- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Polypropylene filter cartridge pleated for industrial powder

-

Type:

-

circular size filter cartridge

-

Filtration direction:

-

Surface filter

-

Length:

-

300 - 6000mm

-

Diameter:

-

115 - 600 mm

-

Dust cleaning type:

-

Pulse jet clean

-

Product application:

-

Nomal temperature dustt collection waterproof

-

Working temperature:

-

130 degree

-

Certificate:

-

ISO

Quick Details

-

Core Components:

-

none

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CNP

-

Product name:

-

Polypropylene filter cartridge pleated for industrial powder

-

Type:

-

circular size filter cartridge

-

Filtration direction:

-

Surface filter

-

Length:

-

300 - 6000mm

-

Diameter:

-

115 - 600 mm

-

Dust cleaning type:

-

Pulse jet clean

-

Product application:

-

Nomal temperature dustt collection waterproof

-

Working temperature:

-

130 degree

-

Certificate:

-

ISO

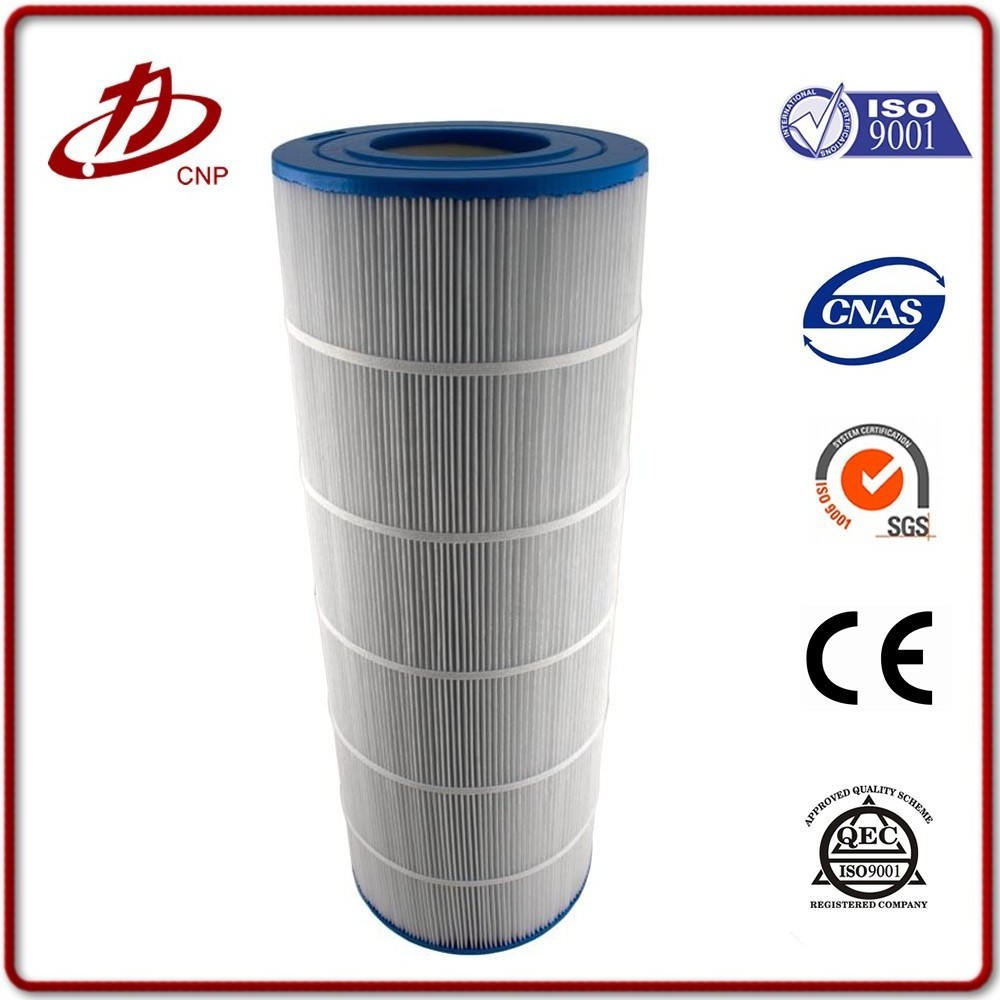

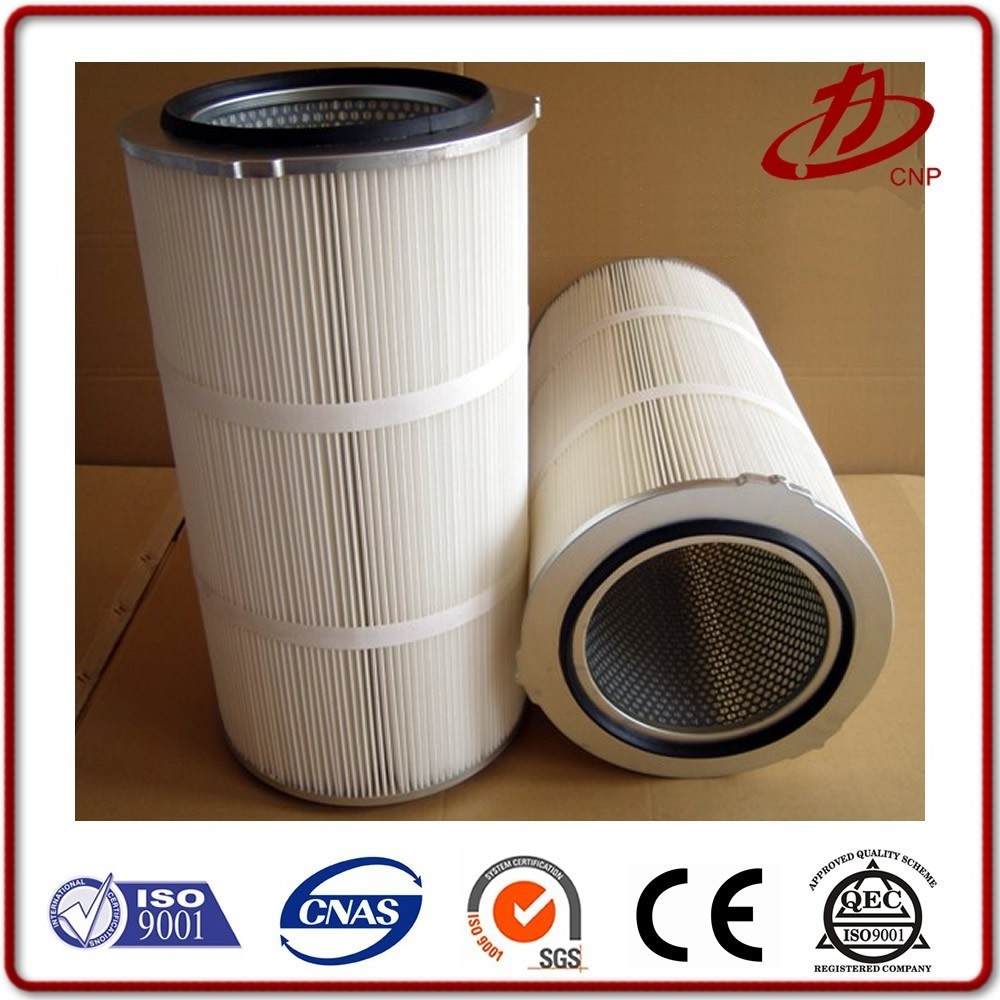

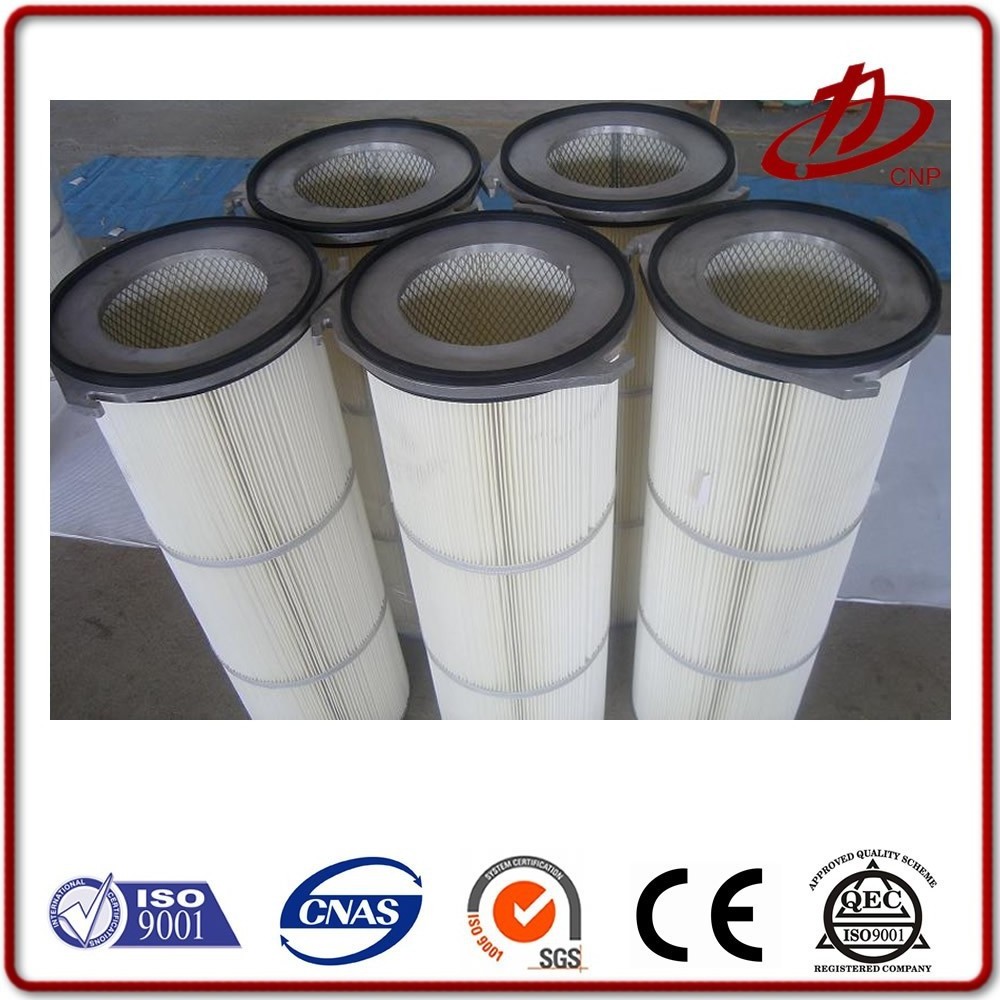

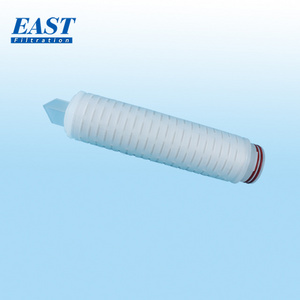

Polypropylene filter cartridge pleated for industrial powder filteration

1. long work life

2. High dust collection efficiency

3. Many types of material can suit for many industry and dedusting cases

Polypropylene filter cartridge pleated for industrial powder filteration

INTRODUCTION

Filter cartridge is a kind of common dust catching device. The characteristic is: high capture rate, small resistance, easy to into the flue, etc. They are widely used for particulate matter, food and beverage industry lampblack, asphalt smoke pollutants such as sampling, chromium acid fog, acid mist.

According to the material, it can be divided into glass fibre filter cylinder and corundum filter cartridge, daily application is the most widely glass fibre filter cylinder. Glass fibre filter cylinder made of super fine glass fiber to 0.5 mu m above dust capture rate can reach more than 99.9%. But due to the production process, some cartridge quality problems, affects the efficiency of capture, in gas monitoring, the sampling error analysis on monitoring results is greater than the influence.

