- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Summit

-

Model Number:

-

HA50

-

Torque:

-

\

-

Max Dynamic Load:

-

8000N

-

Max Static Load:

-

13000N

-

Max Stroke:

-

350mm

-

Installation distance:

-

Max 500mm

-

Orifice:

-

A/B

-

Input Voltage:

-

12V/24V/36V48VDC

-

Speed at no load:

-

16mm/s

-

Temperature:

-

-20℃~65℃

-

IP Grade:

-

IP65

-

Pump press:

-

7.1MPa

Quick Details

-

Speed(RPM):

-

5000rpm

-

Continuous Current(A):

-

Max 30A

-

Efficiency:

-

IE 1

-

Warranty:

-

2 years

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Summit

-

Model Number:

-

HA50

-

Torque:

-

\

-

Max Dynamic Load:

-

8000N

-

Max Static Load:

-

13000N

-

Max Stroke:

-

350mm

-

Installation distance:

-

Max 500mm

-

Orifice:

-

A/B

-

Input Voltage:

-

12V/24V/36V48VDC

-

Speed at no load:

-

16mm/s

-

Temperature:

-

-20℃~65℃

-

IP Grade:

-

IP65

-

Pump press:

-

7.1MPa

Products Description

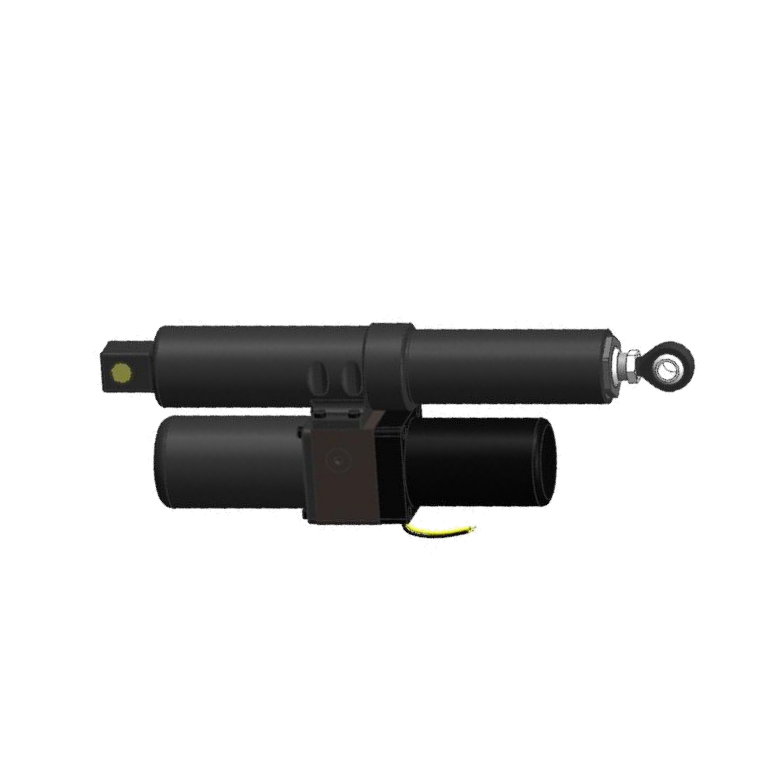

Electric-hydraulic linear actuator

HA50

The electro-hydraulic push rod is a hydraulic linear reciprocating actuator that integrates a DC motor, a hydraulic pump, a valve,

and a cylinder.It has small size, convenient installation and integrated advantages that can not be compared with conventional

hydraulic products.

and a cylinder.It has small size, convenient installation and integrated advantages that can not be compared with conventional

hydraulic products.

Features

1. Miniature DC permanent magnet motor, small size, easy to install

2. Hydraulic transmission, stable operation and impact resistance

3. Reciprocating motion; maximum thrust 8000N; maximum static load 13000N

4. No-load linear speed 16mm/s

5. Optional -20 ° C ~ 65 ° C environment configuration.

6. Fully enclosed hydraulic system, reliable, maintenance free.

7. Compact structure, no external pipeline, environmental protection and no pollution.

8. IP Grade IP65

9. Widely used in all kinds of industrial automation equipment, engineering vehicles and environmental protection, agricultural

machinery and other places that need to be driven.

