- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v 50hz(customizable)

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

Oxygen system:3100*1300*2400

-

Marketing Type:

-

Hot Product 2020

-

Name:

-

PSA Oxygen Generator

-

Capacity:

-

5~200Nm3/h

-

Pressure:

-

0.01~0.4Ppa(Adjustable)

-

Dew point:

-

-40℃~-60℃

-

Adsorption mode:

-

Two tower pressure swing adsorption

-

Certification:

-

ISO 13485:2016

-

Purity:

-

93+/-2%

-

Pressure of outlet O2:

-

≥0.5Mpa

-

Start-up time:

-

≤30min

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Tuowei

-

Production Rate:

-

100%

-

Voltage:

-

220v 50hz(customizable)

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

Oxygen system:3100*1300*2400

-

Marketing Type:

-

Hot Product 2020

-

Name:

-

PSA Oxygen Generator

-

Capacity:

-

5~200Nm3/h

-

Pressure:

-

0.01~0.4Ppa(Adjustable)

-

Dew point:

-

-40℃~-60℃

-

Adsorption mode:

-

Two tower pressure swing adsorption

-

Certification:

-

ISO 13485:2016

-

Purity:

-

93+/-2%

-

Pressure of outlet O2:

-

≥0.5Mpa

-

Start-up time:

-

≤30min

1.Specification of industrial PSA oxygen generator

| oxygen capacity | 5-200 Nm3/h |

| oxygen purity | 93%±2 |

| output pressure |

0.3-0.6MPa(3-6Bar) adjustable

15MPa or 20Mpa filling pressure offered |

PSA O2 generators (for medical, hospital use, with sterilization filter, deodorization filter and necessary pipes)

| Model | O2 flow | O2 purity | O2 outlet pressure | Motor power of matching screw air compressor | Air consumption |