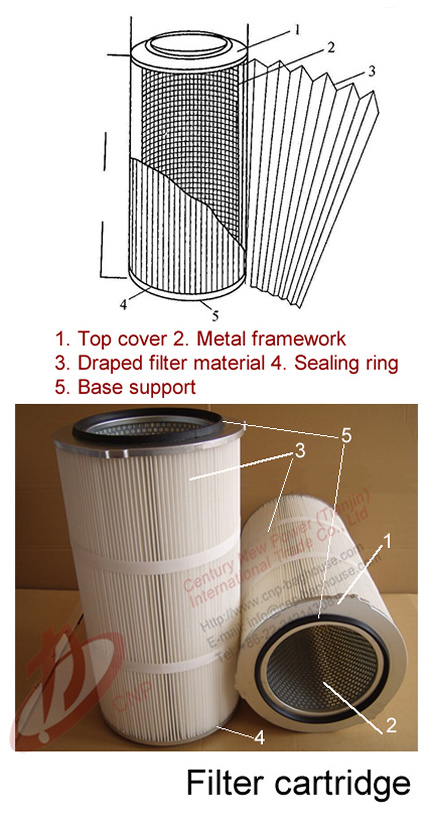

Structure and application

The structure of the filter cartridge, it often has the top cover, metal framework, folded filter material and base parts, etc. Filter cartridge is calculating the length of the filter material folded into fold, fore and aft adhesive to drum. The drum internal is supported by metal frame. The cartridge upper and lower fixed with cover and base. It has two types: one kind is inside and outside protected with galvanized steel plate; Another is the outer wall without galvanized steel plate protection, it is easy to dedusting.

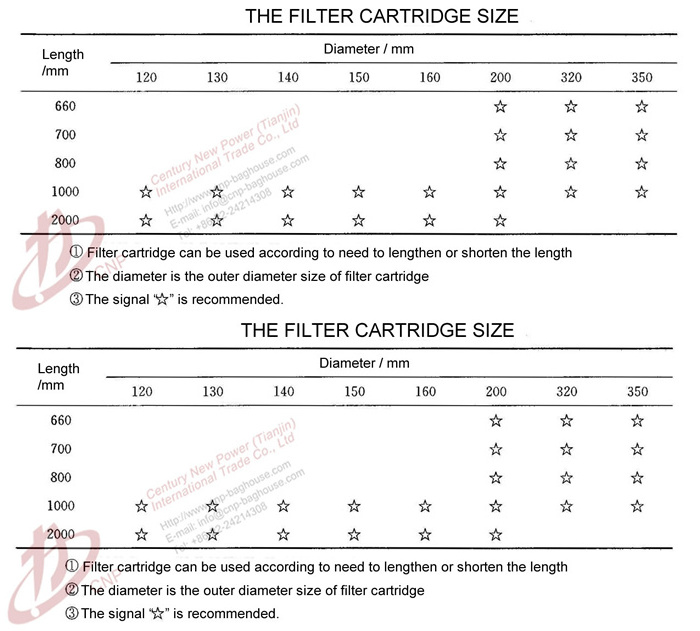

Specifications

The specifications of the commonly used diameter of the filter cartridge is 120-350mm, length is 660 - 2000mm. Please see the data as following:

Filter cartridge characteristic

The performance of the filter material include: physical and chemical properties, mechanical properties and filtration performance. For these performance, it takes physico-chemical properties of the fiber in filter, and the organizational structure of the filter material and manufacturing process, etc.

1. Physical and chemical property

After the selection of filter bag material and determine the specifications of the filter bag, we will process the filter bag as following attention matters:

(1) Quality. Quality generally called heavy cloth, it refers to the quality of area of filter material (g/to2). Due to the material and the structure of the filter material is the most intuitive to reflect on the quality, so the quality key to filter material performance is the most basic and the most important indicator.

(2) Thickness. Thickness is one of the physical properties. It is more influence on the permeability of filter material, wear resistance, etc.

(3) Density and heat resistance of heat-resistant.

(4) Electrostatic resistance. Gas movement or sit grain collision will make some filter material charged. The influence of the process is two aspects. One side is opposite charges attract. the dust particles from the air to the electric fungus instead of filter material movement, too big wide filtration efficiency. Adverse - surface electrostatic and cutting force is not necessarily at the end of the filter section disappear, make clear ash is difficult. In addition, due to the charged dust accumulation, higher static voltage, with ginger produced an explosion caused by spark. We keep the strict processing quality standards, according to design drawings and operation process. Our worker meet the requirements of tooling and clothing shoes and hats, no smoking.

Working occasions

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin

st Filter bag for High temperature cement industry dust collection waterproof application

- 1. Enquiries quickly reply within 24 hours.

- 2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

- 3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

- 4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

- 5. The bag filter equipment over 20 years working life.

- 6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

- 7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

- 8. Ensure easy operation and absolutely no worries about future