2. Hydraulic transmission, stable operation and impact resistance

3. Reciprocating motion; maximum thrust 8000N; maximum static load 13000N

4. No-load linear speed 16mm/s

5. Optional -20 ° C ~ 65 ° C environment configuration.

6. Fully enclosed hydraulic system, reliable, maintenance free.

7. Compact structure, no external pipeline, environmental protection and no pollution.

8. IP Grade IP65

9. Widely used in all kinds of industrial automation equipment, engineering vehicles and environmental protection, agricultural

machinery and other places that need to be driven.

Specifications

|

Max Dynamic Load

|

|

4000N/6000N/8000N

|

|

||

|

Max Static Load

|

|

13000N

|

|

||

|

Stroke(mm)

|

|

150/200/250/300/350

|

|

||

|

Installation distance(mm)

|

|

300/350/400/450/500

|

|

||

|

Orifice

|

|

A/B

|

|

||

|

Input Voltage

|

|

12/24/36/48VDC

|

|

||

|

Speed at no load

|

|

16mm/s

|

|

||

|

Temperature

|

|

-20℃~65℃

|

|

||

|

IP Grade

|

|

IP65

|

|

||

|

Pump press

|

|

7.1MPa

|

|

||

|

Pump duty

|

|

0.33ml/rpm

|

|

||

|

Cylinder Diameter

|

|

φ38

|

|

||

Selection of Throttle Hole

1. Throttle holes are needed on the reflux side when the cylinder shakes due to the drop of dead weight.

2. Choose throttle orifices at port A or B according to the load on the cylinde.

3. The purpose of throttle orifice is to have the same direction force of load and prevent running jitter.

2. Choose throttle orifices at port A or B according to the load on the cylinde.

3. The purpose of throttle orifice is to have the same direction force of load and prevent running jitter.

Load Form

Throttling aperture

Examples: 6 kN Compressed Load Choosing_0.6 Throttle Hole

Advantages

1. No additional hydraulic workstations required

2. Simply install the pin and electrical wiring at both ends of the cylinder during installation.

3. Since the DC motor and the hydraulic parts are all sealed, no oil leakage and in-cylinder water ingress will occur.

4. Hydraulic work has smooth movement and is suitable for installation with vibration mechanism

5. The reliability of the load can be maintained by a controllable check valve

6. Prevent overload by overflow valve and avoid motor damage due to load

1. No additional hydraulic workstations required

2. Simply install the pin and electrical wiring at both ends of the cylinder during installation.

3. Since the DC motor and the hydraulic parts are all sealed, no oil leakage and in-cylinder water ingress will occur.

4. Hydraulic work has smooth movement and is suitable for installation with vibration mechanism

5. The reliability of the load can be maintained by a controllable check valve

6. Prevent overload by overflow valve and avoid motor damage due to load

Details Images

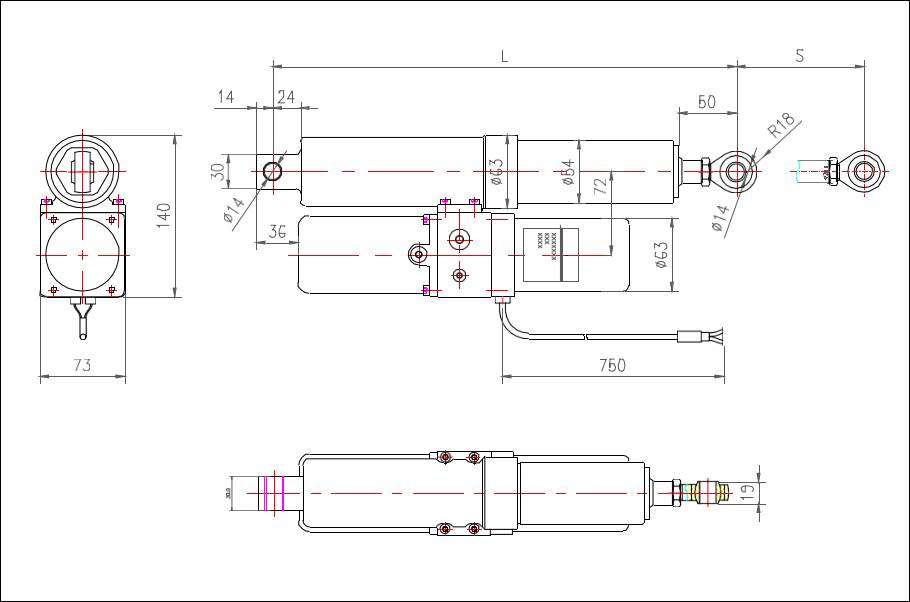

Dimension

Performance

Related Products

Hot Searches