Yes, RICHI's wood pellet machine is multi-functional. Our machine can produce wood pellets of various sizes, it is usually 6/8/10/12mm.

Q: Our worker can not know how to operate the pellet machine, what should I do?

Our engineers will guide workers on-site on how to install machines and build workshops. Then our engineers will test run the

production line on-site and train your workers on how to operate it.

Q: In which countries do you have projects?

Our products are exported to more than 132+ countries such as America, Canada, Australia, Mexico, England, Uzbekistan, South Africa, Kenya, Tanzania, Algeria, Morocco, Sudan, Saudi Arabia, Australia, Malaysia, Indonesia, Philippines, etc.

Contact RICHI

How to contact RICHI to get pictures, videos, and quotations?

Please leave your message in the text box below to send an inquiry to RICHI.

Or click the "

Contact Supplier

" or "

Chat Now

" button to contact us online.

Please remember to agree to share your contact information with us.

RICHI BIofuel Usage Waste Wood Pallet Pellet Making Line

Hot Searches