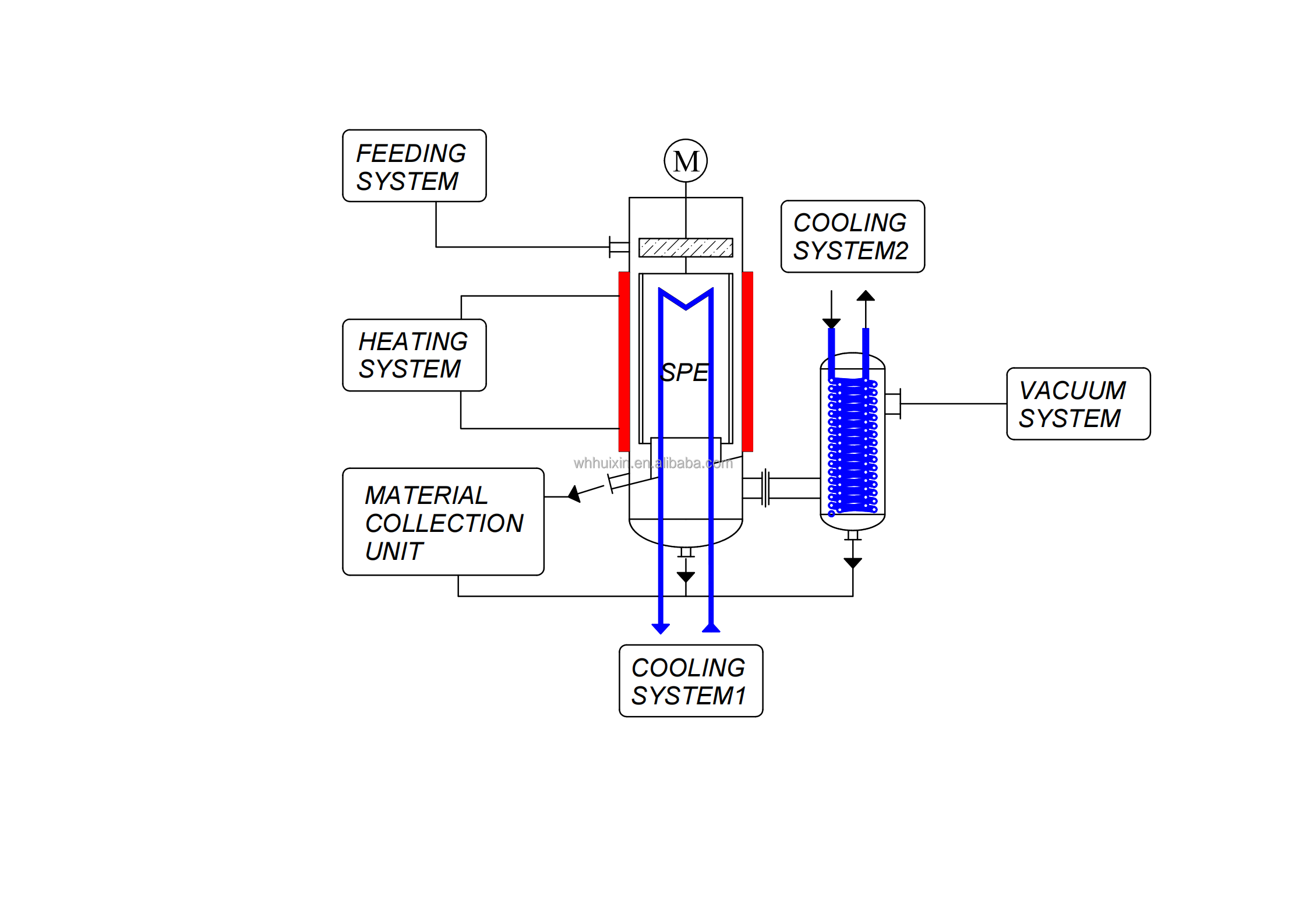

Basic Configuration

* Feeding system(including pre-heating and degassing stage)

* Short path evaporator(SPE)

* Cold trap

* Collection systems for distillate and residue

* Heating and cooling systems

* Vacuum system