- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGYA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7500x2500x3020mm

-

Weight (KG):

-

12800 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Power:

-

50.88KW

-

Advantage:

-

High Efficiency

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

12000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGYA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7500x2500x3020mm

-

Weight (KG):

-

12800 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Power:

-

50.88KW

-

Advantage:

-

High Efficiency

Shandong Shengya Machinery CO.,Ltd is specialized in manufacturing the concrete block making machine and clay brick making machine for more than 17 years since 1995.We have settled up 8 subsidiaies in Africa including Algeria,Tanzania,Cote d'Ivore,Kenya,Nigerua,Ethiopia,Cameroon,Senagal,which can make the after-sale service there.

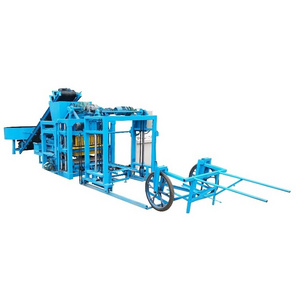

| Item | Automatic Hydraulic Block Forming Machine |

| Model | QT10-15 |

| Dimension | 7500x2500x3020mm |

| Power | 50.88kw |

| Vibration force | 100KN |

(1) Reasonable design, compact structure, strong rigidity, special welding process. Imported accessories are widely used to make the machine work stably and reliably.

(2) Efficient and powerful vibration system design, equipped with computer-controlled hydraulic system, to achieve vertical synchronous vibration, frequency conversion, braking, dual end synthetic output. The vibration force is evenly and quickly transmitted to the mold box, which greatly improves the density of bricks and the service life of the mold box.

(3) It is completely controlled by PLC control system to realize random signal analysis, fault diagnosis and parameter setting.

(4) Equipped with full-automatic palletizer to realize large-scale production and automatic operation. At the same time, it will also greatly reduce labor, protection area and investment.

(5) The semi closed forced spiral unloading system is adopted to make the feeding fast and uniform.

(6) The storage hopper and feed hopper are driven by closed electric rollers and separated in advance to prevent material liquefaction.

We have settled up eight subsidiaries in Africa including Algeria,Tanzania,Nigeria,Ethiopia,Cote d'Ivoire,Cameroon,Kenya,Senegal.

1.Nude packing

2.Iron case package