- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

425 cm³

-

Injection Rate (g/s):

-

503 g/s

-

Injection Weight (g):

-

379 g

-

Screw diameter (mm):

-

52 mm

-

Weight (KG):

-

10500

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

KF300-S6

-

Brand Name:

-

POWERJET

-

Power (kW):

-

21 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Overseas service center available, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Opening Stroke:

-

600mm

-

Injection Rate:

-

404g/s

-

Injection Weight:

-

399g

-

Power:

-

69.3KW

-

Product name:

-

Plastic Products Injection Molding Machine

-

Keyword:

-

Thin wall products Making Machine

-

Name:

-

IML injection molding machines

-

Certification:

-

CE, ISO

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

950 mm

-

Distance between Tie Bars(Height)(mm):

-

950 mm

-

Ejector Stroke(mm):

-

145 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

425 cm³

-

Injection Rate (g/s):

-

503 g/s

-

Injection Weight (g):

-

379 g

-

Screw diameter (mm):

-

52 mm

-

Weight (KG):

-

10500

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

KF300-S6

-

Brand Name:

-

POWERJET

-

Power (kW):

-

21 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Overseas service center available, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Opening Stroke:

-

600mm

-

Injection Rate:

-

404g/s

-

Injection Weight:

-

399g

-

Power:

-

69.3KW

-

Product name:

-

Plastic Products Injection Molding Machine

-

Keyword:

-

Thin wall products Making Machine

-

Name:

-

IML injection molding machines

-

Certification:

-

CE, ISO

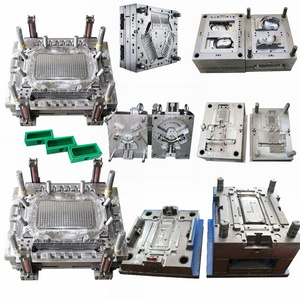

Powerjet released IML production system——PKF series

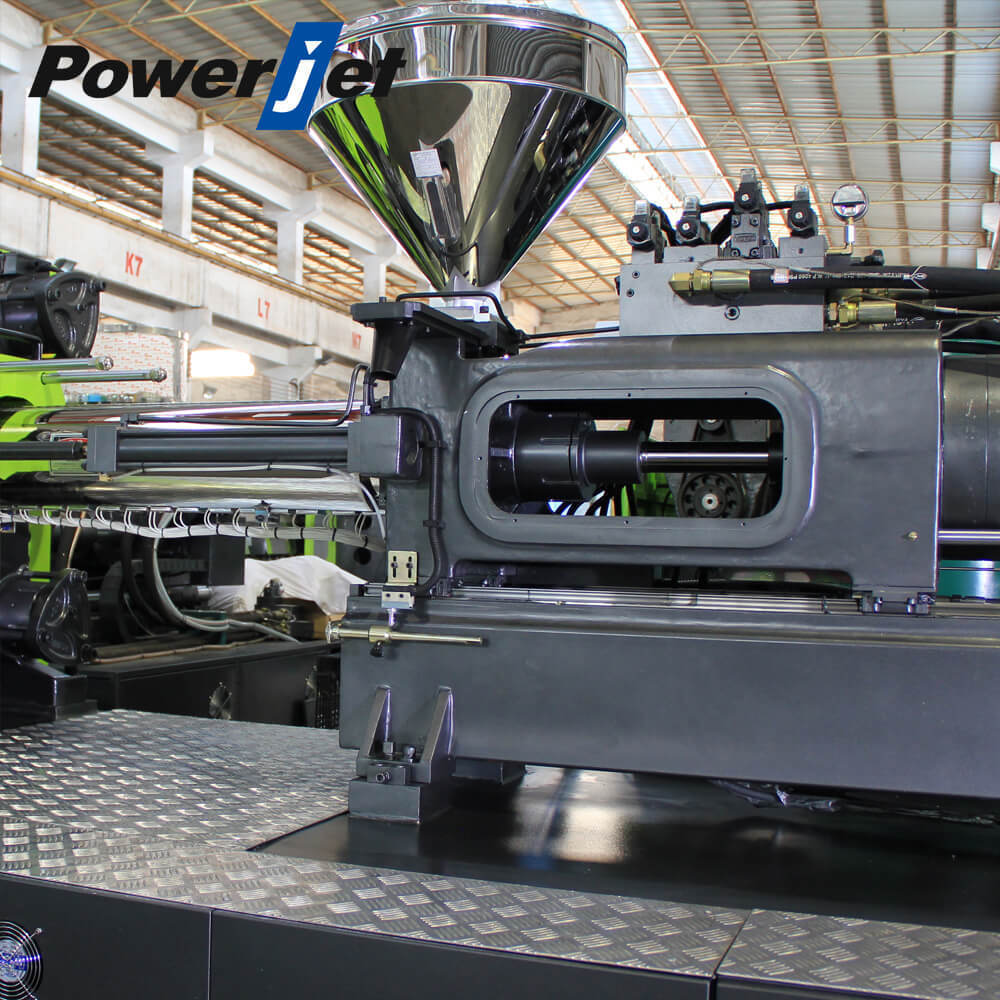

Based on KF series, which is mature, stable and widely accepted by the market, and aimed at the process and technical requirement of in-mold labeling, the struction is designed better in order to satisfy the requirement of the host machine, which has the advantages of high speed, high precision, and high stability.

