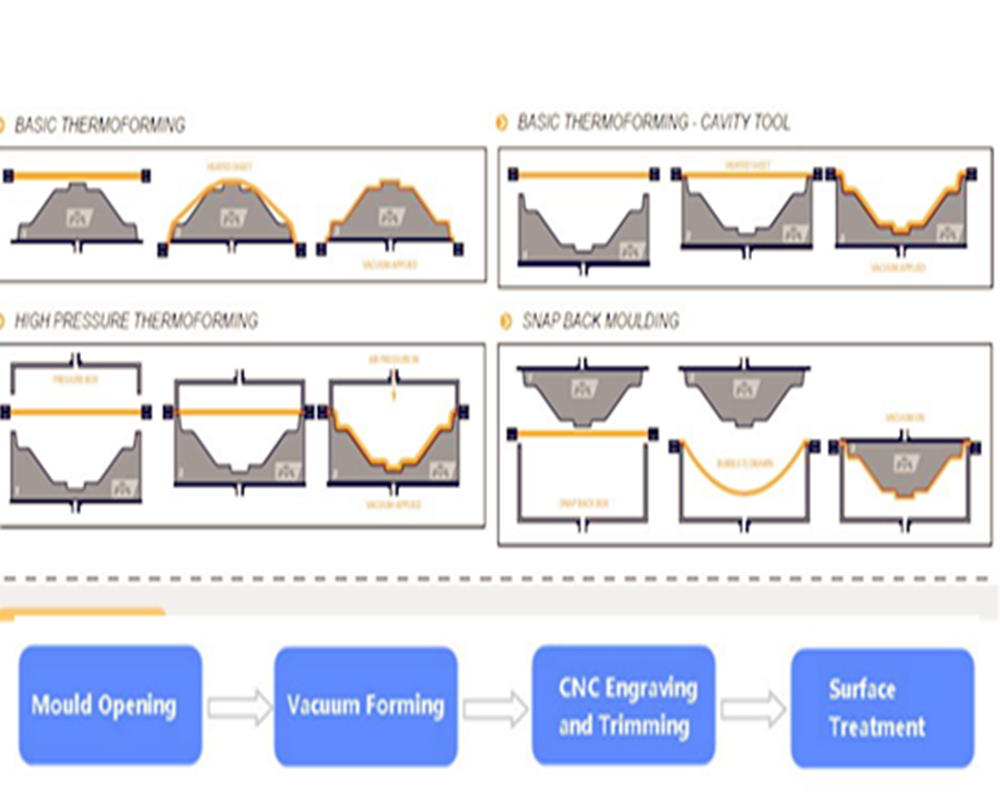

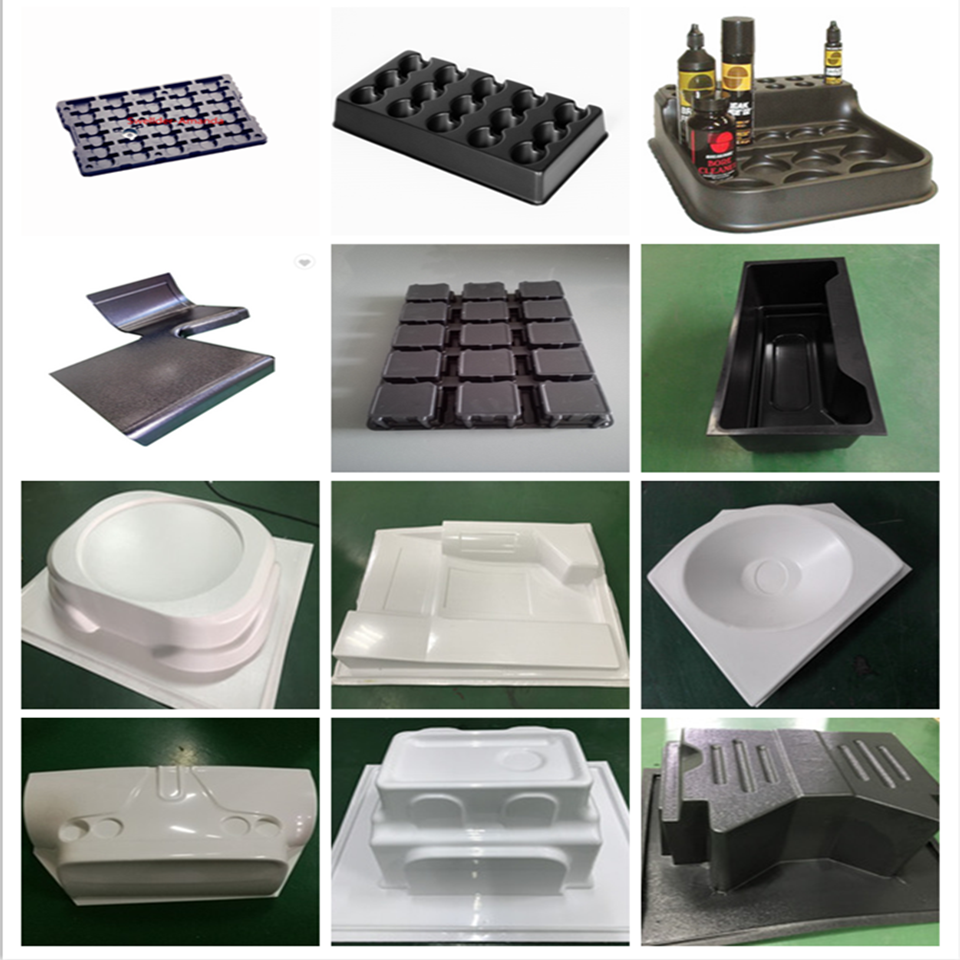

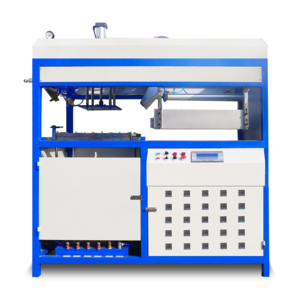

High quality ABS large plastic vacuum formed square water tray can't be produced without reliable manufacturing tools and effective production process. We will purchase the high quality raw materials and put them into production. using the latest technology, we heat to a high temperature to make the materials softening with the large vacuum forming machines and the moulds.

Offering the customized products is our advantages,so

You provide your ideas and we offer all kinds of

satisfactory products

:Just give us your drawings or give your samples,we provide you with high quality product and competitive price.We provide design to delivery with one-stop service.