| m3/h | % | bar | kW / 8bar | ≥ m3/min | |

| SPO93-5 | 5 | 93±2 | 3-6 (inlet compressed air at 8bar) | 7.5 | 1.08 |

| SPO93-10 | 10 | 15 | 2.17 | ||

| SPO93-20 | 20 | 30 | 4.33 | ||

| SPO93-30 | 30 | 45 | 6.5 | ||

| SPO93-40 | 40 | 55 | 8.7 | ||

| SPO93-50 | 50 | 75 | 10.83 | ||

| SPO93-60 | 60 | 90 | 13 | ||

| SPO93-70 | 70 | 110 | 15.17 | ||

| SPO93-80 | 80 | 110 | 17.33 | ||

| SPO93-90 | 90 | 110 | 19.5 | ||

| SPO93-100 | 100 | 132 | 21.7 | ||

| SPO93-120 | 120 | 160 | 26 | ||

| SPO93-150 | 150 | 220 | 32.5 | ||

| SPO93-180 | 180 | 250 | 39 | ||

| SPO93-200 | 200 | 250 2-stages compression | 43.3 |

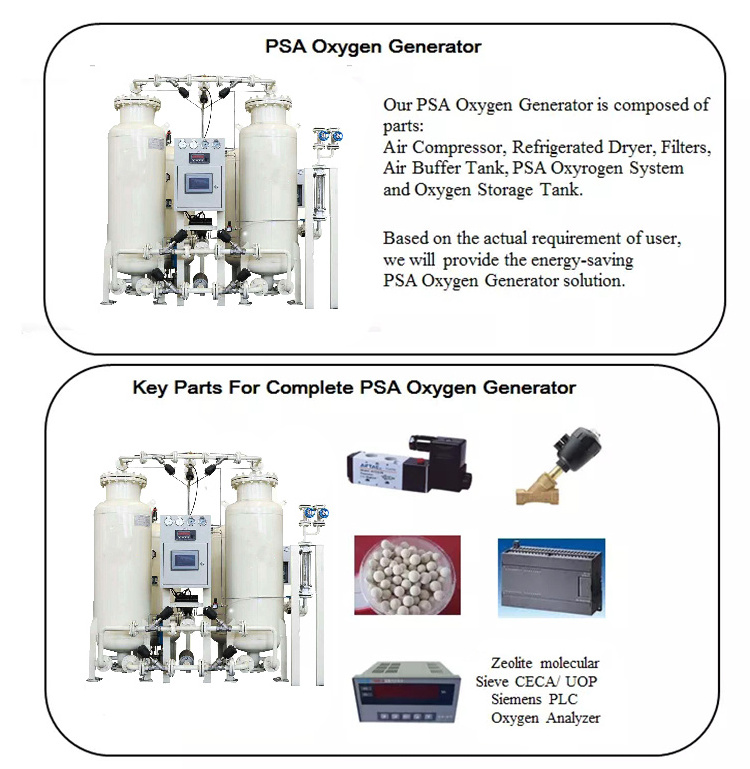

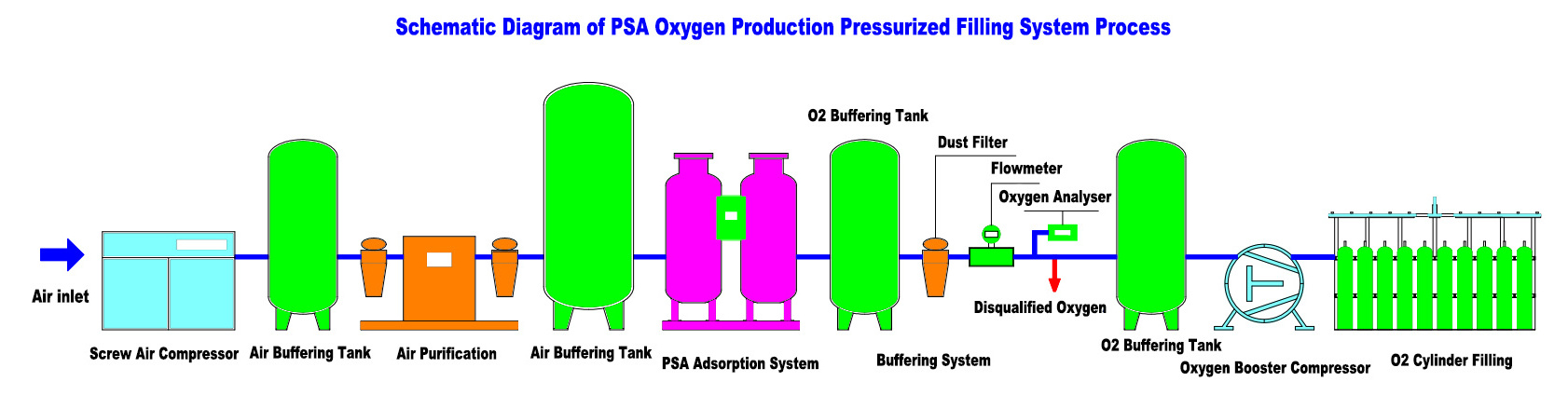

2. PSA Oxygen Generator Process Flow Brief Description

Oxygen Equipment working principle: The use of molecular sieve physical adsorption and desorption technology. The oxygen-making machine is filled with molecular sieve, which can adsorb nitrogen in the air when it is pressurized. The remaining non-absorbed oxygen is collected and purified to become high-purity oxygen. When the molecular sieve is decompressed, the adsorbed nitrogen is discharged back into the ambient air, and when the next pressure is applied, the nitrogen can be adsorbed and oxygen can be produced. The medical oxygen-producing equipment adopts the world advanced PSA (pressure swing adsorption) air separation and oxygen-producing technology, which realizes the separation of oxygen and nitrogen based on the difference of the adsorption ability of the adsorbent (zeolite molecular sieve) to the oxygen and nitrogen in the air. When the air enters the bed which contains the adsorbent, the nitrogen adsorption ability is strong, but the oxygen is not adsorbed, thus may obtain the high density oxygen at the adsorption bed outlet. Because the adsorbents have the characteristic that the amount of adsorbents changes with the pressure, the adsorption and desorption can be carried out alternately by changing the pressure.

3.Oxygen Generator Technical Features

1).Full Automation

All systems are designed for un-attended operation and automatic oxygen demand adjustment.

2).Lower Space Requirement

The design and Instrument makes the plant size very compact,assembly on skids,prefabricated from factory.

3).Fast Start-up

Start-up time is only 5 minutes to get desired oxygen purity.So these units can be switched ON&OFF as per Nitrogen demand changes.

4).High Reliabiity

Very reliable for continuous and steady operation with constant oxygen purity.Plant availability time is better than 99% always.

5).Molecular Sieves life

Expected Molecular sieves life is around 15-years i.e. whole life time of oxygen plant.

6).Adjustable

By altering flow,you can deliver oxygen with precisely the right purity