1, High speed:

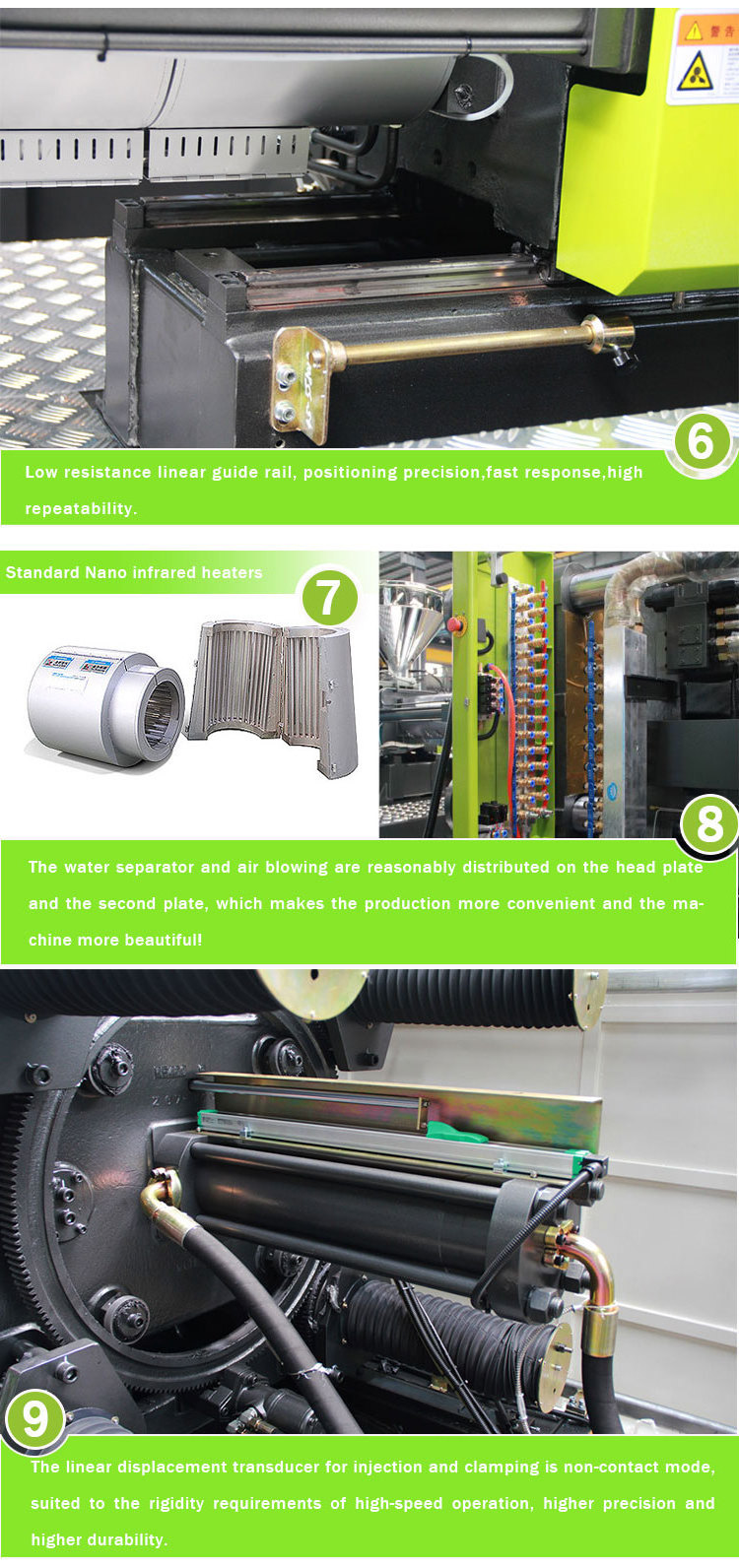

KF series is the basic platform of PKF series which is designed specially for thin-wall products. And the minimum thickness can achieve 0.25mm. Optional with accumulator can assist high-speed injection, and injection speed can exceed 650 mm/s.

2, High precision:

Standard configuration of closed-loop servo injection control makes the accumulator to be controlled precisely in injection process.

