- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Cold Chamber Die Casing Machine

-

Name:

-

Sand Molding Machine Automatic

-

Usage:

-

Foundry Pieces

-

Material:

-

Iron Steel

-

Feature:

-

High Efficency

-

Technology:

-

Automatic Mold Adjustment

-

Raw material:

-

Copper Cathode

-

Machine color:

-

Custromized

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Product name:

-

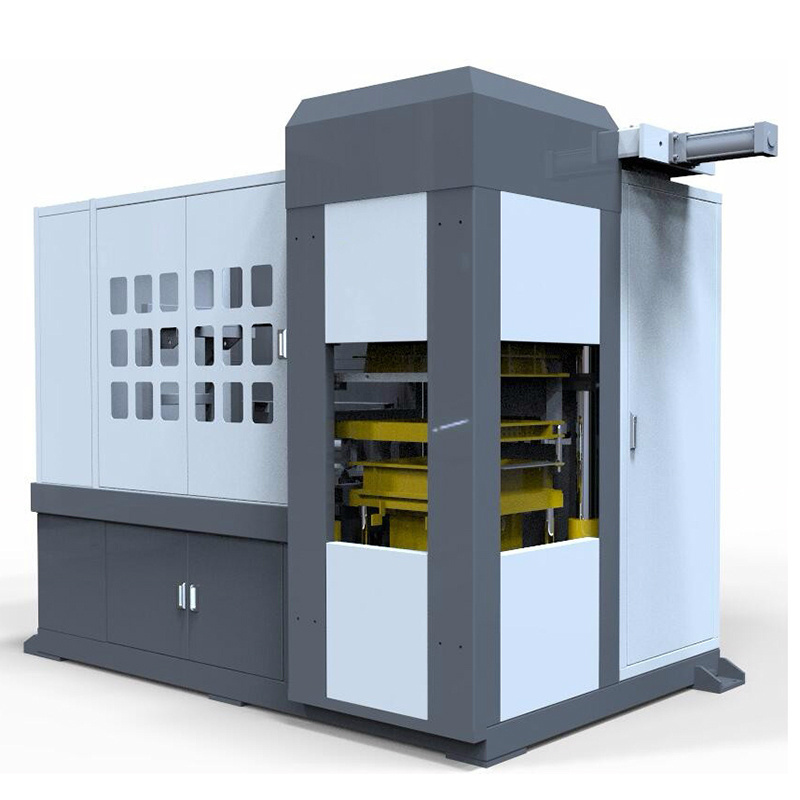

factory introduce Foundry Machine Foundry Clay Sand Molding Machine

-

Application:

-

Casting Industries

-

Type:

-

Cold Chamber Die Casing Machine

-

Name:

-

Sand Molding Machine Automatic

-

Usage:

-

Foundry Pieces

-

Material:

-

Iron Steel

-

Feature:

-

High Efficency

-

Technology:

-

Automatic Mold Adjustment

-

Raw material:

-

Copper Cathode

-

Machine color:

-

Custromized

Low pressure casting machine features:

There are two types of low pressure casting machine: top-injection low pressure casting machine and side-injection low pressure casting machine.

Top-injection low-pressure casting machine is widely used. Its characteristics are simple structure, easy manufacture, easy operation, but low productivity. Side-injection low-pressure casting machine is characterized by the casting mould placed on the side of the heat preservation furnace. The two parts are connected by lifting pipes (the same fixed connection and the non-fixed connection). The productivity is high, but the structure is complex. The low pressure casting equipment is composed of heat preservation furnace and accessories, mould opening and closing system and gas supply system.

Metal mould gravity casting machine can be divided into two categories: tilting gravity casting machine and fixed gravity casting machine. The tilting gravity casting machine can realize the tilting casting of the mould and improve the internal quality of the castings effectively. It is especially suitable for gravity casting of complex castings such as intake manifold.

Centrifugal casting machine is characterized by filling and solidification of liquid metal under centrifugal force, good metal feeding effect, compact casting structure and good mechanical properties; hollow casting does not need gating riser, metal utilization rate can be greatly improved. Therefore, centrifugal casting is a material-saving, energy-saving and high-efficiency process for certain specific shape castings, but special attention should be paid to taking effective safety measures.

Aluminum ingot casting machine solves the problems of easy stratification and falling off caused by the lax wrapping of iron particles by aluminium, and effectively improves the working efficiency of casting, wrapping iron particles and demoulding of aluminium ingot, and improves the quality of products, so that it can fully meet the quality requirements of aluminium ingot in steelmaking production. The casting machine has the advantages of simple structure, convenient operation, fast operation, no occupation of land and easy movement. It can effectively reduce the labor intensity of workers and improve the working environment.