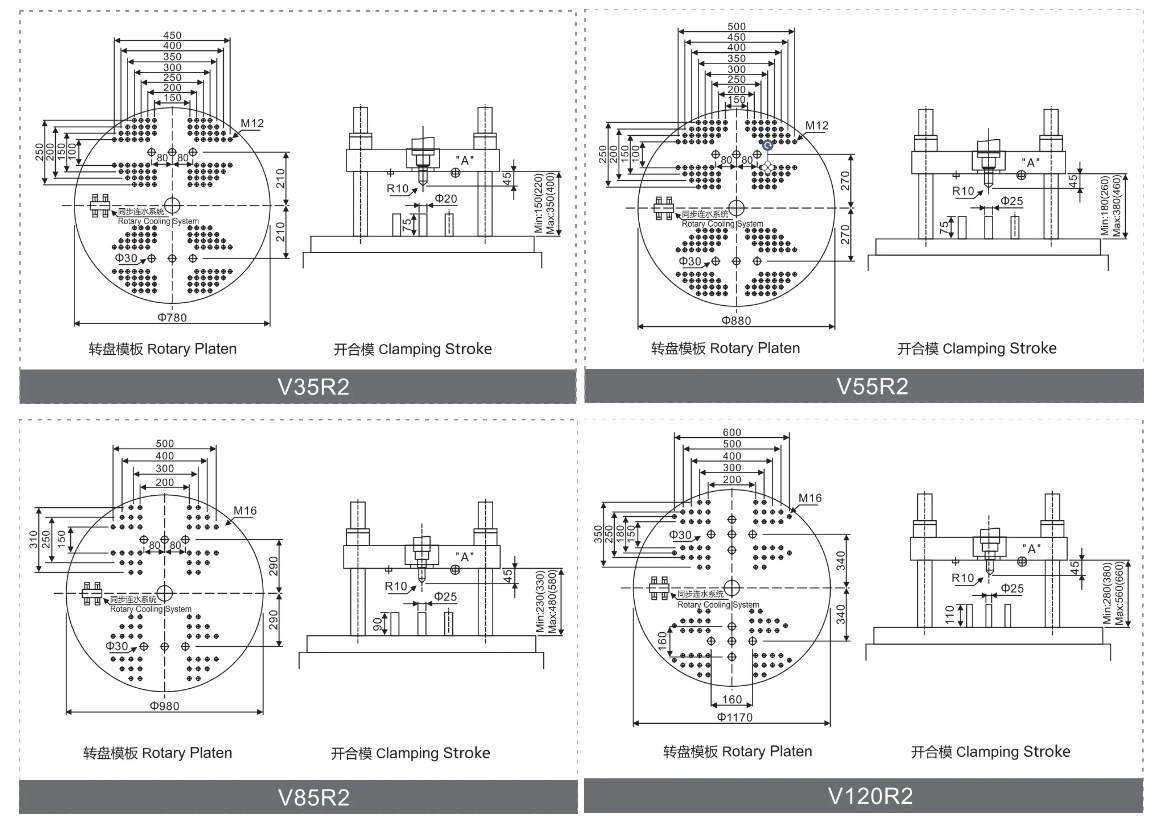

Clamping Force :20~500 TonInjection Capacity: 0.5~100 Oz

Main Features:

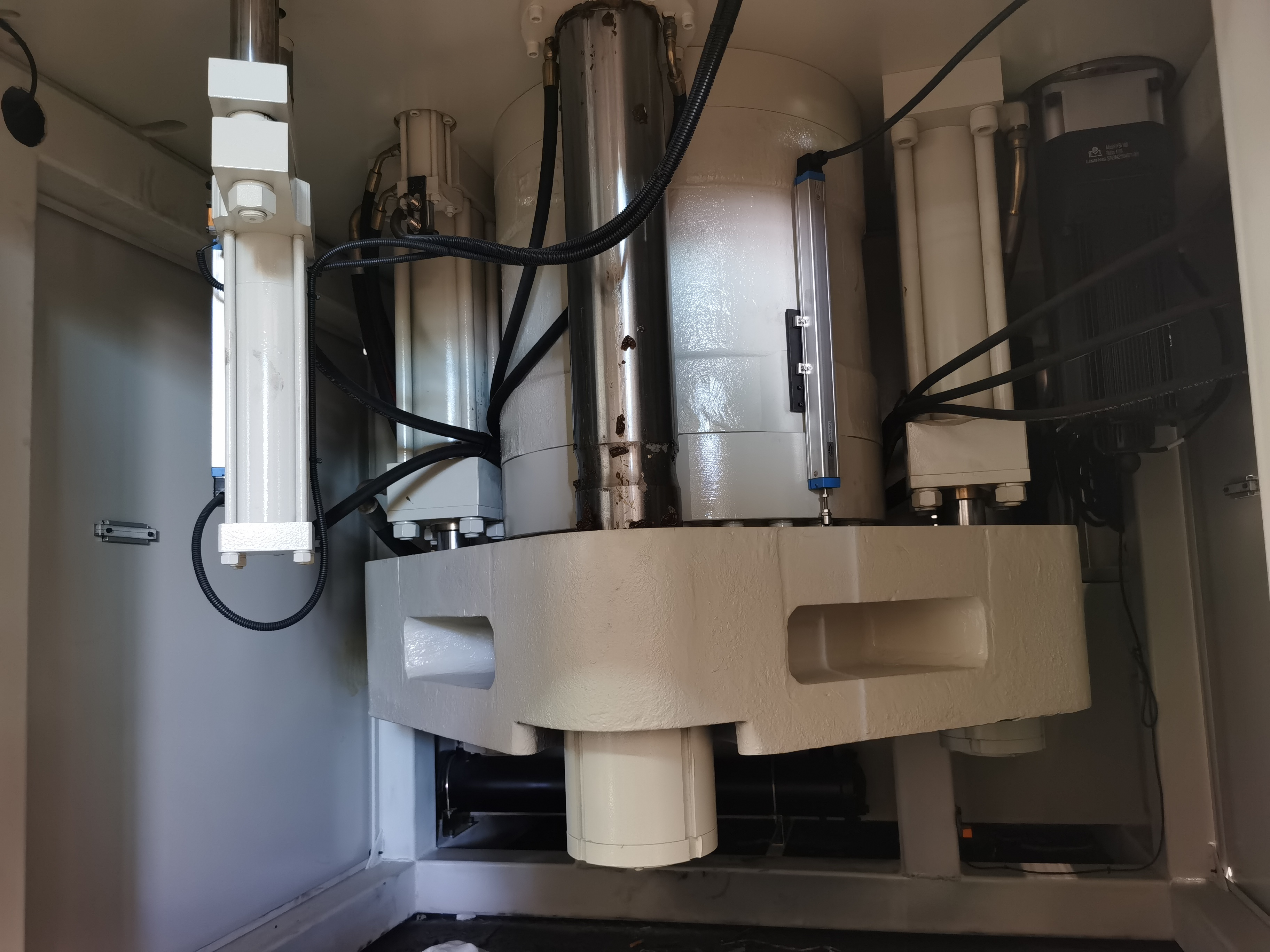

--Vertical clamping, vertical injection, easy to insert

--R2: 3-tie bar 2 station rotary table

R3: 4-tie bar 3 station rotary table

--Multi-station turn-plate (1 upper mold, 2-4 bottom molds) increase production capacity

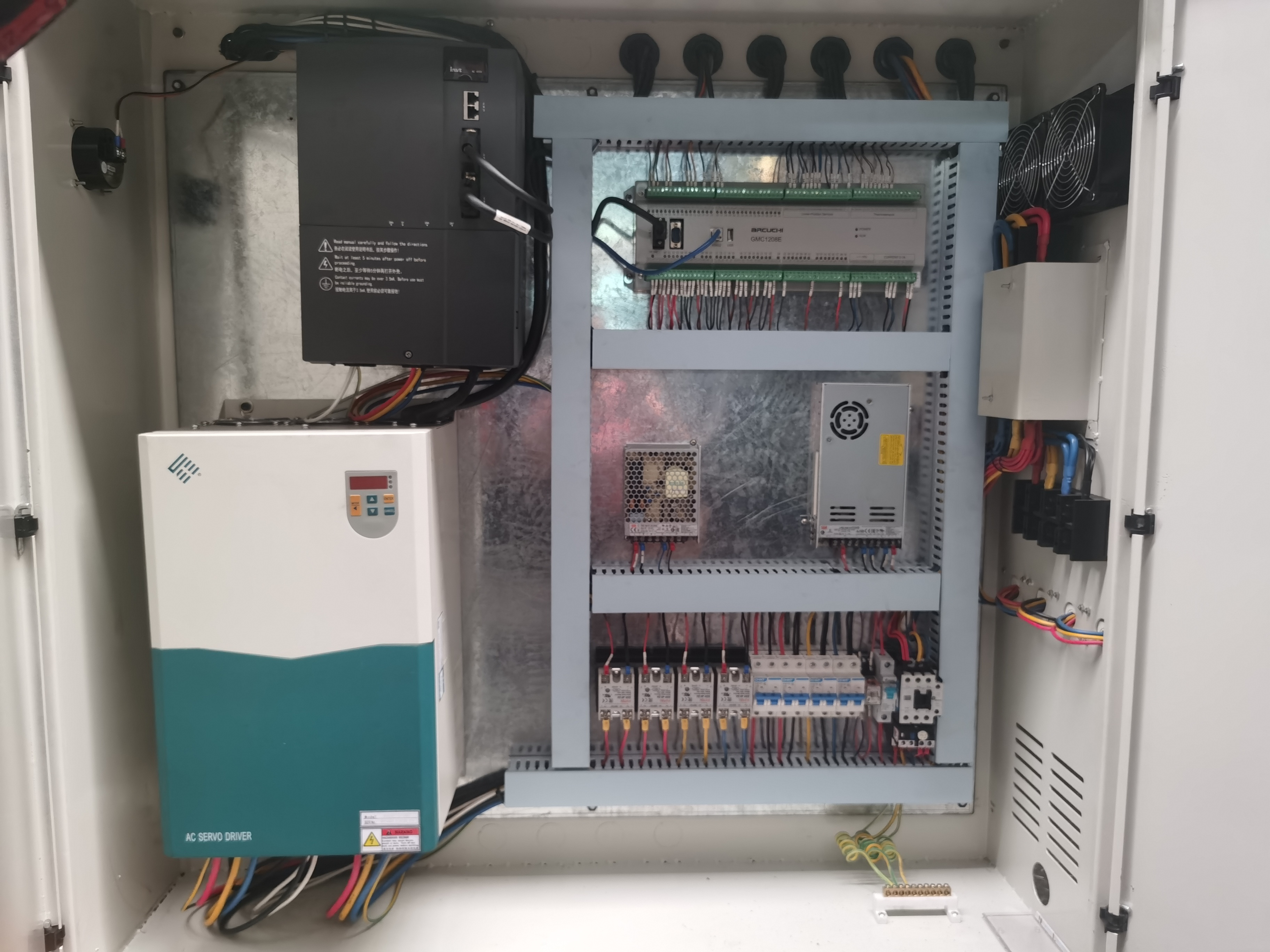

--Diversified hydraulic system (semi-closed loop, servo or high-speed injection) designs for different production needs