3, High stability:

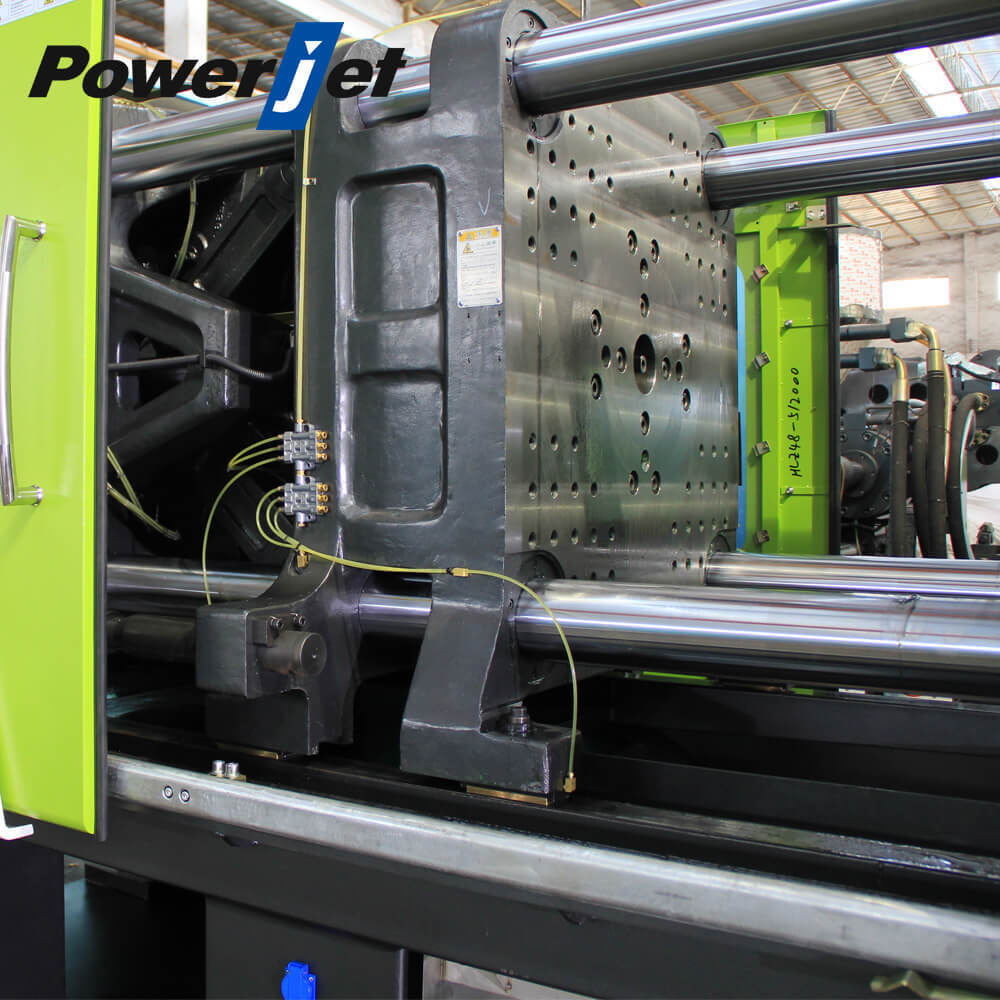

Low vibration, high rigidity frame construction, and precise close-loop servo opening mold displacement device ensure the repeatable precision in the high speed rotation process of sending labels and taking products.

The powerful function and accuracy can help customers reduce the weight of the products and shorten the cycle time. Compared with the present industry standard, Powerjet’s PKF IML automatic production system can reduce more than 10% product weight and shorten cycle time by 10%

Powerjet provides specialized injection molding machines dedicated to plastic cutlery products, such as: plastic spoons, forks and knives. We have improved the injection system to makes thin-wall products easier to solidify, and can save 30-50% of energy compared to common models.

KF series is our specialized injection molding machine for thin-wall products

FEATURES:

1:

Energy-Saving 30%~50%

Servo motor with energy-saving controlled hydraulic systems can save electricity up to 30%~50%.

2:

Low Temperature Injection

Low-Temperature Injection Makes More Energy Saving And Keeping Products With High Tenacity And Toughness By Our Innovative Plasticizing System.

3:

Low Pressure Injection

Low-Pressure Injection To Gain Better Mechanical Protection And Longer Mould Service Life. Also Makes Molding Products With Low Stress And Deformation.

4:

Fast Response Speed

Optimized Control System Response Speed Let Our Shooting Rate Reaching The Best Short Time Within 0.3 Seconds.

|

|

DESCRIPTION | UNIT | KF300-S6 |

| CLAMPING UNIT | Clamping force | KN | 3000 |

| Opening stroke | mm | 550 | |

| Max.datlight | mm | 1150 | |

| Platen size | mm | 950*900 | |

| Space between bars | mm | 620*570 | |

| Max.mold height | mm | 600 | |

| Min.mold height | mm | 250 | |

| Ejector stroke | mm | 145 | |

| Ejector force | KN | 77 | |

| INJECTION UNIT | Screw diameter | mm | 52 |

| Screw L/D Ratio | L/D | 22 | |

| Injection Pressure | MPa | 188 | |

| Shot volume | cm 3 | 425 | |

| Screw stroke | mm | 200 | |

| Screw speed | rpm | 300 | |

| POWER UNIT | Hydraulic system Pressure | MPa | 17.5 |

| Pump motor power | KW | 40+40 | |

| Heater power | KW |

21 |