- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei

-

Brand Name:

-

PUTAI

-

Voltage:

-

380/415/460

-

Power:

-

7.5kw/11kw

-

Dimension(L*W*H):

-

6500mm*1200mm*1650m

-

Weight:

-

4300 kg

-

Cutting blade material:

-

Cr12

-

Material Thickness:

-

0.4---0.8 Mm

-

Control system:

-

servo cutting

-

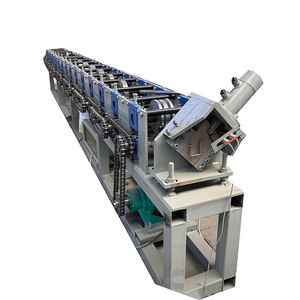

Roller station:

-

16 Stations

-

Product name:

-

metal track profile machine

-

Roller material:

-

Cr12

-

After-sales Service Provided:

-

Engineers

-

Machine Type:

-

high speed CU drywall profile

-

Profiles:

-

drywall system stud

-

Shaft material:

-

45# Steel Forging Treatment

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Work Pressure:

-

12 MPa

-

Production Capacity:

-

100m/min

-

Place of Origin:

-

Hebei

-

Brand Name:

-

PUTAI

-

Voltage:

-

380/415/460

-

Power:

-

7.5kw/11kw

-

Dimension(L*W*H):

-

6500mm*1200mm*1650m

-

Weight:

-

4300 kg

-

Cutting blade material:

-

Cr12

-

Material Thickness:

-

0.4---0.8 Mm

-

Control system:

-

servo cutting

-

Roller station:

-

16 Stations

-

Product name:

-

metal track profile machine

-

Roller material:

-

Cr12

-

After-sales Service Provided:

-

Engineers

-

Machine Type:

-

high speed CU drywall profile

-

Profiles:

-

drywall system stud

-

Shaft material:

-

45# Steel Forging Treatment

Product Description

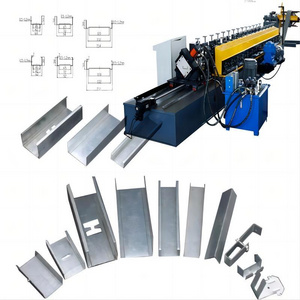

Metal Drywall Studs Track Roll Forming Machine Light Gauge Steel Framing Machine

track profile 100

stud profile 50

track 75

Project case

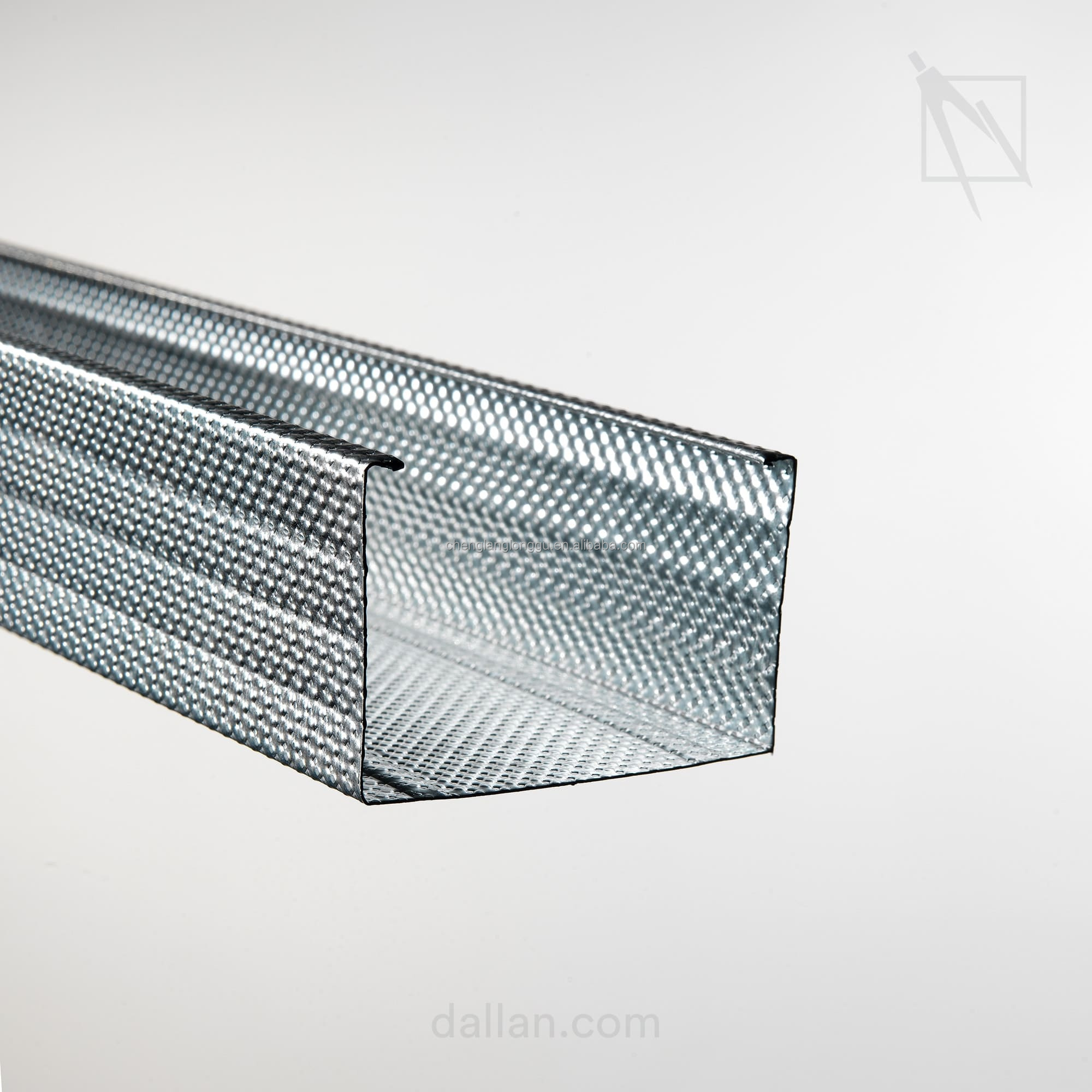

Drywall stud and track profiles CW/UW/CD/UD are a type of metal framing system typically used in the construction industry to create walls and ceilings. They come in a variety of shapes and sizes, but usually consist of strong galvanized steel tracks and studs.

The track and stud profile is commonly used for interior walls, but can also be used for ceilings and exterior walls. They offer several benefits compared to traditional wooden framing systems, including greater strength, fire resistance, durability, and ease of installation.

Detailed Images

Product detail drawing

|

1.Roller

|

2.Servo Cutting System

|

3.Straightening Part

|

|

Cr12 (also known as D3) steel is a high-carbon, high-chromium steel alloy used in the production of rollers for various

applications, including the manufacturing of asymmetrical sectional steel, round steel, and flat steel. Cr12 steel is known for its high wear resistance, toughness, and strength, making it an ideal material for roller production. used for roll forming machine |

A servo cutting system is a type of cutting system used in production processes that involves the use of servo motors to control cutting operations. The servo motors are equipped with sensors that provide feedback to the system on the position and movement of the material being cut. This allows for precise, rapid, and consistent cuts to be made with minimal waste, resulting in improved

productivity and reduced costs. |

The process of straightening parts involves applying a force to the part at a precise location to bend it back to its original

form. This force needs to be applied gradually and evenly to avoid cracking or further distortion of the material. |

Product Presentation

|

Product Name

|

Drywall Profile roll forming machine

|

|

Material

|

GI/PPGI/GL/PPGL

|

|

Power

|

16.5KW

|

|

|

220V/380V/415V

According to the customer's national industrial voltage

|

|

Type

|

high speed roll forming machine

|

|

Model

|

Drywall Stud and Track

|

|

Roller

|

14Rows-16Rows

|

|

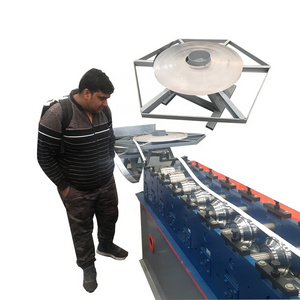

Decoiler type

|

load-bearing

|

Advantage

|

|

Manually deociler

|

1.5t/2.5t

|

Economical applicability(order machine free for you )

|

|

Hydrualic deociler

|

3t/5t

|

Hydraulic automatic tightening (powerful to loasing steel than manual)

|

|

Double Arm decoiler

|

2t+2t/3t+3t

|

Changing materials is faster and easier(for high speed machine to produce the profile)

|

Manually deociler

Hydraulic Decoiler

Double arm decoiler

Related Product

Certificate

Our R & D team has won a number of patent certificates and quality outstanding brand awards

Company Introduction

Our company Bazhou chenglang factory and Putai company(Tianjin Branch) is a professional cold roll forming machine manufacturer,we have been focusing on this field for 23 years. Our equipment includes roof forming machine, floor deck machine, automatic hydraulic uncoiler machine, shutter door coiling machine, light keel cold roll forming machine,stud and track C Z U forming machine, whole equalizer machine and other related construction equipment. With more than 22 years of engineering and design research and develop team. We have two patents for independently developed machine .At the same time, our machines use brand electrical components, raw materials from brand steel mills, strict process control, two year warranty, installation and training services. Our customers all over the world, such as Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other countries and regions. We have rich experience in different country needs such as profiles, thickness ranges, use, installation etc.

Company tenet: technological innovation, customer - centered, win-win. Thank you for your trust and choice, we will provide you with the best service support, help you achieve greater success. We look forward to more cooperation with old and new friends from all over the world!

Company tenet: technological innovation, customer - centered, win-win. Thank you for your trust and choice, we will provide you with the best service support, help you achieve greater success. We look forward to more cooperation with old and new friends from all over the world!

Client Feedback

Packing&Shipping

FAQ

1-Are you manufacturer or trading company?

Yes, and we have more than 33 years of the cold roll forming machine

2-Can the machine parts be changed according to my requirements?

Yes, we will try our best to give you the best products.

3-What is your payment term?

30% T/T deposit paid in advance, 70% balance paid before shipping.

4-What is the delivery time?

About 35days after receive the deposit.

5- How can I get to your factory?

We could pick you up in airport or high speed rail station. The nearest airport is Beijing Daxing airport or Tianjin airport, and the nearest station is Bazhou or Shengfang station,please contact us.

6- What service can you provide before order?

About the pre-sale service. We provide you answers of all your questions on our machines,such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

7- Can you finish the machine during the delivery time?

We will finish the machine in time according to determined lead time

8-Can you provide some spare parts?

Yes. The quick-wear parts are sent to you together with the roll forming machine

Hot Searches